Stainless Steel 443 Tubing is a type of ferritic stainless steel that stands out for its impressive corrosion resistance, thermal conductivity, and affordability. It was designed as a cost-effective alternative to austenitic grades like 304, particularly in settings where moderate corrosion resistance is needed without breaking the bank. Thanks to its good formability, oxidation resistance, and thermal fatigue strength, SS 443 tubing is perfect for applications that demand strength and durability in mildly corrosive or high-temperature environments. Plus, its low nickel content makes it a more stable choice in terms of pricing, all while providing reliable performance across a range of industrial and structural uses.

When it comes to its chemical makeup, Stainless Steel 443 typically features 17.5–20% chromium, less than 0.03% carbon, and small amounts of molybdenum, niobium (for stabilization), and titanium. It has very little nickel (usually under 1%), which helps keep costs down while still offering solid corrosion resistance. On the mechanical side, SS 443 boasts a tensile strength of about 450 MPa and a yield strength around 275 MPa, along with moderate elongation and good workability. Its ferritic microstructure not only enhances resistance to chloride stress corrosion cracking but also improves high-temperature oxidation resistance compared to standard ferritic steels.

| Specifications | ASTM A240, ASME SA240 |

| Standard | JIS, ASTM, AISI, GB, EN, DIN |

| Surface | 2B, 2D, BA, NO.4, NO.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Finish | Cold rolled,/Hot rolled |

| Width | 1000mm-2000mm |

| Length | 1000mm-6000mm |

| Thickness | 0.40mm – 6.00mm |

| C | Si | Mn | P | S | Cr | Ni | Mo | Other |

| ≤0.030 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.015 | ≤17.5-18.5 | ——– | ———- | Ti 0.10-0.60 Nb 3*(C+0.30)-1.00 |

| Yield Rp0.2(MPa) | Tensile Rm(MPa) | Impact KV/Ku (J) | Elongation A (%) | Reduction in cross section on fracture Z (%) | As-Heat-Treated Condition | Brinell hardness (HBW) |

| 168 (≥) | 185 (≥) | 13 | 44 | 44 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 221 |

Contact us to get a quick quote for your requirement.

We rigorously test Stainless Steel 443 Tubing to ensure excellent quality and performance. Our products meet international standards with certifications such as ISO 9001, ASTM compliance, and traceability. Each tube is tested for durability, corrosion resistance and accuracy, providing reliability and excellent results for a variety of applications.

This tubing offers excellent corrosion resistance and is available in sizes ranging from 1/8″ to 24″ in diameter. It’s ideal for high-pressure applications due to its seamless construction, ensuring uniform strength throughout.

Known for its superior corrosion resistance, this tubing comes in sizes from 1/8″ to 36″ in diameter. The welded joints are precisely crafted, making it suitable for various structural and fluid transport applications.

With sizes ranging from 1/8″ to 24″ in diameter, this tubing is designed to withstand high temperatures and corrosive environments. It’s commonly used in heat exchangers due to its excellent thermal conductivity and corrosion resistance.

Available in sizes from 1/8″ to 2″ in diameter, this tubing is ideal for precision instruments. It offers excellent corrosion resistance and is designed for high-pressure and high-purity applications.

These tubes are available in sizes from 1/2″ to 5″ in diameter and are specifically designed to withstand high-pressure and high-temperature conditions. They provide excellent corrosion resistance, making them suitable for boiler applications.

Offering excellent corrosion resistance, these tubes are available in various sizes and are bent into U shapes for use in heat exchangers. The precision bending ensures efficient heat transfer and minimal stress points.

This tubing comes in sizes from 1/4″ to 3″ in diameter and is designed for use in condensers. It provides excellent corrosion resistance and thermal conductivity, making it ideal for heat exchange processes.

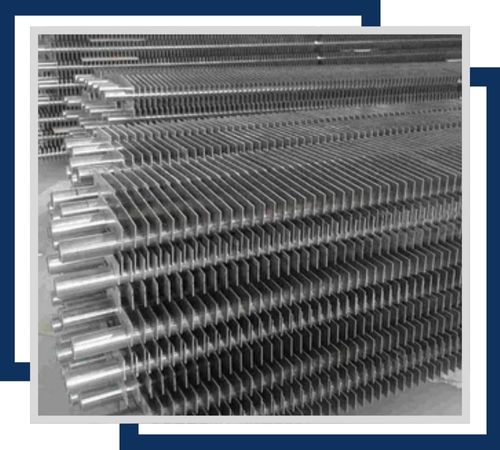

These tubes, available in sizes from 1/4″ to 2″ in diameter, have fins attached to increase surface area for better heat transfer. They offer superior corrosion resistance and are used in various heat exchanger applications.

You’ll find Stainless Steel 443 Tubing in a variety of applications, including heat exchangers, automotive exhaust systems, kitchen equipment, water heaters, architectural structures, and air conditioning systems. It’s especially well-suited for situations that require heat and corrosion resistance without the hefty price tag of austenitic stainless steels. Its formability and weldability make it a breeze to fabricate and bend, while its resistance to scaling at high temperatures makes it ideal for thermal processing and heating elements. Overall, SS 443 tubing strikes a great balance between performance, durability, and cost for both industrial and commercial applications.

©2024 Harshita Stainless All Rights Reserved.