Stainless steel tubing is composed primarily of iron, chromium (usually 10.5% or more), and nickel, with elements like molybdenum and manganese sometimes included. Key properties include excellent corrosion resistance, high strength, and good machinability. It also offers resistance to high temperatures and oxidation. The advantages of stainless steel tubing include durability, aesthetic appeal, and low maintenance. Its resistance to rust and staining makes it ideal for harsh environments, while its strength and versatility suit applications in industries such as automotive, aerospace, and construction.

| Specifications | : | ASTM A/ASME SA213/ A249/ A269 |

| Dimensions | : | ASTM, ASME and API |

| SS 310/ 310S Tubes Size | : | 1/8″NB TO 30″NB IN |

| Schedule | : | SCH20, SCH30, SCH40, XS, STD, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Form | : | Round, Rectangular, Square, Hydraulic Etc |

| Type | : | Seamless / Fabricated / ERW / Welded / LSAW Tubes |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| AISI 904L | Maximum | Minimum |

|---|---|---|

| Ni | 28.00 | 23.00 |

| C | 0.20 | – |

| Mn | 2.00 | – |

| P | 00.045 | – |

| S | 00.035 | – |

| Si | 1.00 | – |

| Cr | 23.0 | 19.0 |

| Mo | 5.00 | 4.00 |

| N | 00.25 | 00.10 |

| CU | 2.00 | 1.00 |

| Element | Grade 904L |

|---|---|

| Density | 8 |

| Melting Range | 1300 -1390 ℃ |

| Tensile Stress | 490 |

| Yield Stress (0.2%Offset) | 220 |

| Elongation | 35% minimum |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

At Harshita Stainless, we are proud to be the largest supplier, manufacturer, and exporter of Stainless Steel 904L Tubing in Dubai, India. Our cutting-edge solutions cater to all your piping needs. With state-of-the-art production facilities strategically located in the India, we maintain a vast inventory of over 16,000 tons of premium-quality materials, ensuring we have the stock readily available to meet your demands.

With outstanding corrosion resistance, Stainless Steel 904L Seamless Tubing is ideal for high-pressure applications. Typically available in sizes ranging from 1/8″ to 8″ in diameter and custom lengths, it offers uniform strength and durability without weld seams.

Welded stainless steel tubing provides good corrosion resistance and is often used in less critical applications. Sizes generally range from 1/2″ to 12″ in diameter. Its manufacturing process involves welding a flat-rolled stainless steel sheet into a tube shape.

Stainless steel heat exchanger tubes are highly corrosion-resistant and designed for thermal conductivity. Available in various sizes, typically from 1/2″ to 4″ in diameter and up to 20 feet long. Essential for efficient heat transfer in industrial processes.

Instrumentation stainless steel tubing offers excellent corrosion resistance and is used for precise control systems. Standard sizes range from 1/16″ to 1″ in diameter. It ensures reliable performance in various high-pressure and high-temperature applications.

Boiler tubes of stainless steel are known for their exceptional corrosion and high-temperature resistance. Available in sizes from 1/2″ to 4″ in diameter. Designed for use in power generation and industrial boilers to handle high-pressure steam.

Stainless steel U-tubes provide high corrosion resistance and are used in heat exchangers and condensers. Sizes usually range from 1/2″ to 4″ in diameter. They are fabricated into a U shape to fit specific thermal or fluid flow requirements.

Condenser tubes made of stainless steel are highly corrosion-resistant and used in cooling systems. Commonly available in diameters from 1/2″ to 4″ and lengths up to 20 feet. Essential for efficient heat exchange in cooling applications.

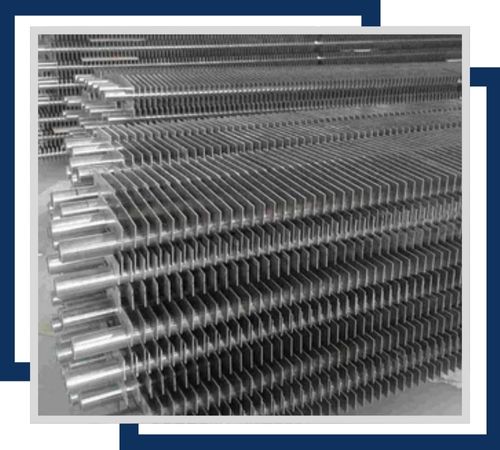

Stainless steel fin tubes offer enhanced heat transfer efficiency and corrosion resistance. Sizes range from 1/2″ to 4″ in diameter with various fin heights and thicknesses. They are used in applications with critical heat exchange efficiency, such as HVAC systems.

Harshita Stainless is a leading supplier, and stockist of high-quality stainless steel 904L tubing in Dubai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

Stainless steel 420 tubing is widely used in various industries due to its excellent durability and moderate corrosion resistance. Typical applications include the manufacture of surgical instruments, molds and dental instruments, where accuracy and durability are required. They also produce mechanical parts, such as valves, shafts and gears, which require high strength and resistance. In addition, stainless steel 420 tubing is used in automotive and aerospace products, petrochemical processing equipment and food processing machinery due to its versatility and reliability in harsh environments

©2024 Harshita Stainless All Rights Reserved.