Stainless Steel 321H is a titanium-stabilized austenitic stainless steel alloy that features a higher carbon content (0.04–0.10%) compared to standard 321, which boosts its creep resistance. Its makeup includes 17–19% chromium, 9–12% nickel, and up to 0.7% titanium. 321H pipes showcase impressive mechanical properties, boasting a tensile strength of 515–620 MPa, yield strength of 205–275 MPa, and an elongation of 40–50%. This alloy retains its strength and resists intergranular corrosion even at elevated temperatures, making it ideal for welded and high-heat applications.

| ASTM Specification | ASME SA 312 /ASTM A312/ TP 321H |

| EFW Pipes Sizes |

|

| Wall THK | Schedule 40, Schedule 5, Schedule10, Schedule 160, Schedule 80, Schedule XXS, Schedule 80S, Schedule XS |

| Seamless Pipes Sizes |

|

| Welded Pipes Sizes |

|

| Forms | ERW / Round, Rectangular |

| techniques | EFW/ Welded /ERW / Seamless / Fabricated / LSAW/ CDW/ Seam-Welded / Redrawn |

| Element | SS 321H |

| Nickel | 09 To 12 |

| sulfur | 00.03 Maximum |

| Nitrogen | 00.10 |

| Chromium | 17 To 19 |

| Silicon | 00.75 Maximum |

| Magnesium | 2 Maximum |

| Carbon | 00.04 To 0.08 |

| Phosphorus | 00.045 Maximum |

| Titanium | 00.70 Maximum |

| Element | SS 321H |

| Tensile Strength | 515 |

| Yield Strength | 205 |

| Elongation | 40 |

| Rockwell | 95 |

| Brinell | 217 |

Contact us to get a quick quote for your requirement.

At Harshita Stainless, we are proud to be the largest supplier, manufacturer, and exporter of Stainless Steel 321H Pipes in Dubai, India. Our cutting-edge solutions cater to all your piping needs. With state-of-the-art production facilities strategically located in the India, we maintain a vast inventory of over 16,000 tons of premium-quality materials, ensuring we have the stock readily available to meet your demands.

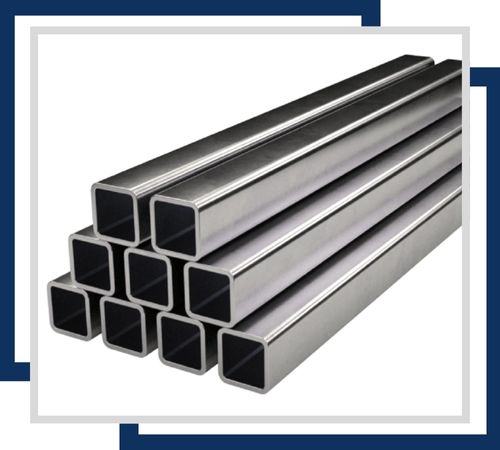

Stainless Steel 321H Square Pipes offer excellent resistance to intergranular corrosion, especially in high-temperature applications. They typically come in sizes ranging from 20 mm to 200 mm on each side, providing robust structural support and versatility for various industries.

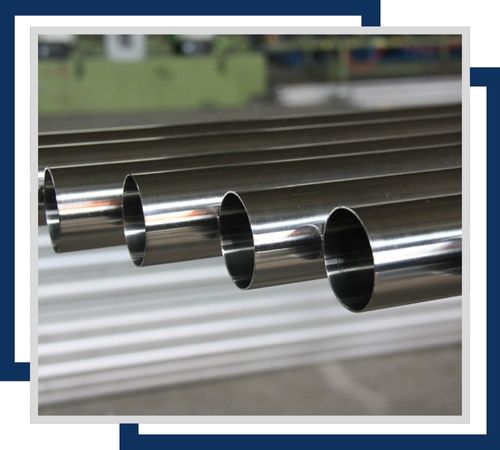

Known for its resistance to oxidation and corrosion, SS 321H Seamless Pipes are manufactured without welds or joints, offering uniformity and strength. They are available in 6 mm to 300 mm diameter and are suitable for high-pressure and high-temperature environments.

Featuring good resistance to corrosion and elevated temperatures, Stainless Steel 321H ERW (Electric Resistance Welded) Pipes are produced using electric resistance welding techniques. They are available from 15 mm to 150 mm, ideal for pipelines and structural applications.

SS 321H LSAW (Longitudinal Submerged Arc Welded) Pipes resist high-temperature oxidation and corrosion. These pipes are 60 mm to 1000 mm in diameter and are commonly used in oil and gas transmission and large-diameter piping systems.

Stainless Steel 321H Round Pipes are versatile and widely used with strong resistance to scaling and corrosion. They are available in diameters ranging from 10 mm to 500 mm, making them suitable for various industrial applications, including chemical processing.

Offering excellent resistance to intergranular corrosion, Stainless Steel 321H Welded Pipes are produced by welding and are ideal for applications where joints and fittings are required. They typically come in sizes ranging from 15 mm to 600 mm in diameter, suitable for various structural and mechanical uses.

Harshita Stainless is a leading supplier, and stockist of high-quality Stainless Steel 321H Pipes in Dubai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

You’ll find Stainless Steel 321H Pipes commonly used in high-temperature settings like furnaces, heat exchangers, boiler tubes, and exhaust systems. Their ability to resist oxidation and thermal fatigue makes them perfect for power plants, petrochemical refineries, aerospace, and chemical processing industries. These pipes are especially favored in applications that involve thermal cycling and welded structures, where durability and corrosion resistance are paramount. Plus, they’re also suitable for the food processing and pharmaceutical sectors, where hygiene and long-term performance under heat stress are crucial.

©2024 Harshita Stainless All Rights Reserved.