Home > Electrodes > Stainless Steel Electrodes

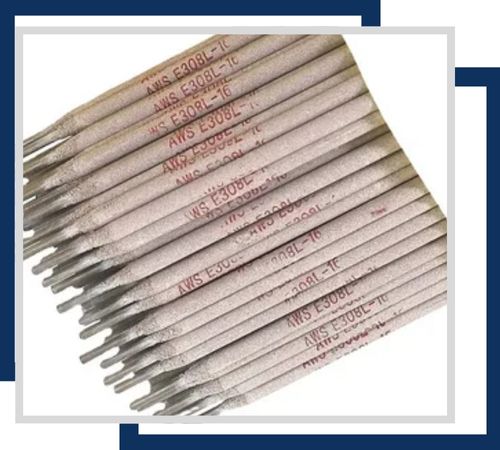

Harshita Stainless provides high-performance Stainless Steel Electrodes in Delhi, India, to serve welding and fabrication needs in industrial sectors. These electrodes are designed for excellent arc stability, low spatter, and high deposit efficiency. High-grade stainless steel alloys such as SS 308, 309, 316, and 347 are used to produce them, offering them high corrosion and oxidation resistance. Suitable for welding stainless steel tanks, pipelines, and structures, our electrodes comply with demanding welding requirements. Harshita Stainless offers consistent quality, technical specifications, and performance in each batch to cater to manufacturing, maintenance, and construction industries.

SS electrodes consist of chromium (18–22%), nickel (8–12%), and occasionally molybdenum for enhanced resistance. Types such as E308, E309, and E316 are standard. They provide tensile strength over 550 MPa and yield strength at around 300 MPa. The electrodes have good arc stability and slag removal, and deposit sound welds free from cracks or porosity. Mechanical properties differ with grade but provide strength, ductility, and corrosion resistance for varied fabrication work.

| Specifications | AWS A5.14 ERNiCr-3, AWS A5.11 ENiCrFe-3 |

| International Specifications | BS 3072-3076 (NA14) DIN 17742, DIN 17750, DIN 17754 WERKSTOFF Nr 1.4301 TÜV 305 AFNOR-NC 15 Fe |

| Size | 2.00 mm Dia., 2.50 mm Dia., 3.15 mm Dia., 4 mm Dia., 5 mm Dia., 6.3 mm Dia. |

| Length | 300 mm to 450 mm |

| Model | Chemical Composition | |||||||||

| C | Mn | Si | S | P | Cr | Ni | Mo | Cu | Nb | |

| AWS E308-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | — |

| AWS E308L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | — |

| AWS E309-16 | 0.15 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.75 | — |

| AWS E309L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.75 | — |

| AWS E309MoL-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 2.0-3.0 | 0.75 | — |

| AWS E310-16 | 0.08-0.20 | 1.0-2.5 | 0.75 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 | — |

| AWS E312-16 | 0.15 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.75 | — |

| AWS E316-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.75 | — |

| AWS E316L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.1 | 0.75 | — |

| AWS E318-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.2 | 0.75 | 6xC-1.00 |

| AWS E347-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | 8xC-1.00 |

| AWS E410-16 | 0.12 | 1 | 0.9 | 0.03 | 0.04 | 11.0-13.5 | 0.7 | 0.75 | 0.75 | — |

| Model | Machanical Properties of Deposited Metal | |||

| Tensile Strength | Elongation | |||

| (Mpa) | (%) | |||

| AWS E308-16 | >550 | >35 | ||

| AWS E308L-16 | >520 | >35 | ||

| AWS E309-16 | >550 | 25 | ||

| AWS E309L-16 | >550 | >25 | ||

| AWS E309MoL-16 | >540 | >25 | ||

| AWS E310-16 | >550 | >25 | ||

| AWS E312-16 | >660 | >22 | ||

| AWS E316-16 | >520 | >30 | ||

| AWS E316L-16 | >490 | >30 | ||

| AWS E318-16 | >550 | >25 | ||

| AWS E347-16 | >550 | >25 | ||

| AWS E410-16 | >450 | >20 | ||

Contact us to get a quick quote for your requirement.

Designed for excellent corrosion resistance, these electrodes are ideal for thin stainless steel sections and are typically available in sizes like 1.6mm to 4.0mm in diameter. Their light coating provides good penetration and easy handling.

These electrodes offer superior corrosion resistance and are used for thicker stainless steel sections. They come in larger sizes, ranging from 3.2mm to 5.0mm in diameter, and their heavy coating ensures enhanced arc stability and better fill rates.

Providing outstanding corrosion resistance, these electrodes are used in shielded metal arc welding. They are available in various sizes, including 2.0mm to 4.0mm, and are known for their high-quality welds and resistance to high-temperature environments.

Choose stainless steel electrodes based on the base material’s grade, application (corrosion, heat, or strength requirements), and welding position. Ensure compatibility with the operating environment and desired mechanical properties.

Yes, you can order Stainless Steel Electrodes in custom sizes and polishes to meet your specific requirements. For more details, mail us at sales@harshitastainless.co.in

Stainless steel electrodes typically do not require additional corrosion protection coatings because they inherently resist corrosion due to their chromium content. However, coatings may be applied in extreme environments for added protection.

Yes, stainless steel electrodes can be used in cryogenic applications due to their excellent toughness and strength at low temperatures, along with superior corrosion resistance. They are ideal for welding materials exposed to cryogenic environments.

Stainless Steel Electrodes are applied for pipeline welding, pressure vessels, chemical storage tanks, and fabrication of equipment. They find application in welding stainless steel sheets, plates, and structural components in industries such as petrochemical, power generation, shipbuilding, and construction. The electrodes preserve the corrosion resistance of the base metals and provide high-quality welds under field and workshop environments. Harshita Stainless also provides electrodes all over Delhi and India, serving industries requiring precision and toughness in welded joints and stainless steel structures.

©2024 Harshita Stainless All Rights Reserved.