Based in Delhi, India, Harshita Stainless is a reputable producer and supplier of stainless steel 405 tubing, offering reasonably priced, superior solutions for structural and thermal applications. Stainless Steel 405, a ferritic stainless steel developed for enhanced weldability and performance in mildly corrosive environments, is well-known for its good oxidation resistance and ease of fabrication. In order to ensure adherence to industry standards, Harshita Stainless provides precision-manufactured tubing in a range of sizes and finishes. Serving the automotive, power generation, heat exchanger, and process industries, the company offers dependable and long-lasting tubing solutions supported by timely service and technical assistance.

In order to improve oxidation resistance and avoid hardening during welding, stainless steel 405 tubing is primarily composed of chromium (11.5–14.5%), with trace amounts of carbon (≤0.08%), silicon, manganese, and aluminium. This stainless steel is ferritic, non-hardenable, and has a moderate resistance to corrosion. In terms of mechanical properties, SS 405, it has a tensile strength of roughly 450–600 MPa, a yield strength of roughly 200–300 MPa, and an elongation of roughly 20%. It is perfect for applications involving moderate mechanical and thermal stress and maintains good ductility and toughness, particularly when annealed.

| Description | ASTM A240 / ASME SA240 Stainless Steel Plates, ASTM A240 Hot Rolled Stainless Steel Plates |

| Standard | ASTM, ASME, BS, DIN, EN |

| Material | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, |

| 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc | |

| Specification | Cold rolled: 1219mm * 2438mm (4′ x 8′), 1219mm * 3048mm (4′ x 10′), 1220mm * 2440mm, 1250mm * 2500mm or as your requirement.

Hot rolled: 1500mm * 2000mm, 1000mm * 3000mm, 1500mm * 4000mm, 1500m * 6000mm or as your requiremnt. |

| Technique | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Etc. |

| Surface | 2B, 2D, BA, NO. 1, NO. 4, NO.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Thickness | 0.25-200mm, 0.3mm to 120mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm |

| Package | Standard Export Seaworthy Package, or as required. |

| Value Added Services | Cladding,Heat Treatment,Annealed, Pickling, Polish,Rolling,Cutting,Bending,Forging,Minor Fabrication Etc. |

| MTC | Mill Test Certificate, Available as per EN 10204 3.1 |

| Element | Content (%) |

|---|---|

| Iron, Fe | 85 |

| Chromium, Cr | 13 |

| Manganese, Mn | 1.0 |

| Silicon, Si | 1.0 |

| Aluminum, Al | 0.2 |

| Carbon, C | 0.080 |

| Phosphorous, P | 0.040 |

| Sulfur, S | 0.030 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 448 MPa | 65000 psi |

| Yield strength (@strain 0.200 %/) | 276 MPa | 40000 psi |

| Elastic modulus | 200 GPa | 29007 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.00% | 25.00% |

| Izod Impact (@20°C/68°F) | 41.0 J | 30.2 ft-lb |

| Hardness, Brinell (converted from Rockwell B hardness) | 131 | 131 |

| Hardness, Knoop (converted from Rockwell B hardness) | 146 | 146 |

| Hardness, Rockwell B | 75 | 75 |

| Hardness, Vickers (converted from Rockwell B hardness) | 140 | 140 |

Contact us to get a quick quote for your requirement.

We provides high-quality Stainless Steel 405 Tubing, strength tested, durable, and precise. All our products have undergone thorough testing in their chemical composition analysis, mechanical property assessments, and dimensional checks to provide optimal performance. All products are accompanied by certifications of compliance with industry standards and customer specifications.

Manufactured without welding, this tubing offers superior structural integrity and reliability. Commonly available in sizes ranging from 1/8″ to 2″ in diameter. It has moderate corrosion resistance suitable for many applications.

Produced by welding a flat steel strip into a tubular shape, this type is typically available in sizes from 1/4″ to 6″ in diameter. It has good resistance to oxidation and is used where cost-efficiency is essential.

Designed specifically for heat exchanger applications, these tubes are available in diameters from 1/2″ to 2″. They provide good resistance to scaling and oxidation at high temperatures.

Precision-made for instrumentation purposes, this tubing usually comes in sizes from 1/16″ to 1″ in diameter. It offers excellent resistance to corrosion and is ideal for high-pressure applications.

Ideal for boiler systems, these tubes are typically found in sizes from 1″ to 3″ in diameter. They are designed to handle high temperatures and pressures, with good resistance to corrosion.

These U-shaped tubes are commonly used in heat exchangers and condensers. Sizes usually range from 1/2″ to 2″ in diameter. They provide good resistance to heat and corrosion.

Used in condenser units, these tubes are generally available in diameters from 1/2″ to 2″. They offer excellent resistance to corrosion and high temperatures, making them suitable for various thermal applications.

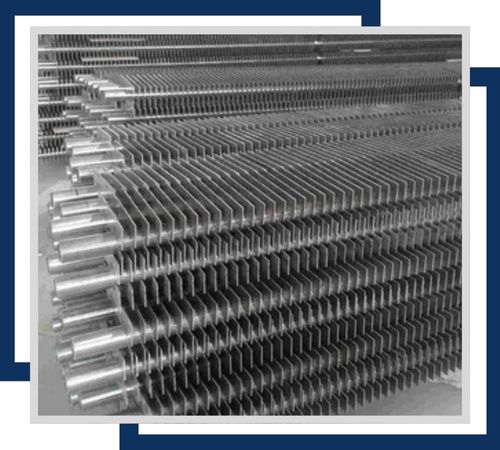

These tubes feature fins attached to increase surface area for heat transfer. They are typically available in diameters from 1/2″ to 2″. They offer good corrosion resistance and are used in heat exchangers and radiators.

Applications requiring moderate corrosion resistance and thermal stability frequently use stainless steel 405 tubing. Because of its resistance to oxidation at high temperatures, it is utilised in exhaust systems, mufflers, and manifolds in the automotive industry. Additionally, it can be used in power plant components, steam lines, and heat exchangers. It is used in process piping and ductwork for gas and air handling systems in industrial settings. Its weldability and resistance to scaling make it ideal for furnaces and kiln components. For structural and thermal service in moderately aggressive environments, SS 405 tubing is an affordable choice.

©2024 Harshita Stainless All Rights Reserved.