Harshita Stainless, located in Delhi, India, stands out as a top manufacturer and supplier of premium Stainless Steel 321 Coils. Our coils are expertly designed to perform exceptionally well in high-temperature and corrosive settings, making them perfect for a variety of industrial uses. Renowned for their outstanding oxidation resistance and stability, our Stainless Steel 321 Coils adhere to strict quality standards and are built to endure thermal cycling without losing strength. Industries like aerospace, chemical, and automotive trust our coils for their reliable and durable solutions, tailored to meet the unique needs of today’s manufacturing landscape.

Stainless Steel 321 Coils are made up mainly of chromium (17-19%), nickel (9-13%), and titanium (0.7%), which helps prevent carbide precipitation and boosts resistance to intergranular corrosion. This alloy boasts impressive mechanical properties, featuring a tensile strength of around 75 ksi and good elongation of about 30%. The titanium stabilization enhances the coil’s performance at high temperatures, reaching up to 870°C, by preserving structural integrity and avoiding grain boundary weakening. Additionally, these coils exhibit excellent toughness and oxidation resistance, making them a dependable choice for demanding, heat-intensive industrial environments.

| Specifications | ASTM A240, ASME SA240 |

| Standard | JIS, ASTM, AISI, GB, EN, DIN |

| Surface | 2B, BA, HL, No. 4, Mirror etc. |

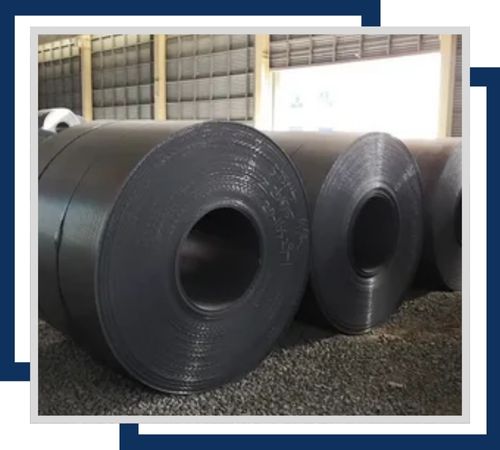

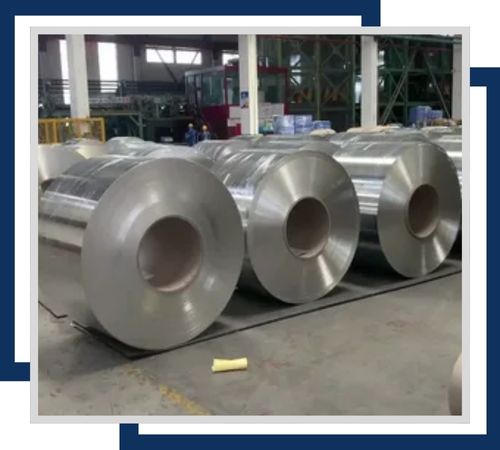

| Finish | Cold rolled, Hot rolled |

| Thickness | 0.3mm–100mm |

| Size | 1000mm, 1219mm, 1250mm, 1500mm, 1524mm, 2000mm |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 321 | 515 | 205 | 40 | 95 | 217 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

Contact us to get a quick quote for your requirement.

SS 321 slitting coils are stainless steel strips, processed through slitting, ideal for high-temperature applications due to their excellent resistance to corrosion and oxidation. Used in various industrial sectors

SS 321 hot-rolled coils are stainless steel sheets produced by heating and rolling, offering excellent resistance to corrosion and high temperatures, suitable for automotive, aerospace, and industrial applications,

SS 321 cold-rolled coils are stainless steel sheets processed at room temperature, providing a smooth surface and precise dimensions, ideal for applications requiring excellent corrosion resistance and structural integrity.

Stainless Steel 321 HR slitting coils are hot-rolled, slit stainless steel strips, offering excellent heat and corrosion resistance. They are used in industries requiring high durability and precision.

Stainless Steel 321 slitting coils are precision-cut strips of heat-resistant stainless steel, ideal for applications requiring high corrosion resistance and strength, commonly used in aerospace, automotive, and industrial sectors.

AISI 321 slitting coils are stainless steel strips with excellent heat and corrosion resistance, processed by slitting. They’re suitable for applications in aerospace, automotive, and high-temperature environments.

We ensure that our documentation for Stainless Steel 321 Coils is detailed and reliable to provide complete transparency. The documents include a commercial invoice, a packaging list, a fumigation certificate, a heat treatment chart, and a quality assurance plan. The package further comprises an NABL-approved lab test report for confirmation against rigorous standards. For enhancing our commitment to quality, we provide several test certificates such as MTC according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and a Third-Party Inspection Certificate. Such strong measures guarantee 100% client satisfaction and confidence in the integrity of our Stainless Steel 321 Coils.

Stainless Steel 321 Coils find extensive use in industries that require durability against high temperatures and corrosive conditions. They are frequently utilized in the production of heat exchangers, furnace components, exhaust systems, and chemical processing equipment. Thanks to the titanium stabilization, they are particularly suited for applications involving thermal cycling, such as aerospace parts, power plants, and automotive exhaust systems. Their remarkable resistance to oxidation and corrosion also makes them ideal for the petrochemical and food processing sectors. With Harshita Stainless’s 321 Coils, you can count on durability and performance that meet the challenges of modern industry.

©2024 Harshita Stainless All Rights Reserved.