Harshita Stainless makes and offers Stainless Steel 439 Tubing in Delhi, India. Grade 439 is a ferritic stainless steel alloy with stabilized titanium for improved oxide stability. The tubes are seamless or welded, as per ASTM standards. Providing corrosion resistance, thermal stability, and protection against oxidation, SS 439 tubing is suitable for exhaust systems and industrial heaters. Harshita Stainless provides tight tolerance and strong manufacturing for efficient tubing in India.

SS 439 has 17–19% chromium, 0.5% titanium, and minimum nickel. Tubing provides tensile strength of 450–600 MPa and yield strength of 200–250 MPa. Ferritic structure provides oxidation resistance to 600 °C and low coefficient of thermal expansion. Tensile and yield properties are sustained in high-temperature cycling.

| GRADES | TP 439 Stainless Steel Tubes / UNS S43035 / DIN 1.4510 |

| SIZE | 1/2″ NB to 24″ NB |

| STANDARDS | ASTM A213, ASTM A249, ASTM A554, ASTM A269, ASTM A270, ASTM A790, ASTM A789 |

| TYPE | Seamless Tubes, Welded Tubes, EFW Tubes, ERW Tubes, Fabricated Tubes, Cold Drawn Welded Tubes (CDW Tubes) |

| FORM | Round Tubes, Square Tubes, Rectangular Tubes, Oval Tubes, Hydraulic Tube, etc. |

| END | Plain End, Treaded, Beveled End |

| TOLERANCE on Length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| FINISH | Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm, Polished Grit 120 – 600, Mirror Polished |

| Element | 439 |

| Carbon | 0.030 |

| Chromium | 17.0-19.0 |

| Nickel | 0.50 |

| Manganese | 1.00 |

| Silicon | 1.00 |

| Nitrogen | 0.030 |

| Phosphorus | 0.040 |

| Sulfur | 0.030 |

| Aluminum | 0.15 |

| Titanium | 0.20 +4(C+N) min |

| Property | 439 |

| Yield Strength, min. (ksi) | 30 |

| Tensile Strength, min. (ksi) | 60 |

| Elongation, min. (%) | 22 |

| Hardness, max. (Rb) | 89 |

Contact us to get a quick quote for your requirement.

This tubing is manufactured without any seams or welds, ensuring a uniform structure and high strength. It is available in a range of sizes, typically from 1/8 inch to 4 inches in diameter. Known for its excellent corrosion resistance and durability in high-temperature applications.

Produced by welding flat sheets of stainless steel into a tube shape, this option is often more cost-effective than seamless tubing. It is available in sizes ranging from 1/4 inch to 8 inches in diameter. Offers good corrosion resistance and is suitable for less demanding environments.

Designed for use in heat exchangers, this tube type features enhanced thermal conductivity and resistance to thermal cycling. Commonly available in sizes from 1/2 inch to 2 inches in diameter. It provides good corrosion resistance and thermal stability.

Ideal for precise measurement and control applications, this tubing is available in small diameters, typically from 1/16 inch to 1 inch. It offers high corrosion resistance and maintains integrity under high pressure and temperature conditions.

Used in boilers for transporting steam and other fluids, these tubes are available in sizes from 1 inch to 4 inches in diameter. They are highly resistant to oxidation and corrosion at elevated temperatures.

Shaped in a U-form, these tubes are used in applications where a flexible connection is needed, often in heat exchangers. They come in sizes from 1/2 inch to 2 inches in diameter. Known for their resistance to corrosion and ability to handle thermal expansion.

This tube type is used in condensers for heat exchange processes, typically available in sizes ranging from 1/2 inch to 2 inches in diameter. It offers high resistance to corrosion and fouling in challenging environments.

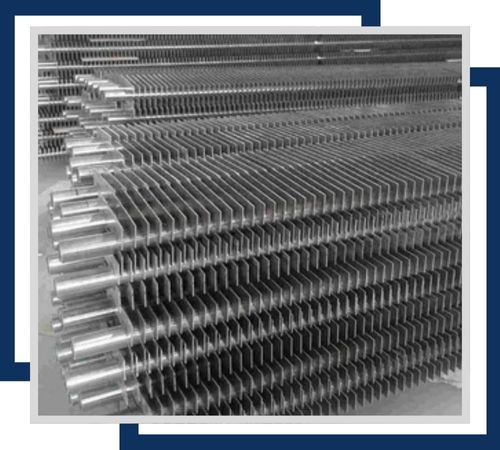

Equipped with fins to enhance heat transfer efficiency, these tubes are available in various sizes, commonly from 1 inch to 3 inches in diameter. They offer good corrosion resistance and are used in applications requiring efficient heat dissipation.

439 tubing is applied in industrial furnace coils, automotive exhausts, heat exchanger tubes, boiler economizers, and steam generators. Suitable for use in applications with moisture and high temperature where oxide stability is a concern. Harshita Stainless provides SS 439 tubing throughout Delhi and India with dependable and thermally stable piping solutions for heating and exhaust systems.

©2024 Harshita Stainless All Rights Reserved.