Harshita Stainless stands out as a top manufacturer and supplier of Stainless Steel 405 Bars, proudly based in Delhi, India. The company is recognized for providing exceptional stainless steel solutions across various industries. With a focus on high-temperature and oxidation-resistant alloys, Harshita Stainless offers precision-engineered SS 405 bars that adhere to strict quality standards. Their cutting-edge manufacturing facilities and dedication to innovation guarantee reliable product performance, precise dimensions, and prompt delivery. Whether for industrial, structural, or mechanical uses, they provide tailored sizes and finishes to meet the unique needs of clients, both locally and globally.

Stainless Steel 405 bars are made up of 11.5–14.5% chromium, along with a small amount of aluminum (around 0.2%) to enhance oxidation resistance and prevent grain coarsening during welding. With a low carbon content (≤0.08%), these bars are easy to weld. They have a ferritic structure and are magnetic. In terms of mechanical properties, they boast a tensile strength of about 450 MPa, a yield strength of roughly 205 MPa, and a Brinell hardness ranging from 150 to 200 HB. SS 405 bars offer good ductility, moderate corrosion resistance, and are ideal for forming and machining in high-temperature environments.

C | Cr | Fe | Mn | Si | S | P | Ni | Al | |

405 | 0.08 max | min: 11.5 max: 14.5 | balance | 1.0 max | 1.0 max | 0.03 max | 0.04 max | 0.50 max | min: 0.1 max: 0.3 |

Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

405 | 60 (415) | 25 (170) | 20 | 179 | 88 |

Contact us to get a quick quote for your requirement.

At Harshita Stainless, all our Stainless Steel 405 Bars go through a highly rigorous testing procedure to ensure excellent quality and performance. Our products are certified in regard to excellent corrosion resistance, high durability, and reliability. We ensure comprehensive certifications like chemical composition and mechanical properties for our superior quality to reach our customers’ doorstep.

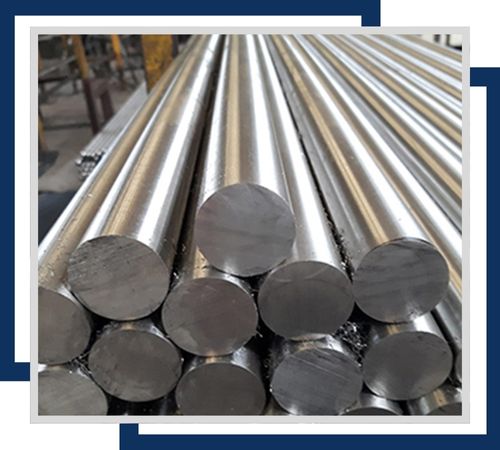

Corrosion-resistant and offering good machinability, Stainless Steel 405 Round Bars are available in diameters from 0.5″ to 12″. They are well-suited for automotive exhaust systems and industrial applications where moderate corrosion resistance and thermal stability are required.

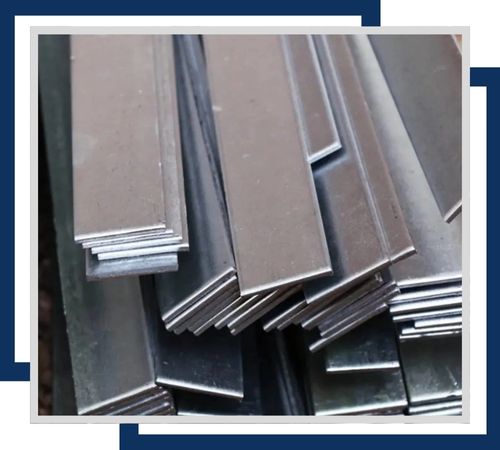

Stainless Steel 405 Flat Bars provide excellent oxidation resistance and are available in thicknesses from 0.25″ to 6″ and widths up to 12″. Ideal for structural components and machinery needing moderate corrosion resistance and high-temperature durability.

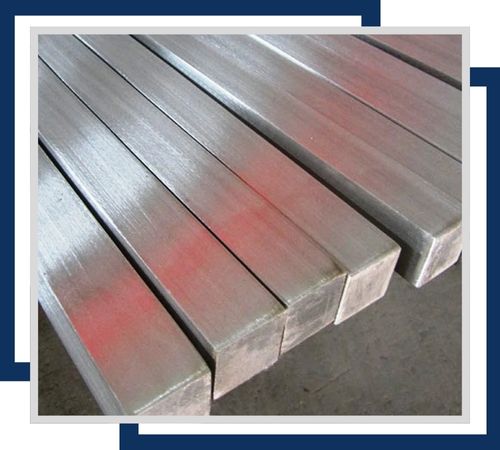

Corrosion-resistant and designed for high performance, Stainless Steel 405 Square Bars come in sizes from 0.5″ to 6″ on each side. These bars are suitable for applications requiring durability and resistance to scaling under elevated temperatures.

With Stainless Steel 405 Rectangular Bars, you get corrosion resistance and stability, available in sizes from 0.5″ x 1″ to 6″ x 12″. They are perfect for heavy-duty applications where strength and moderate oxidation resistance are essential.

Stainless Steel 405 Hexagonal Bars offer good resistance to high temperatures, available in sizes from 0.5″ to 4″ across flats. They are suitable for use in automotive parts and industrial equipment where moderate corrosion resistance is needed.

Corrosion-resistant Stainless Steel 405 T-Bars come in dimensions from 0.5″ x 0.5″ to 6″ x 6″. Ideal for structural applications and components requiring moderate oxidation resistance and high-temperature durability.

Stainless Steel 405 bars find extensive use in applications that demand good oxidation resistance, thermal stability, and moderate corrosion resistance. They are commonly found in components for heat exchangers, furnaces, and combustion chambers. Additionally, these bars are used in turbine housings, petrochemical equipment, and automotive exhaust systems, thanks to their high-temperature performance and dimensional stability. SS 405 bars are also well-suited for structural components in the chemical processing and refining industries, where weldability is crucial.

©2024 Harshita Stainless All Rights Reserved.