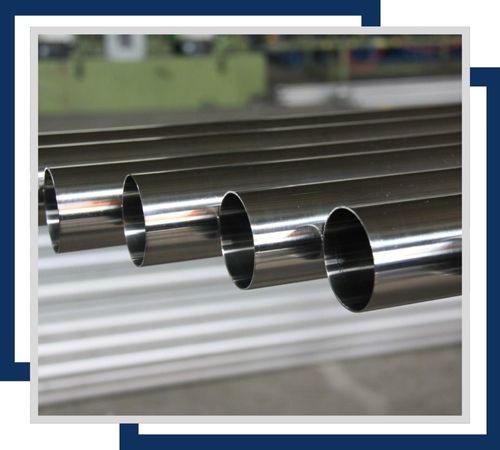

Delhi-based Harshita Stainless produces and offers high-quality Stainless Steel Welded Tubing for structural, mechanical, and sanitary usage. Our welded tubing is made by welding and rolling stainless steel strips with high precision, providing cost-effectiveness, uniform wall thickness, and high strength. Our tubing solutions come in numerous grades, diameters, and surface finishes and are applied across various industries. Harshita Stainless maintains stringent quality control and adherence to international standards and provides corrosion-resistant and long-lasting welded tubing throughout India.

Our welded tubing is offered in 304, 304L, 316, and 316L grades. These are 18–20% chromium and 8–12% nickel and have optional molybdenum for added resistance to corrosion. The tubing has tensile strength of 500–750 MPa, yield strength of 200–350 MPa, and elongation up to 40%. Welded tubes exhibit very good dimensional control and surface finish. They are appropriate for high to moderate pressure applications, are thermally stable, and pitting and crevice corrosion resistant, which makes them perfect for industrial applications.

| Range : | 1/8” NB to 36” NB, 1/4” OD to 36” OD |

|---|---|

| Outer Diameter : | 6.35 mm O.D to 114.3 mm O.D |

| Thickness : | 0.8 mm to 12.7 mm |

| Length : | up to 26 Meters |

| Specifications : | ASTM A312 / ASTM SA312 |

| Types : | As Welded, EFW, ERW |

| End : | Plain End, Beveled End |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304 | min. max. | – 0.08 | – 2.0 | – 0.75 | – 0.045 | – 0.030 | 18.0 20.0 | – | 8.0 10.5 | – 0.10 |

| 304L | min. max. | – 0.030 | – 2.0 | – 0.75 | – 0.045 | – 0.030 | 18.0 20.0 | – | 8.0 12.0 | – 0.10 |

| 304H | min. max. | 0.04 0.10 | – 2.0 | – 0.75 | -0.045 | – 0.030 | 18.0 20.0 | – | 8.0 10.5 | – |

| Element | SS 304 |

|---|---|

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Elongation | 35 % |

Contact us to get a quick quote for your requirement.

Stainless steel welded tubing are formed by welding stainless steel strips or plates. They offer strength, corrosion resistance, and cost-effectiveness, suitable for various industrial, commercial, and residential applications.

Stainless steel ERW (Electric Resistance Welded) tubing are produced by welding steel strips. They offer cost-effective, high-strength, and corrosion-resistant solutions for various industrial applications, providing durability and reliability.

Stainless Steel EFW (Electric Fusion Welded) tubing are produced by electrically fusing stainless steel plates or strips. They offer high precision and strength, suitable for high-pressure and demanding applications.

SS HFW (High-Frequency Welded) tubing are stainless steel tubings welded using high-frequency currents. They provide strong, precise joints, making them ideal for structural applications and high-strength requirements.

Stainless Steel butt-welded tubing are joined by aligning and welding the ends together. This method creates strong, leak-proof joints, ideal for high-pressure and high-temperature applications in various industries.

Stainless Steel laser-welded tubing use laser technology for precise, clean welds. They offer high accuracy, minimal thermal distortion, and are ideal for applications requiring tight tolerances and smooth finishes.

The tests include destructive testing methods and others which do not destroy the material but analyze the testing quality. We are developing into all modern aspects. Offering services to any customer that provides security assurance, we live achievement and a few policies such as consideration of diversity and advantage of best quality, quality reputation, and our name in the industry. Best quality speaks for itself, especially when the customer is satisfied after delivery. Logistical support at the most convenient part to ensure that shipping for emergency stock and standard packing materials is done correctly.

Stainless steel welded tubing finds extensive use in furniture, railings, heat exchangers, boiler tubes, and exhaust systems of vehicles. It‘s also utilized in chemical processing, food and beverage, and water treatment plants. These welded tubes are used for structural support, process piping, and equipment structures because of their strength, consistency, and resistance to environmental factors. Harshita Stainless welded tubes in Delhi and throughout India provide customers with affordable, high-performance tubing with consistency and ease of fabrication.

©2024 Harshita Stainless All Rights Reserved.