Stainless Steel 321 bars are produced by leading manufacturers in Dubai and India for use in applications that require resistance to intergranular corrosion and high-temperature strength. These bars, made from titanium-stabilized austenitic stainless steel, keep their structure under cyclic heating and corrosive conditions. Available in round, hex, square, and flat profiles, SS 321 bars comply with ASTM A276 and A479 standards. They are used in fabrication, pressure vessels, heat exchangers, and chemical processing. Manufacturers provide customized lengths, polished finishes, and tested mechanical properties, ensuring dependable performance in structural and high-temperature industrial components.

Stainless Steel 321 contains 17–19% chromium, 9–12% nickel, and a minimum titanium amount of five times the carbon percentage. Carbon is usually ≤0.08%. The alloy shows a tensile strength between 515–620 MPa, a yield strength of around 205 MPa, and an elongation of about 35%. SS 321 provides better oxidation and creep resistance at temperatures up to 870°C. The addition of titanium prevents sensitization and keeps corrosion resistance intact after welding or prolonged heat exposure. This blend of mechanical and chemical properties makes the bars suitable for high-stress, high-temperature environments where reliable performance is vital.

Standard : 321 / 1.4541

Range : 3.17mm to 350mm dia

Designation : ASTM A276, ASME SA276

Finish : Bright, Black, Polish

Thickness: 4.0mm – 100mm

Type: Bar, Bright Bar, Black Bars, Hex Bar, Square Bar, Rods, Polish Bar, Forged Bar, Round Bar

Length : Random, Fix & Cut Length

Grade | Mn | N | P | C | S | Cr | Mo | Si | Ni | Other | |

321 Stainless Steel Nuts | minimum maximum | 2.00 | 0.10 | 0.045 | – 0.08 | 0.030 | 17.0 19.0 | – | 0.75 | 9.0 12.0 | Ti=5(C+N) 0.70 |

Grade | Tensile Strength (MPa) minimum | Yield Strength 0.2% Proof (MPa) minimum | Elongation (% in 50mm) minimum | Hardness | |

Rockwell B (HR B) maximum | Brinell (HB) maximum | ||||

321 Stainless Steel Nuts | 515 | 205 | 40 | 95 | 217 |

Contact us to get a quick quote for your requirement.

At Harshita Stainless, 321 stainless steel panels are rigorously tested to ensure compliance with international quality standards. Necessary documentation, including material test reports (MTRs), chemical and mechanical analyses, and third-party testing certificates, is provided to ensure reliability, durability and accurately defined for industrial applications

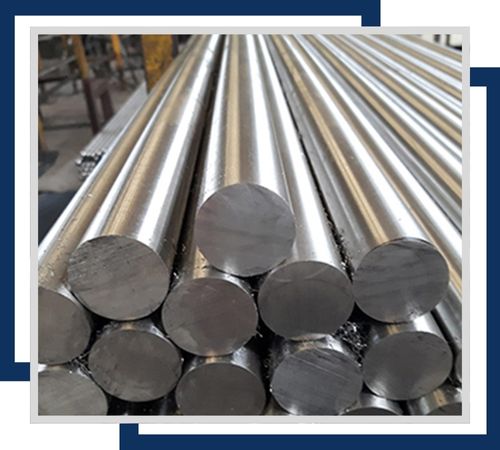

Stainless Steel 321 Round Bars Corrosion-resistant product with excellent high-temperature stability. Available in diameters from 0.5″ to 12″, ideal for aerospace and chemical processing applications where durability is critical.

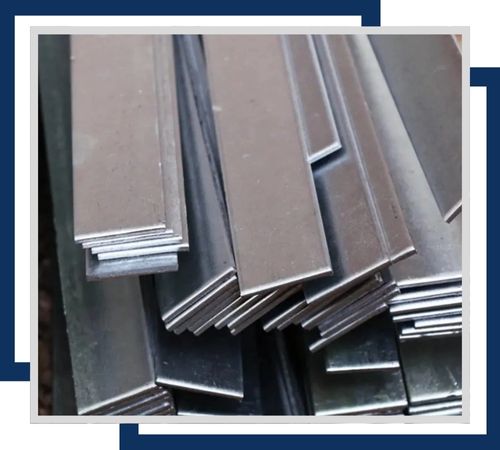

Stainless Steel 321 Flat Bars This product offers superior resistance to oxidation and is available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural and high-temperature applications.

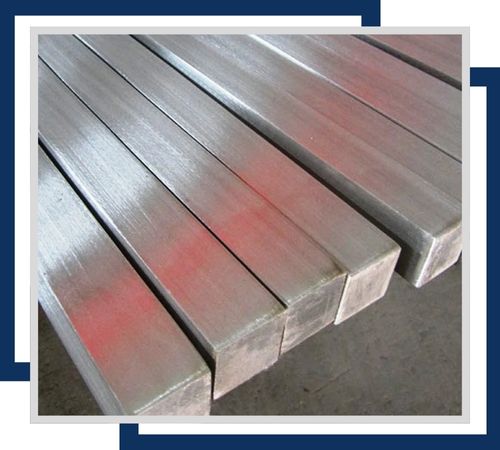

Stainless Steel 321 Square Bars Corrosion-resistant product designed for strength, available in sizes ranging from 0.5″ to 6″ on each side. Suitable for industrial applications requiring high-temperature performance.

This Corrosion-resistant product with dimensions from 0.5″ x 1″ to 6″ x 12″. Ideal for use in heavy-duty applications and structures where thermal stability is essential.

Stainless Steel 321 Hexagonal Bars Corrosion-resistant product available in sizes from 0.5″ to 4″ across flats. Used in aerospace and chemical industries where high-temperature resistance is required.

Stainless Steel 321 T-Bars Corrosion-resistant product with dimensions ranging from 0.5″ x 0.5″ to 6″ x 6″. Suitable for structural support and applications demanding high-temperature stability and strength.

©2024 Harshita Stainless All Rights Reserved.