Located in Delhi, India, Harshita Stainless is a well-known producer and supplier of stainless steel 410 bars, providing premium solutions for demanding industrial and engineering applications. Martensitic stainless steel, which is renowned for its great strength, hardness, and moderate resistance to corrosion, is used to make these bars. To satisfy the unique requirements of customers in a variety of industries, Harshita Stainless provides SS 410 bars in a range of sizes and finishes. With a strong commitment to precision manufacturing, stringent quality control, and timely delivery, the company serves sectors like automotive, aerospace, construction, and general engineering, ensuring dependable performance and long-lasting durability in critical applications.

In addition to trace amounts of manganese, silicon, and nickel, the main constituents of stainless steel 410 bars are chromium (11.5–13.5%), carbon (0.08–0.15%), and iron. Heat treatment can harden this martensitic stainless steel, giving it a high mechanical strength. It has an approximate yield strength of 250–400 MPa, a tensile strength of 450–750 MPa, and an elongation of 20–25%. Additionally, SS 410 offers good wear resistance and moderate corrosion resistance. Because of these characteristics, it is perfect for parts that are exposed to wear, mechanical stress, and mildly corrosive conditions.

| Specification | ASTM A479/ SA479 ASTM A276/ ASME SA276 |

|---|---|

| Grade | Stainless Steel 410 (UNS S41000) |

| Hex Bar size | 18 to 57mm (11/16″ – 2-3/4″) |

| Round bar size | OD 4mm to 500mm |

| Square bar size | 18mm to 47mm (11/16″- 1-3/4″) |

| Billet Size | 1/2″- 495mm Dia. |

| Rectangles Size | 33 x 30mm – 295 x 1066mm |

| Bright Bar | OD 4mm to 100mm |

| Tolerance | K12 H12, K10, H9, H11, H8, H13K9, H10, K11, or as per need |

| Flat bar size | 1/2” to 10” in thickness of 2 to 150mm |

| Angle bar size | 3*20*20~12*100*100 |

| Finish | centreless ground, Cold (bright) drawn, hot rolled, peeled, smooth turned, hot rolled annealed, slit rolled edge, Bright, Rough Turned, Grinding, Polish & Black |

| Form | Flat Bar, Hollow, Round, Square, Triangle, Rectangle, Half Round Bar, Rod, T-Bar, Precision Ground Bar, Hex (A/F), Blocks, Channel Bar, Threaded, Round Rod, Billet, Profiles, I/H Bar, Ingot, Rings, Forging etc. |

| Technique | 440C Stainless Steel Hot Rolled, Cold Drawn, Rod, Forged Round Bar, Cold Rolled |

| Condition | annealed, Hardened & tempered |

| Section | 3.0 -12.0 mm thickness, 80 x 40 to 150 x 75mm section |

| Channel Bar | 5.0 – 6.0mm thickness |

| Surface | Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Polished, Hairline |

| Hollow Bar | 32mm OD x 16mm ID – 250mm OD x 200mm ID |

| Grade | AISI | Stainless Steel Bolts & Nuts Chemical Composition (% maxima unless stated) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu | ||||||

| 410 | SS 410 | 0.09-0.15 | 1.0 | 1.0 | 0.05 | 0.03 | 11,5 – 14,0 | – | 1 | – | ||||

| Type | Tensile Strength | Yield Strength (0.2% offset) | Elongation in 2” (50.80mm) % | Hardness (Rockwell) | ||

|---|---|---|---|---|---|---|

| Ksi | MPa | Ksi | MPa | |||

| 410 | 70 | 483 | 45 | 310 | 25 | B80 |

Contact us to get a quick quote for your requirement.

We ensures that all 410 stainless steel panels are rigorously tested for quality, strength and durability. Each product is certified to appropriate industry standards, including mechanical components, corrosion resistance and finishes. These certifications assure reliable performance and compliance with global quality standards in industrial applications.

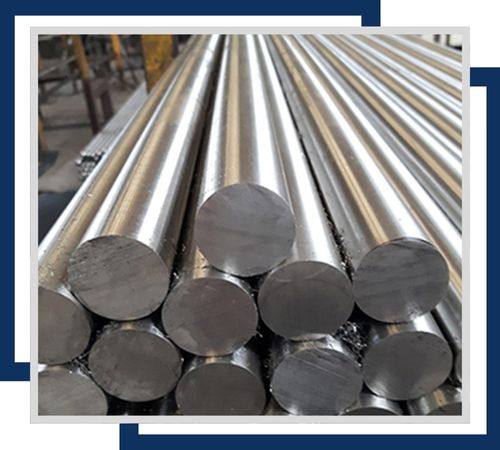

Corrosion-resistant and heat-treatable, Stainless Steel 410 Round Bars are available in diameters from 0.5″ to 12″. They are ideal for applications in cutlery, automotive parts, and industrial components requiring high hardness and moderate corrosion resistance.

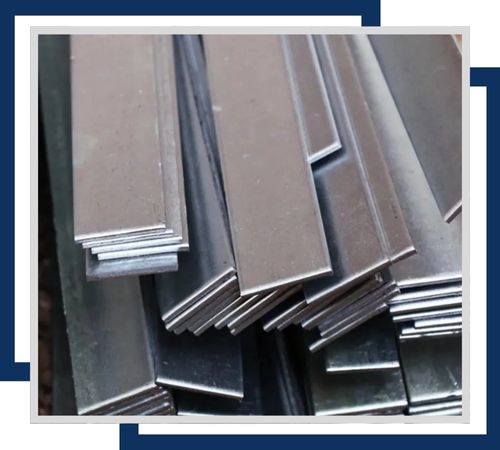

Stainless Steel 410 Flat Bars offer high strength and good machinability, with thicknesses from 0.25″ to 6″ and widths up to 12″. Suitable for manufacturing tools, hardware, and parts that need durability and wear resistance.

Corrosion-resistant Stainless Steel 410 Square Bars are available in sizes from 0.5″ to 6″ on each side. They are used in applications requiring high hardness and resistance to wear, such as in industrial machinery and components.

Stainless Steel 410 Rectangular Bars provide high strength and corrosion resistance, available in sizes from 0.5″ x 1″ to 6″ x 12″. Ideal for heavy-duty applications, including parts and tools that need excellent durability and wear resistance.

Offering good corrosion resistance and machinability, Stainless Steel 410 Hexagonal Bars come in sizes from 0.5″ to 4″ across flats. Suitable for use in hardware, machinery, and parts that require strength and durability.

Corrosion-resistant Stainless Steel 410 T-Bars are available in dimensions from 0.5″ x 0.5″ to 6″ x 6″. They are ideal for structural and industrial applications where high hardness and wear resistance are needed.

Numerous industries that require high strength, durability, and wear resistance use stainless steel 410 bars. They are used in bushings, fasteners, and shafts in the automotive industry. They are used in the defence and aerospace industries for parts that need to be dimensionally stable and long-lasting. SS 410 bars are utilised for decorative fittings and structural supports in architecture and construction. Additionally, they are perfect for producing machine parts, valves, pump parts, and surgical instruments. They are appropriate for use in general-purpose engineering tasks and mild chemical environments due to their resistance to moderate corrosion and mechanical wear.

©2024 Harshita Stainless All Rights Reserved.