A reputable producer and supplier of stainless steel 416 tubing, Harshita Stainless is situated in Delhi, India, and is well-known for its exceptional machinability and resistance to corrosion in mild conditions. SS 416 tubing, a martensitic stainless steel that offers improved mechanical properties through heat treatment, is specifically designed for applications needing strength and accuracy. Harshita Stainless offers tubing solutions that satisfy both client-specific needs and global quality standards. The company serves a variety of industries, including engineering, automotive, defence, and instrumentation, both in India and international markets, with an emphasis on consistent quality, dimensional accuracy, and timely delivery.

Chromium (12–14%), iron as the base, and sulphur (up to 0.15%) to enhance machinability make up stainless steel 416 tubing. Carbon, silicon, and manganese are examples of trace elements. It is a martensitic grade that is free-machining and heat-hardenable. In general, SS 416 tubing has an elongation of 15–25%, a yield strength of roughly 275 MPa, and a tensile strength of 550–760 MPa. It is appropriate for parts that need precision machining and moderate strength in dry or mildly corrosive environments because it offers fair toughness, excellent machinability, and moderate corrosion resistance.

| Grade | UNS | BS | BS | EN | EN | Swedish | Japanese |

| – | No. | EN | Name | SS | JIS | ||

| 416 | S41600 | 416S21 | 56AM | 1.4005 | X12CrS13 | 2380 | SUS 416 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 416 | min.max. | -0.15 | -1.25 | -1.00 | -0.060 | 0.15- | 12.0-14.0 | – | – |

| Tempering Temperature (°C) | Tensile Strength(MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

| Annealed * | 517 | 276 | 30 | 262 | – |

| Condition T ** | 758 | 586 | 18 | 248-302 | – |

| 204 | 1340 | 1050 | 11 | 388 | 20 |

| 316 | 1350 | 1060 | 12 | 388 | 22 |

| 427 | 1405 | 1110 | 11 | 401 | # |

| 538 | 1000 | 795 | 13 | 321 | # |

| 593 | 840 | 705 | 19 | 248 | 27 |

| 650 | 750 | 575 | 20 | 223 | 38 |

Contact us to get a quick quote for your requirement.

We ensures the highest quality stainless steel 416 tubing through stringent testing and certification procedures. Each tube undergoes a thorough inspection, including dimensional testing, mechanical property testing and corrosion resistance evaluation. Certificates of compliance with traceability and quality reports are provided to ensure efficiency and reliability.

Available in sizes ranging from 0.25″ to 6″ outer diameter, 416 seamless tubing offers excellent corrosion resistance and machinability. Ideal for precision applications where smooth surfaces and dimensional accuracy are critical.

With dimensions typically ranging from 0.5″ to 24″ outer diameter, 416 welded tubing is corrosion-resistant and cost-effective for larger diameter applications. It is suitable for structural and non-critical fluid transfer purposes.

Available in sizes from 0.5″ to 2″ outer diameter, these tubes provide good corrosion resistance and thermal conductivity. They are used in heat exchangers where strength and durability are essential.

Ranging from 1/8″ to 1″ outer diameter, 416 instrumentation tubing offers excellent corrosion resistance and high strength. It is used in precise control and measurement applications in various industries.

With sizes typically from 0.5″ to 5″ outer diameter, 416 boiler tubes provide excellent corrosion resistance and high-temperature performance. They are designed for use in steam boilers and other high-pressure environments.

Available in dimensions from 0.5″ to 3″ outer diameter, 416 U-tubes are corrosion-resistant and ideal for heat exchangers where compact design and efficient heat transfer are required. Their U-shape allows for easier installation in tight spaces.

Ranging from 0.5″ to 2″ outer diameter, 416 condenser tubes offer good corrosion resistance and efficient heat transfer. They are used in condensers to cool steam and other fluids in power plants and industrial applications.

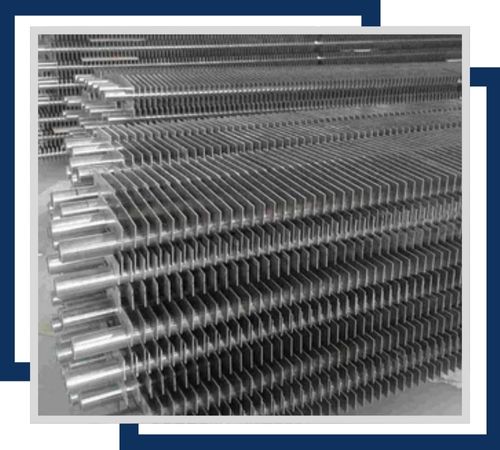

With sizes typically from 0.5″ to 3″ outer diameter, 416 fin tubes provide excellent corrosion resistance and enhanced heat transfer capabilities. They are used in heat exchangers and air coolers where maximizing surface area is critical for efficient operation.

Applications requiring high machinability and moderate corrosion resistance frequently use stainless steel 416 tubing. It is utilised in the automotive industry for gearbox parts, valve sleeves, and fuel injection components. In the engineering and manufacturing industries, it is also used in gears, shafts, pumps, and bushings. It is used for machined fasteners and structural elements in aerospace and defence. Instruments, fittings, and other precision-machined components where dependable mechanical performance and ease of machining are crucial can all benefit from the use of SS 416 tubing. However, because it has less corrosion resistance than austenitic grades, it works best in environments with mild corrosion.

©2024 Harshita Stainless All Rights Reserved.