Home > Dairy Fittings > TC Gasket

Harshita Stainless provides an exhaustive array of TC (Tri-Clamp) Gaskets in Delhi, India, for hygienic sealing of stainless steel process pipelines. The gaskets provide leak-proof, sanitary connections between ferrules and liners. We provide gaskets from FDA-approved materials including EPDM, silicone, PTFE, and Viton, to promote chemical compatibility as well as heat resistance. Both ease of cleaning and rapid installation are considerations in the design of our TC gaskets, which are applied in drug, dairy, food & beverages, and cosmetics production processes. Harshita Stainless offers dependable sealing solutions to customers who need utmost hygiene and regulatory compliance.

TC Gaskets come in materials such as EPDM, Silicone, PTFE, and Viton, each of which is chosen for a particular resistance to temperature, chemicals, or pressure. These materials have hardness ratings of 60–80 Shore A, temperature operating ranges from -50°C to +250°C, and very good compression set resistance. All gasket materials are FDA and USP Class VI compliant and thus safe to use in sanitary application. The non-reactive, flexible, and long-lasting character of these gaskets resists leakage, contamination, and system failure

Thickness : 1.0 mm to 5 mm, 16 SWG, 18SWG, 20 SWG, 12 SWG, 14SWG,

Sizes : DN 10 – DN 100, 1/2”-4”

Finish : Mechanical Polish, Electro Polished, 320 Grit, 500 Grit, 400 Grit, Non Electro Polished, 800 Grit

Outside Diameter : 1/4” N.B. – 8” N.B, 1/4” O.D. – 8” O.D.

Grade : SS 201, SS 202, SS 304L, SS 316, SS 304,SS 321,SS 316L, SS 310S, SS 904L

Standards : IDF / SMS / DIN / TRICLOVER / BSP / NPT

Contact us to get a quick quote for your requirement.

We tests the TC Gaskets with a comprehensive quality check. Pressure and leakage tests are also performed for compliance with industrial standards. Harshita Stainless guarantees the quality, reliability, and performance of TC Gaskets and provides perfect sealing in several industries.

SS 304 TC Gaskets are crafted from stainless steel 304, offering excellent corrosion resistance and durability. These gaskets are ideal for sanitary and industrial applications and are commonly used in food, beverage, and pharmaceutical industries.

Stainless Steel Triclover Gaskets are designed to create a secure, leak-proof seal between Tri-Clover fittings. Available in various stainless steel grades, they are perfect for sanitary processes, ensuring hygiene and safety in the food and pharmaceutical industries.

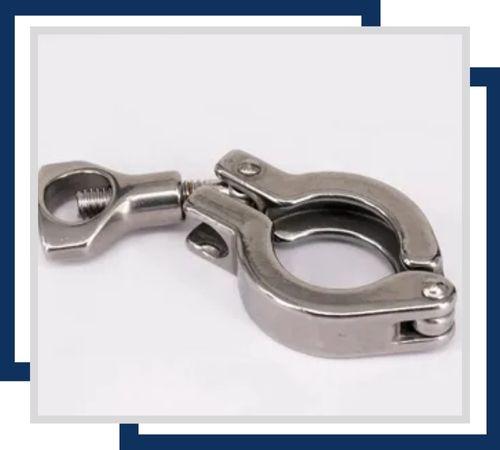

SS TC Clamp Gaskets are designed to fit Tri-Clamp fittings, providing a reliable seal between two clamp connections. Made from stainless steel, they are corrosion-resistant and suitable for high-pressure applications in food processing and pharmaceuticals.

316 SS Dairy TC Gaskets are made from 316 stainless steel, offering superior corrosion resistance and chemical compatibility. These gaskets are particularly suited for dairy applications, ensuring a hygienic and secure seal in dairy processing environments.

SS TC Long Sock Screen Gaskets combine a stainless steel gasket with a long sock screen for sealing and filtration. These gaskets are used in processes requiring secure connections and effective filtration of particulates, commonly in the pharmaceutical and food industries.

Stainless Steel TC Gaskets are versatile gaskets made from stainless steel, providing durable, corrosion-resistant seals in Tri-Clamp fittings. They are widely used across various industries and are suitable for high- and low-pressure applications.

TC Gaskets are used to ensure leak-free, hygienic joints in sanitary clamp systems. They find application in the biotech, pharma, food processing, and brewing industries. These gaskets close the gap between ferrules and liners, avoiding contamination of fluid systems. Both clean-in-place and manual cleaning methods are suitable for them. They provide quick installation with long-term reliability. Harshita Stainless provides TC gaskets throughout Delhi and India, enabling clients to maintain sterility and adhere to rigid regulatory guidelines in high-purity process situations.

©2024 Harshita Stainless All Rights Reserved.