Harshita Stainless, located in Delhi, India, is a reputable manufacturer and supplier of high-quality Stainless Steel 347 Tubing, designed specifically for high-temperature and corrosive environments. SS 347 is a niobium-stabilized austenitic stainless steel that excels in resisting intergranular corrosion and performs exceptionally well during welding and thermal cycling. Harshita Stainless offers tubing in a variety of sizes, thicknesses, and finishes, all customized to meet both national and international standards. With a strong commitment to quality, customization, and prompt delivery, the company caters to industries such as chemical processing, power generation, aerospace, and oil & gas, both in India and around the globe.

Stainless Steel 347 tubing consists of 17–20% chromium, 9–13% nickel, and niobium (columbium), which stabilizes the alloy and helps prevent carbide precipitation during welding. It boasts impressive mechanical properties, with a tensile strength of about 515 MPa, yield strength near 205 MPa, and Brinell hardness between 150–200 HB. SS 347 maintains its structural integrity at elevated temperatures up to 870°C and offers excellent resistance to creep and stress rupture. The tubing is non-magnetic in its annealed state and showcases outstanding weldability, oxidation resistance, and protection against intergranular corrosion.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 304H Tubes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 20.00 | 10xC – 1.10 | 9.00 – 13.00 | 62.74 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We sets high standards regarding quality for stainless steel 347 tubing through multiple testing and evaluation procedures. Inspections are extensive and include determination of chemical compositions, mechanical testing, and testing by non-destruction methods on every product. Shashank also offers full documentation in the form of Mill Test Certification.

Offering excellent corrosion resistance, Stainless Steel 347 Seamless Tubing is known for its uniformity and strength. It typically comes in sizes ranging from 6mm to 350mm in diameter and lengths of up to 6 meters. Ideal for applications requiring high pressure and corrosive resistance.

Stainless Steel 347 Welded Tubing provides superior resistance to chloride-induced stress corrosion cracking. Available in sizes from 10mm to 150mm in diameter and standard lengths of 6 meters. It is often used in industrial and chemical processing applications where weld strength is critical.

Featuring outstanding corrosion resistance, Stainless Steel 347 Heat Exchanger Tubes are used in demanding environments. Sizes typically range from 6mm to 50mm in diameter, with wall thickness varying from 1mm to 3mm. These tubes are designed for high temperature and pressure conditions.

Stainless Steel 347 Instrumentation Tubing offers excellent resistance to corrosion and is ideal for precise measurement systems. Common sizes include 1/8″ to 1/2″ in diameter and lengths up to 6 meters. It is suitable for high-pressure applications and harsh environments.

With superior resistance to both oxidation and corrosion, Stainless Steel 347 Boiler Tubes are used in high-pressure steam applications. Sizes typically range from 25mm to 100mm in diameter, with lengths of up to 6 meters. They are essential for maintaining efficiency in boiler systems.

Stainless Steel 347 U-tubes provide excellent resistance to corrosive fluids and are commonly used in heat exchangers. Standard sizes range from 10mm to 100mm in diameter with various lengths. They are designed to handle thermal expansion and contraction in dynamic environments.

Stainless Steel 347 Condenser Tubes are used in marine and power generation applications, offering exceptional resistance to seawater and acidic environments. Sizes typically range from 10mm to 50mm in diameter and lengths up to 6 meters, providing durability and efficiency.

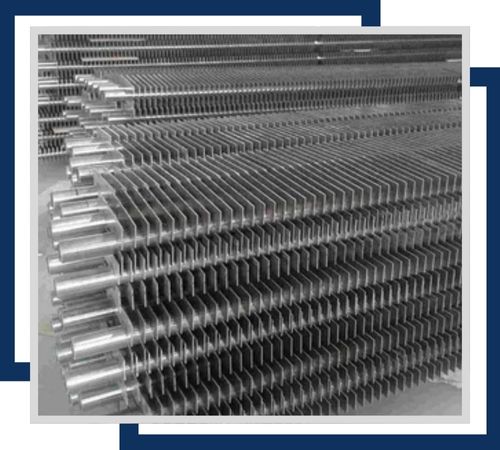

Stainless Steel 347 Fin Tubes are designed for enhanced heat transfer and corrosion resistance in air-cooled heat exchangers. They are available in various diameters, commonly 25mm to 50mm, with fin lengths customizable to specific requirements, ensuring effective cooling in challenging environments.

Stainless Steel 347 tubing is perfect for applications that involve high temperatures, pressure, and corrosive environments. It’s commonly found in heat exchangers, superheaters, and boiler tubes within power plants and chemical processing facilities. The aerospace industry also utilizes this tubing, especially in aircraft exhaust systems and engine components. In refineries and petrochemical sectors, SS 347 tubing is essential for transporting high-temperature fluids and gases, thanks to its impressive resistance to intergranular corrosion.

©2024 Harshita Stainless All Rights Reserved.