Harshita Stainless is a reputable manufacturer and supplier of top-notch Stainless Steel 904L Bars, proudly based in Delhi, India. They’ve built a solid reputation for providing products that excel in corrosion resistance, with their 904L bars meeting international quality standards and serving a variety of industrial needs. Crafted with precision and cutting-edge technology, these bars go through strict quality checks to guarantee their durability and performance. Stainless Steel 904L is a high-alloy austenitic stainless steel known for its remarkable resistance to strong reducing acids and stress corrosion. Harshita Stainless is dedicated to offering dependable and cost-effective solutions for the chemical, marine, and power generation sectors.

| Standards | ASTM / ASME |

| Designation | B 649, SB 649 |

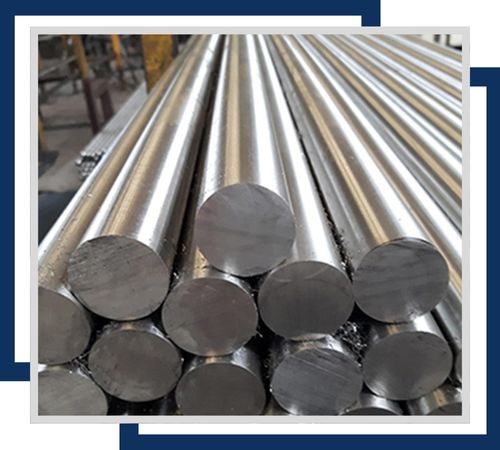

| Grade | 904L Round Bars and Rods 904L Round Bars and Rods: ASTM B 649, ASME SB 649 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| SS 904L | 0.020 max | 2 max | 1 max | 0.040 max | 0.030 max | 19.0-23.0 | 4.0-5.0 max | 23.00 – 28.00 | 1.0-2.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35% |

Contact us to get a quick quote for your requirement.

The composition of Stainless Steel 904L includes about 19–23% chromium, 23–28% nickel, 4–5% molybdenum, 1–2% copper, and low carbon content, all of which boost its corrosion resistance and weldability. This alloy boasts a tensile strength of around 490 MPa, a yield strength of 220 MPa, and an elongation of 35%. Thanks to its high nickel and molybdenum content, it shows excellent resistance to pitting and crevice corrosion, particularly in environments rich in chloride. Stainless Steel 904L bars maintain their mechanical stability across a broad temperature range, making them perfect for tough conditions involving strong acids and high stress.

904L round bars offer high resistance to corrosion and oxidation, ideal for harsh environments in chemical processing, marine, and pharmaceutical industries, providing durability and strength.

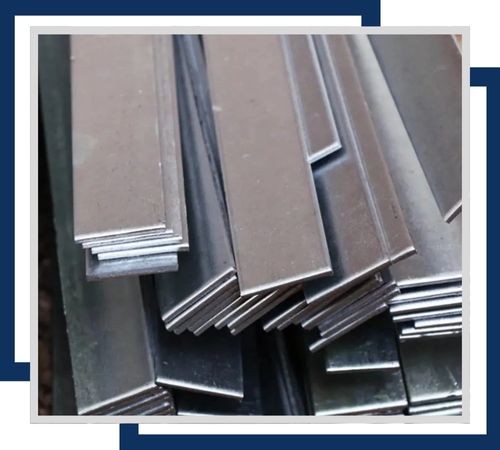

904L flat bars provide exceptional resistance to pitting and crevice corrosion, suitable for use in aggressive environments like chemical processing and marine applications, ensuring robust performance and longevity.

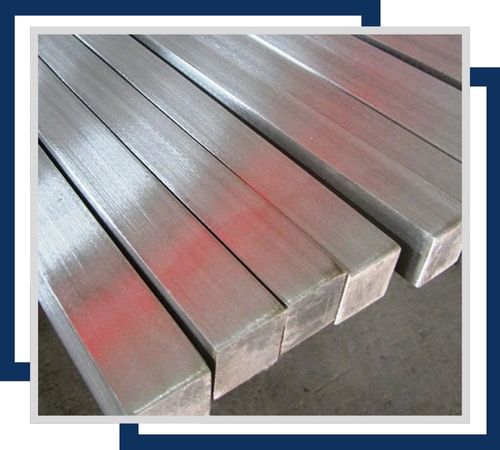

904L square bars deliver superior corrosion resistance and strength, perfect for structural applications in corrosive environments, such as chemical plants and marine environments, offering durability and reliability.

904L rectangular bars are designed for high corrosion resistance and strength, used in chemical processing, marine, and industrial applications, where durability and performance under harsh conditions are required.

904L hexagonal bars provide excellent corrosion resistance and are used in structural and mechanical applications, particularly in aggressive environments such as chemical processing and marine settings.

904L T-bars offer superior resistance to corrosion and high strength, ideal for structural support in corrosive environments like chemical plants and marine applications, ensuring long-lasting performance and reliability.

Harshita Stainless is a leading supplier, and stockist of high-quality stainless steel 904L bars in Dubai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

These Stainless Steel 904L Bars are extensively utilized in industries that demand outstanding corrosion resistance and structural integrity. You’ll find them in applications like chemical processing equipment, heat exchangers, acid production facilities, and the pulp and paper sector. They’re also essential in marine engineering, pharmaceutical processing, seawater cooling systems, and oil and gas platforms due to their ability to withstand chloride stress corrosion cracking and harsh chemicals. Their non-reactive properties make them ideal for handling sulfuric, phosphoric, and acetic acids. With their excellent formability and weldability, 904L bars are the go-to choice for fabrication projects that require a long service life and minimal maintenance.

©2024 Harshita Stainless All Rights Reserved.