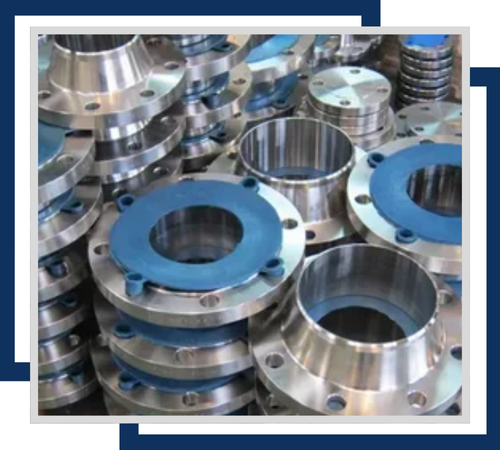

Harshita Stainless, based in Delhi, India, is a trusted manufacturer and supplier of high-performance Stainless Steel 321H Flanges, specifically crafted to handle the challenges of high-temperature and pressure applications. Renowned for their quality craftsmanship, precision engineering, and commitment to global standards, Harshita Stainless provides flanges that boast impressive strength, corrosion resistance, and weldability. The Stainless Steel 321H, a high-carbon variant of 321, is particularly suited for environments that demand enhanced creep resistance. Harshita Stainless offers these flanges in a range of sizes, pressure classes, and configurations, catering to essential sectors such as power plants, chemical industries, oil refineries, and high-temperature process systems.

Stainless Steel 321H is a titanium-stabilized austenitic stainless steel with a higher carbon content (0.04–0.10%) that enhances its high-temperature strength. It features 17–19% chromium, 9–12% nickel, and up to 0.7% titanium, which helps prevent carbide precipitation during welding. The 321H flanges deliver tensile strength ranging from 515–620 MPa, yield strength between 205–275 MPa, elongation of 40–50%, and a hardness of 80–90 HRB. These characteristics make them ideal for high-temperature service and welded structures that face thermal stress.

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/8″ NB TO 48″ NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti | SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We offers the best quality Stainless Steel 321H Flanges Harshita Stainless,which has undergone intense testing to produce top quality and performance. The flange is thoroughly tested for meeting international standards and specifications. Products supplied by us are certified by recognized authorities for traceability and reliability in each batch. With modern technology and strict quality control, we ensure durability, corrosion resistance, and good mechanical properties. Harshita Stainless stands by the delivery of flanges with the highest level of industry standards in functionality and safety.

SS 321H Slip-On Flanges are designed for easy installation and alignment, with sizes ranging from 1/2″ to 24″ in diameter. They offer excellent resistance to high-temperature oxidation and corrosion. Ideal for applications where moderate strength and corrosion resistance are required.

Stainless Steel 321H Weld Neck Flanges are available in sizes from 1/2″ to 24″ and feature a long tapered hub for superior strength and leak-proof performance. They are highly resistant to oxidation and corrosion, making them suitable for high-pressure environments.

SS 321H Blind Flanges come in sizes from 1/2″ to 24″ and are used to seal the end of a piping system. They provide excellent resistance to high temperatures and corrosive environments, ensuring a secure and leak-tight closure.

Stainless Steel 321H Threaded Flanges are available in sizes ranging from 1/2″ to 24″ and are designed for easy assembly without welding. They offer good resistance to oxidation and corrosion, making them suitable for various industrial applications.

SS 321H Socket Weld Flanges, ranging from 1/2″ to 24″ in size, are designed to fit inside a pipe for strong, reliable connections. They provide excellent resistance to high-temperature environments and corrosive substances.

Stainless Steel 321H Lap Joint Flanges are available in sizes from 1/2″ to 24″ and are used with a backing flange to allow for easy alignment and assembly. They offer high resistance to oxidation and corrosive elements, ideal for applications with frequent disassembly.

You’ll find Stainless Steel 321H Flanges commonly used in refineries, thermal power plants, chemical processing units, heat exchangers, and furnace systems, thanks to their outstanding resistance to oxidation and high-temperature corrosion. Their elevated carbon content boosts creep and stress rupture resistance, making them perfect for boiler components, piping systems, and flue gas environments. These flanges perform reliably in cyclic heating applications and are particularly advantageous in welded structures where intergranular corrosion might be a concern. Plus, they’re also utilized in the pharmaceutical and food processing industries, where sanitary, durable, and heat-resistant connections are crucial.

©2024 Harshita Stainless All Rights Reserved.