Home > Sheet and Plates > Stainless Steel 420 Sheet and Plates

Stainless Steel 420 Sheets and Plates are renowned for their high carbon content and martensitic structure, which give them remarkable hardness, wear resistance, and a beautiful polish. These materials are perfect for situations where you need strong mechanical performance alongside decent corrosion resistance. Thanks to their ability to be hardened through heat treatment, Grade 420 is a go-to choice for cutting tools, industrial machinery, and parts that face heavy wear. With their smooth finish and impressive strength, Stainless Steel 420 sheets and plates are a dependable option for both industrial and commercial uses.

Typically, Stainless Steel 420 is made up of 12–14% chromium and 0.15–0.40% carbon, along with small amounts of manganese, silicon, phosphorus, and sulfur. This unique blend allows the steel to reach a Rockwell hardness of 50 HRC or even higher. When properly heat treated, it boasts a tensile strength of about 700–1000 MPa. While its corrosion resistance isn’t as high as that of austenitic grades like 304, it holds up well in mildly corrosive environments, such as air, water, and certain food processing conditions, especially when polished and well-maintained.

Stainless Steel Sheets and Plates Specification : ASTM A240 / ASME SA240

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 420 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 12.0 max: 14.0 | – |

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Brinell (HB) |

|---|---|---|---|---|

| Annealed * | 655 | 345 | 25 | 241 max |

| 399°F (204°C) | 1600 | 1360 | 12 | 444 |

| 600°F (316°C) | 1580 | 1365 | 14 | 444 |

| 800°F (427°C) | 1620 | 1420 | 10 | 461 |

| 1000°F (538°C) | 1305 | 1095 | 15 | 375 |

| 1099°F (593°C) | 1035 | 810 | 18 | 302 |

| 1202°F (650°C) | 895 | 680 | 20 | 262 |

Contact us to get a quick quote for your requirement.

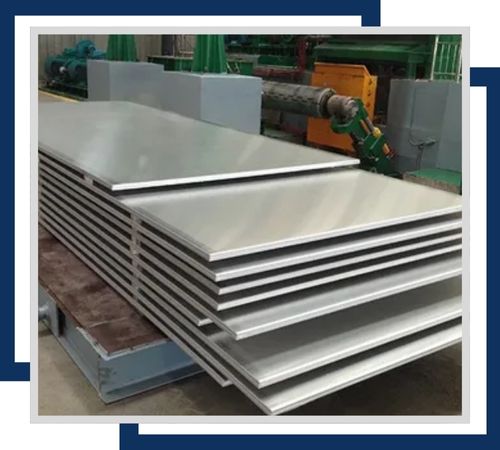

These are stainless steel 420 hot rolled sheets that can offer excellent corrosion resistance and a durability that no other material could. They range from 3mm to 12mm thickness and are most suitable for any application that calls for high strength and good machinability.

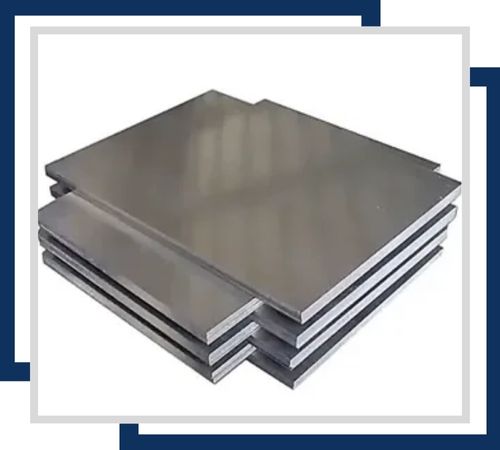

Stainless Steel 420 cold rolled plates offer excellent corrosion resistance and a bright finish. These plates are available in thicknesses ranging from 0.5mm to 6mm and are used in precision applications where dimensional accuracy and fine surface finish are critical.

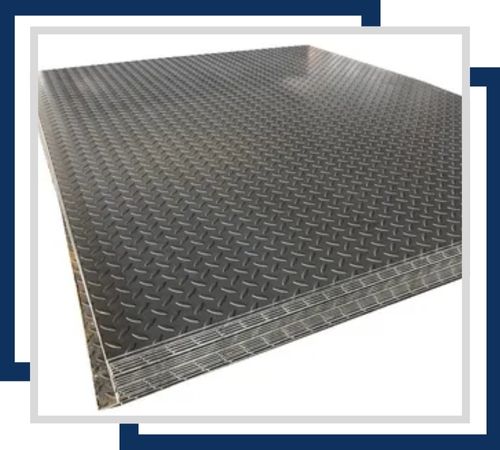

Stainless Steel 420 chequered plates combine excellent corrosion resistance with a textured surface for slip resistance. They are available in thicknesses from 2mm to 8mm and various patterns, and are widely used in flooring and safety applications.

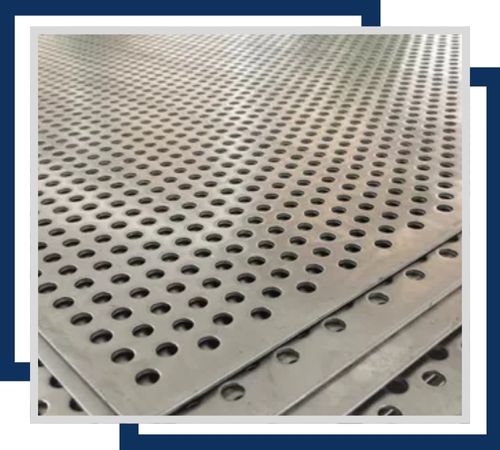

Stainless Steel 420 perforated sheets are corrosion-resistant and have uniform holes for ventilation and aesthetics. They are available in thicknesses from 1mm to 5mm and are used in filtering and architectural applications.

Stainless Steel 420 shim sheets are very corrosion resistant and precise. Generally available in the thickness of 0.1mm to 1mm, these are used for precise spacing and alignment in many engineering and manufacturing applications.

Stainless Steel 420 polished plates have excellent corrosion resistance and a reflective finish. Available in thicknesses ranging from 1mm to 10mm, they are used for decorative and high-visibility applications where aesthetic quality and resistance to oxidation are critical.

Harshita Stainless is highly concerned with the customer experience and delivers that with adequate documentation of its premium-quality Stainless Steel 420 Sheets and Plates. We deliver to our clients the necessary documents like a commercial invoice, packing list, fumigation certificate, heat treatment chart, quality assurance plan, and NABL-approved lab test report. These documents validate the genuineness and superior quality of our products and, therefore, ensure confidence in our valued customers. In addition, we provide our Stainless Steel 420 Sheets and Plates with different test certificates, including MTC according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third Party Inspection Certificate, reflecting our customer-first approach and dedication to excellence.

You’ll often find Stainless Steel 420 Sheets and Plates in applications where high hardness, abrasion resistance, and edge retention are crucial. They’re commonly used in surgical instruments, cutlery, knives, dies, valve components, pump parts, and wear-resistant liners. Additionally, they play a vital role in industrial machinery and tooling, where they frequently come into contact with hard surfaces or undergo repeated motion. Their ability to keep sharp edges and resist deformation makes them particularly valuable in manufacturing and fabrication sectors. While they’re not the best choice for environments rich in chlorides or highly corrosive conditions, they deliver excellent value and performance in general-purpose, high-strength applications.

©2024 Harshita Stainless All Rights Reserved.