Based in Delhi, India, Harshita Stainless is a reputable producer and supplier of 348H stainless steel tubing, providing premium tubing solutions for applications requiring high pressure and temperatures. Stainless Steel 348H is a stabilised austenitic stainless steel that is specifically made for improved creep and stress rupture resistance, making it perfect for use in harsh environments. Serving sectors like chemical processing, heat exchangers, power plants, and aerospace, Harshita Stainless guarantees that all tubing is produced in accordance with exact measurements and international quality standards. The company provides dependable and durable tubing solutions with a strong commitment to quality, on-time delivery, and customer satisfaction.

In addition to tantalum, which stabilises the alloy against carbide precipitation, stainless steel 348H tubing contains chromium (17–20%), nickel (9–13%), and columbium (niobium). Additionally, it has more carbon (0.04–0.10%) than regular grades, which increases strength at higher temperatures. In terms of mechanical properties, it provides a tensile strength of roughly 515 MPa, a yield strength of roughly 205 MPa, and an elongation of 30–40%. 348H is appropriate for demanding thermal and structural applications because it maintains its mechanical qualities at high temperatures, shows outstanding resistance to intergranular corrosion, and has good weldability and formability.

| Sizes: | 1/8″ to 24″ |

| ASTM A312 Steel grades: | TP304/304L/304H |

| ASTM A312 Schedules: | STD, XS, XXS, SCH5S, SCH10/10S, SCH20, SCH30, SCH40/40S, SCH60, SCH80/80S, SCH100, SCH120, SCH140, SCH160 |

| Standards: | ASTM A312, ASME SA312 |

| Lengths: | SRL and DRL 5meters up to 11meters available from Stock or Production. |

| Ends: | Plain/Bevelled |

| AISI 348H Chemical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Cr | Ni | Cb | Co | Ta |

| 0.08 Max | 2.00 Max | 0.045 Max | 0.030 Max | 1.00 Max | 17.0-20.0 | 9.0-13.0 | 1.10 Max | 0.20 Max | 0.10 Max |

| Yeild strength | Tensile strength | Elongation | Reduction |

| Min 0.2% Mpa | Min Mpa | Min % | Min % |

| 205 | 515 | 30 | 50 |

Contact us to get a quick quote for your requirement.

We maintains the maximum quality levels by conducting a serious testing and testing certification process to ensure Stainless Steel 348H Tubing quality. Each of the products, before they reach the customers’ doorstep, will undergo proper tests including dimensional verification, chemical analysis, and some mechanical testing procedures. The respective company issues an MTR ensuring the material conformity to international norms and specifications.

This tubing is seamless, available in various sizes with precise dimensions. It offers excellent corrosion resistance suitable for high-temperature applications.

Welded for structural integrity, available in a range of sizes. Known for its robust construction and corrosion resistance, ideal for industrial applications.

Designed specifically for heat transfer applications, available in customized sizes. Offers superior resistance to corrosion and thermal stress.

Precision tubing with controlled dimensions for instrumentation and control systems. Provides high corrosion resistance and reliability in sensitive environments.

Engineered for high-pressure boiler systems, available in standard and custom sizes. Resistant to corrosion and oxidation, ensuring long-term performance.

U-shaped tubes used in heat exchangers and condensers, available in diverse dimensions. Offers excellent resistance to corrosion and stress cracking.

Specifically designed for condenser applications, available in various diameters. Provides superior corrosion resistance and heat transfer efficiency.

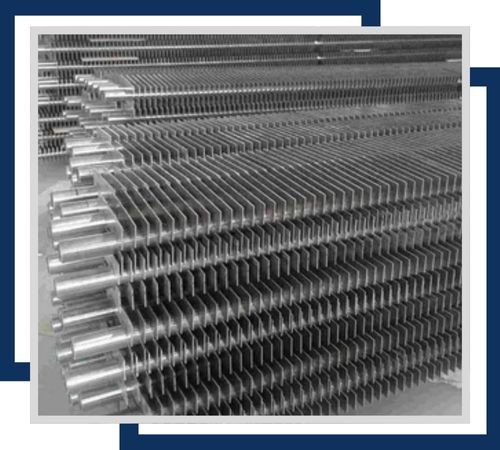

Tubes with extended surface area for enhanced heat transfer efficiency, available in multiple configurations. Offers exceptional resistance to corrosion and oxidation.

In high-temperature and high-stress settings where resistance to oxidation, creep, and intergranular corrosion is crucial, stainless steel 348H tubing is frequently utilised. Boiler tubes, heat exchangers, and superheater components all use it in power generation. It is utilised in the petrochemical and chemical industries for heaters, piping systems, and reactors that come into contact with hot, corrosive fluids. It is used in structural tubing and exhaust ducts in the aerospace industry. Additionally, it can be used in steam systems, refineries, and thermal processing equipment. 348H tubing is a dependable option for long-term critical service applications because of its resilience and ability to function in harsh environments.

©2024 Harshita Stainless All Rights Reserved.