Located in Delhi, India, Harshita Stainless is a reputable manufacturer and supplier of stainless steel 410S tubing, providing dependable and affordable solutions for applications needing good oxidation performance and moderate corrosion resistance. A low-carbon, non-hardening variation of Type 410, stainless steel 410S improves formability and weldability while preserving strength and thermal stability. For heat exchangers, exhaust systems, and other industrial applications, Harshita Stainless guarantees exact dimensional accuracy, quality control, and prompt delivery of tubing. The business provides services to both domestic and foreign markets in sectors like power generation, thermal processing, automotive, and petrochemicals.

The main component of stainless steel 410S tubing is chromium (11.5–13.5%), with a low carbon content (≤0.08%), and trace amounts of silicon, phosphorus, sulphur, and manganese. Particularly in mildly corrosive environments, this ferritic stainless steel is renowned for its strong resistance to oxidation and corrosion. Mechanically, it offers elongation of about 20%, yield strength of about 205 MPa, and tensile strength of 415–585 MPa. It is perfect for thermal applications where ductility and stability are crucial without post-weld hardening because it is highly weldable and maintains strength and scale resistance at high temperatures.

Specifications : ASTM A731, A268 / ASME SA731, SA268

Dimensions : ASTM, ASME and API

Size : 1/2″ NB to 24″ NB

Type : Seamless, Welded, EFW, ERW, Fabricated

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Form : Round Pipes, Square Pipes, Rectangular Pipes, Oval Pipes, Hydraulic Pipe, etc.

End : Plain End, Treaded, Beveled End

Length : Single Random, Double Random & Cut Length. (Custom Sizes Available as per customers requirement)

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410s | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 | 0.50 max |

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410s | 65 (450) | 30 (205) | 20 | 217 | 96 |

Contact us to get a quick quote for your requirement.

We guarantees the highest quality standards of Stainless Steel 410S Tubing through proper testing procedures. All products undergo extensive inspection processes, including mechanical and chemical testing, to meet international specifications. The company offers relevant certifications that guarantee material authenticity, performance, and compliance with industry standards for reliability and excellence.

This tubing comes in various sizes, typically ranging from 1/8″ to 12″ in diameter. It is known for its moderate corrosion resistance and is often used in applications requiring high strength and toughness.

Available in sizes from 1/4″ to 8″ in diameter, this tubing offers good corrosion resistance and is ideal for applications requiring welded joints. It’s commonly used in structural and high-stress environments.

Typically sized between 1/2″ to 2″ in diameter, this tube is designed for optimal heat transfer and corrosion resistance in heat exchangers. It is suitable for high-temperature applications.

Sizes for this tubing usually range from 1/8″ to 1″ in diameter. It is used in precision instruments and offers moderate corrosion resistance, making it suitable for various analytical and control instruments.

Available in sizes from 1″ to 6″ in diameter, these tubes are designed to withstand high temperatures and pressures in boiler systems. They provide moderate resistance to corrosion in high-heat environments.

Typically used in heat exchangers, these U-tubes come in sizes from 1/2″ to 2″ in diameter. They offer good resistance to corrosion and high durability in cyclic heating and cooling applications.

Usually sized between 1/2″ and 2″ in diameter, these tubes are used in condensers and are designed to resist corrosion and handle high thermal stress efficiently.

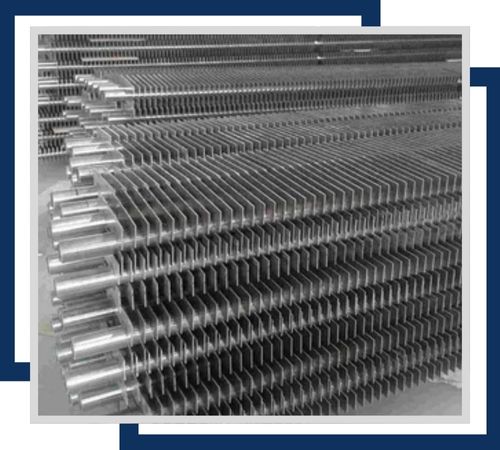

Fin tubes come in various diameters, typically from 1/2″ to 2″ with extended fins for enhanced heat transfer. They provide good resistance to corrosion and are used in heat exchangers and cooling systems.

Applications requiring moderate strength and resistance to oxidation at high temperatures frequently use stainless steel 410S tubing. It is frequently used in mufflers and exhaust systems in the automotive industry. It is used in recuperators, steam turbines, and heat exchangers in thermal processing and power plants. Additionally, annealing boxes, burners and furnace components use it. Oil refineries and petrochemical facilities that handle mildly corrosive fluids can use 410S tubing because of its good weldability and corrosion resistance. It is a dependable option for high-temperature structural tubing applications because it can tolerate thermal cycling without deforming.

©2024 Harshita Stainless All Rights Reserved.