Harshita Stainless Manufacturer and Suppliers, located in Delhi, India, stands out as a prominent player in the stainless steel sector, providing a diverse range of top-notch products that align with global standards. As a reliable manufacturer of stainless steel 440C coils in Dubai, India, the company has built a reputation for its unwavering commitment to quality, innovative production techniques, and a customer-first mindset. With years of expertise and a robust distribution network, Harshita Stainless offers high-performance stainless steel coils designed to meet the unique needs of various industries, including automotive, aerospace, tooling, and engineering. The company prioritizes precision, durability, and timely delivery to ensure that customers are completely satisfied.

The stainless steel 440C coils crafted by Harshita Stainless in Dubai, India, are made from high-carbon martensitic stainless steel, featuring about 16–18% chromium and 0.95–1.20% carbon. This specific blend provides remarkable hardness, strength, and wear resistance while still offering moderate corrosion resistance. The mechanical properties boast a tensile strength of roughly 760–965 MPa and a yield strength of around 450 MPa. 440C stainless steel can be heat-treated to reach its peak hardness and is designed to perform well in high-friction, high-load situations. Its machinability and polishability make it a go-to choice for precision parts and components.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Mn | Si | S | P | Cr |

| SS 440C | 0.20 max | 1.00 max | 1.00 max | 0.030 max | 0.040 max | 15.00 – 17.00 |

| lement | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness |

| SS 440C | 7.8 g/cm3 | MPa – 380 | MPa – 170 | 20 % | Rockwell B (HR B)- 88 / Brinell (HB)- 0.5t |

Contact us to get a quick quote for your requirement.

SS 440C slitting coils are highly durable and corrosion-resistant, ideal for precision components like cutting tools and bearings. Their hardness and wear resistance make them suitable for demanding industrial applications.

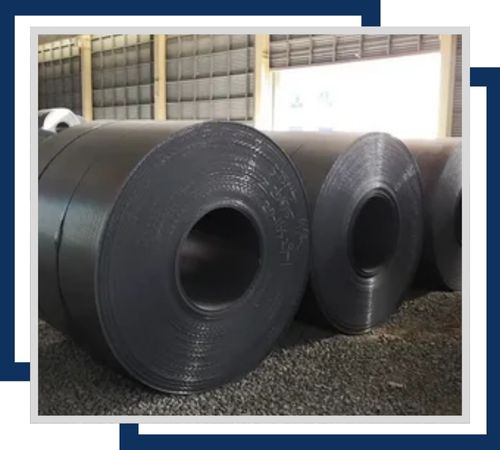

SS 440C hot rolled coils offer exceptional hardness and strength, making them ideal for high-stress applications. They are commonly used in manufacturing cutting tools, bearings, and automotive components.

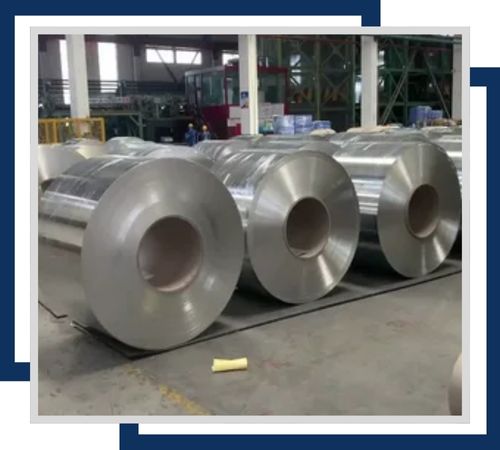

SS 440C cold rolled coils provide superior surface finish and dimensional accuracy. Ideal for precision applications, they are used in cutting tools, bearings, and other components requiring high hardness and durability.

Stainless Steel 440C HR slitting coils offer exceptional hardness and strength, making them perfect for precision-cutting tools and high-stress applications. Their durability and wear resistance enhance performance in demanding environments.

Stainless Steel 440C slitting coils provide excellent hardness and wear resistance, ideal for precision applications. Their durability and corrosion resistance make them suitable for high-stress components like cutting tools and bearings.

AISI 440C slitting coils are known for their high hardness and wear resistance. They are ideal for precision components such as cutting tools and bearings, offering durability and reliable performance.

We ensure complete transparency in delivering Stainless Steel 440C Coils with exceptional quality assurance. With every order, we provide essential documentation such as a commercial invoice, packing list, fumigation certificate, heat treatment chart, and a NABL-approved lab test report. We also offer a Material Test Certificate as per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. Our documentation is carefully organized to ensure maximum client satisfaction.

As a trusted manufacturer of stainless steel 440C coils in Dubai, India, Harshita Stainless supplies coils that are extensively utilized in demanding applications like ball bearings, valve components, cutting tools, surgical instruments, and high-stress mechanical parts. Thanks to their outstanding edge retention and surface hardness, 440C coils are perfect for scenarios where both strength and wear resistance are essential. These coils are also employed in aerospace assemblies, defense equipment, and industrial processing tools. With their adaptability, high performance, and resistance to corrosion and abrasion, SS 440C coils are a reliable choice for a wide range of applications.

©2024 Harshita Stainless All Rights Reserved.