Premium-grade stainless steel 347 bars from Delhi, India-based Harshita Stainless, a well-known manufacturer and supplier, are made to perform exceptionally well in corrosive and high-temperature conditions. These bars are well-known for their superior mechanical qualities and exceptional resistance to intergranular corrosion, making them perfect for use in structural, chemical, and thermal processing applications. Harshita Stainless guarantees meticulous adherence to international quality standards, accurate finishing, and customised sizing to satisfy particular customer requirements. The business provides dependable and long-lasting solutions to a variety of industries, including petrochemicals, power generation, oil and gas, and aerospace, thanks to its sophisticated manufacturing capabilities and committed customer service.

347 Stainless Steel Chromium (17–20%), nickel (9–13%), and niobium (columbium), which stabilises the alloy against carbide precipitation during welding and high-temperature exposure, make up bars. Silicon, manganese, and carbon are other elements. These bars have an elongation of 35–40%, a yield strength of 205 MPa, and a tensile strength of roughly 515 MPa. They have good formability, high-temperature stability, and outstanding creep strength. Stainless Steel 347 ensures strength and structural integrity over time and is especially well-suited for settings that experience frequent thermal cycling and exposure to highly oxidising conditions.

| Specifications | ASTM A276 / ASME SA276 |

| Dimensions | ASTM, ASME |

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Length |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

|

Grade |

Mn |

N |

P |

C |

S |

Cr |

Mo |

Si |

Ni |

Other |

|

|

347 |

min. max |

2.00 |

– |

0.045 |

– 0.08 |

0.030 |

17.0 19.0 |

– |

0.75 |

9.0 13.0 |

Nb=10(C+N) 1.0 |

Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

Rockwell B (HR B) max | Brinell (HB) max | ||||

347 | 515 | 205 | 40 | 92 | 201 |

Contact us to get a quick quote for your requirement.

We ensures that all stainless steel 347 frames are rigorously tested for quality and performance. Our products are tested for technical properties, corrosion resistance and durability. We assure customers of high industry standards and compliance, offering comprehensive certifications including Mill Test Certificates (MTC) and third-party inspections.

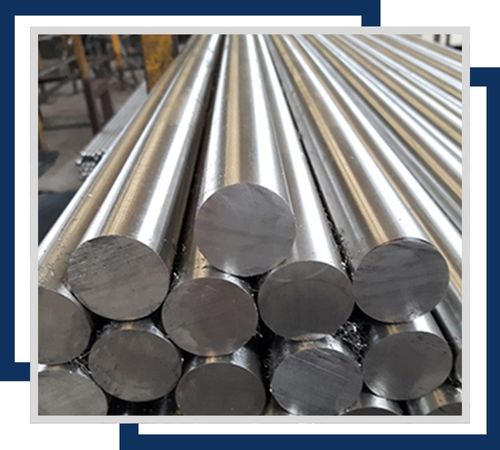

Corrosion-resistant product with high-temperature stability, available in diameters ranging from 0.5″ to 12″. Ideal for use in aerospace, chemical processing, and power generation industries where durability is essential.

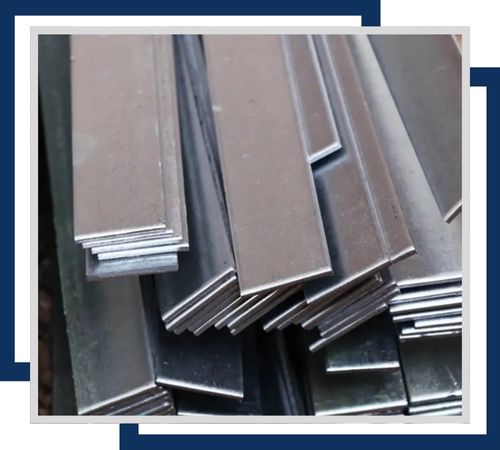

This product features exceptional resistance to oxidation, available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural components and industrial applications.

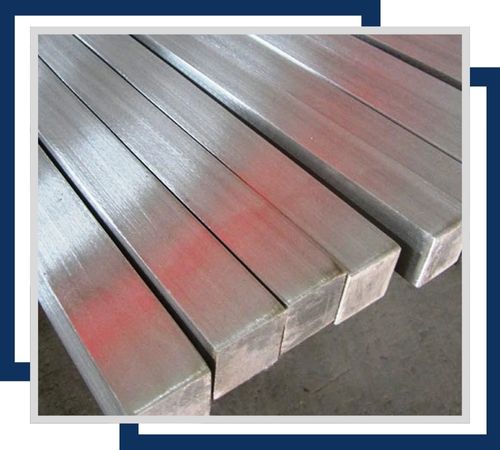

Stainless Steel 347 Square Bars are Corrosion-resistant product designed for durability, offered in sizes from 0.5″ to 6″ on each side. Suitable for use in high-temperature environments and demanding industrial applications.

This Corrosion-resistant product with dimensions ranging from 0.5″ x 1″ to 6″ x 12″. Ideal for heavy-duty applications where strength and resistance to harsh conditions are required.

Stainless Steel 347 Hexagonal Bars are Corrosion-resistant product with sizes from 0.5″ to 4″ across flats. Used in aerospace and chemical industries, offering high performance in extreme environments.

Stainless Steel 347 T-Bars dimensions from 0.5″ x 0.5″ to 6″ x 6″. Suitable for structural support and applications requiring high-temperature resistance and reliability.

Applications needing high strength and corrosion and heat resistance frequently use stainless steel 347 bars. They are used in heat exchangers, piping systems, and reactor vessels in the chemical and petrochemical industries. Because they are resistant to thermal fatigue, power plants use them in exhaust systems, boiler tubes, and superheater components. 347 bars are used in the marine and aerospace industries for high-temperature-exposed structural assemblies and engine parts. They are also appropriate for use in refineries, pharmaceutical companies, and food processing. They are perfect for use in corrosive, high-pressure, and high-temperature environments because of their stability, weldability, and durability.

©2024 Harshita Stainless All Rights Reserved.