Stainless Steel 347H Tubing is a high-carbon, columbium-stabilized austenitic stainless steel that’s built for top-notch performance in high-temperature settings. Thanks to its higher carbon content, 347H boasts impressive creep strength, making it perfect for use in hot environments like heat exchangers, boilers, and petrochemical processing systems. The inclusion of columbium (or niobium) plays a crucial role in preventing carbide precipitation during welding and thermal cycling, which helps it resist intergranular corrosion exceptionally well. SS 347H tubing merges strong mechanical properties with solid oxidation resistance, ensuring it can handle continuous heat and pressure without a hitch.

When it comes to its chemical makeup, Stainless Steel 347H features 17–20% chromium, 9–13% nickel, and a carbon content that ranges from 0.04–0.10%. It also includes stabilizing elements like columbium and tantalum to enhance thermal stability. This tubing offers a tensile strength of about 515 MPa, a yield strength of around 205 MPa, and good elongation for ductility. Its high-temperature strength and resistance to stress rupture make it a great fit for demanding structural and pressure-based applications. Plus, SS 347H maintains excellent weldability and formability, even after being subjected to intense heat.

| Specifications | ASTM A/ASME SA213/A249/A269/A312/A358 |

| Dimensions | ASTM, ASME, and API |

| Size | 1/8″NB TO 30″NB IN |

| 304 Pipes & Tubes Size | 1/2″ NB – 16″ NB |

| ERW 304 Pipes & Tubes | 1/2″ NB – 24″ NB |

| EFW 304 Pipes & Tubes | 6″ NB – 100″ NB |

| Thickness | 0.3mm – 50 mm |

| Specialized in | Large Diameter Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round, Square, Rectangular, Hydraulic, Oval, U Shape, Pan Cake Coils, Coiled Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded |

| Stainless Steel | Nickel | Magnesium | Silicon | sulfur | Carbon | Chromium | Phosphorus | Molybdenum | Nitrogen | |

| 347H | Minimum | 9 | 00.04 | 17 | 3 | |||||

| Maximum | 13 | 2 | 1 | 00.030 | 00.10 | 19 | 00.045 | 4 | ||

| SS Grade | Tensile Strength | Yield Strength | Elongation | Hardness | |

| Rockwell B | Brinell | ||||

| SS 347H | 515 | 205 | 40 | 92 | 201 |

Contact us to get a quick quote for your requirement.

We offers highest quality in its Stainless Steel 347H Tubing with severe testing and certification. Each product is thoroughly checked for dimensional measurements, mechanical tests, and corrosion resistance. Full certification including MTCs will be provided by us for your assurance that all the international standards and requirements are met.

This tubing comes in various sizes, typically ranging from 1/8″ to 12″ in diameter. It offers high resistance to oxidation and corrosion, particularly in high-temperature environments. Ideal for applications requiring robust strength and durability.

Available in diameters from 1/2″ to 12″, this tubing is welded and offers similar high-temperature strength as seamless options. It is highly resistant to intergranular corrosion and is used in environments exposed to sulfuric and nitric acids.

These tubes are generally available in sizes from 1/4″ to 2″ OD. They are specifically designed for high-efficiency heat transfer and offer excellent resistance to oxidation and sulfidation. Suitable for use in high-temperature heat exchangers.

Instrumentation tubing sizes typically range from 1/16″ to 1″. It is designed for precise and reliable measurements in harsh environments, providing excellent resistance to corrosion and high temperatures.

Available in diameters from 1/2″ to 5″, these tubes are designed to withstand high pressures and temperatures in boilers. They offer strong resistance to oxidation and carburization, making them ideal for high-temperature steam applications.

These tubes are usually sized from 1/2″ to 3″ in diameter and are formed into a U-shape for use in heat exchangers and other applications. They provide high resistance to corrosion and high-temperature deformation.

Condenser tubes come in sizes from 1/2″ to 3″ OD. They are designed for efficient heat transfer and resist corrosion from various coolants and environmental conditions, ensuring longevity in condenser systems.

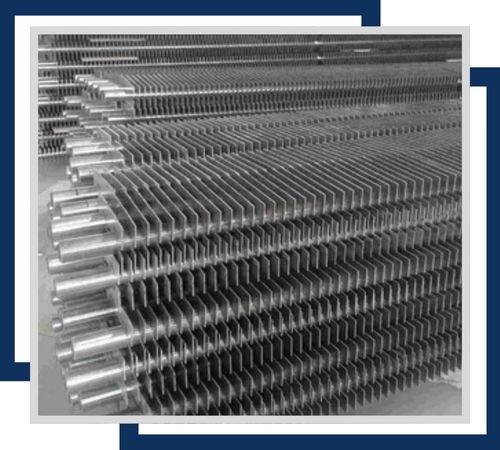

Typically ranging from 1/2″ to 3″ OD, these tubes are fitted with fins to enhance heat transfer efficiency. They offer high resistance to oxidation and corrosion, making them suitable for use in heat exchangers and cooling systems.

You’ll find Stainless Steel 347H Tubing in various industries, including power generation, aerospace, chemical processing, refineries, and thermal plants. It’s commonly used for furnace tubes, superheaters, reformer tubes, exhaust systems, and high-temperature steam lines. The alloy’s ability to resist oxidation, creep, and thermal fatigue makes it particularly valuable in environments that experience cyclic heating and prolonged heat exposure. With 347H tubing, you can count on long-term durability and operational safety in systems that require reliable performance under extreme thermal and mechanical stress.

©2024 Harshita Stainless All Rights Reserved.