Home > Sheet and Plates > Stainless Steel 321/321H Sheet and Plates

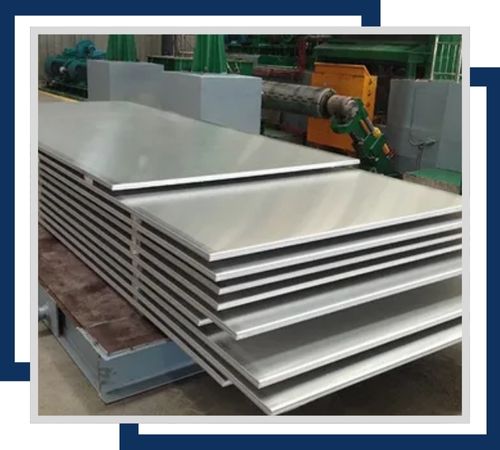

Stainless Steel 321 and 321H Sheets and Plates are a type of titanium-stabilized austenitic stainless steel, celebrated for their outstanding resistance to intergranular corrosion and impressive performance at high temperatures. These materials shine in applications where they face continuous exposure to temperatures ranging from 800°F to 1500°F (427°C to 816°C), especially in situations where carbide precipitation could be a concern with standard 304 or 316 grades. The 321H variant, which has a higher carbon content, offers even greater strength at elevated temperatures. Both grades deliver dependable mechanical performance and oxidation resistance, making them perfect for use in pressure vessels, heat exchangers, exhaust systems, and various high-temperature industrial equipment.

When it comes to the chemical makeup, Stainless Steel 321 typically contains 17–19% chromium, 9–12% nickel, and titanium levels that are at least five times the carbon content to help prevent carbide formation. On the other hand, 321H has a similar composition but with a higher carbon content (0.04–0.10%) to enhance creep strength. These materials boast a tensile strength of about 515 MPa and a yield strength of around 205 MPa, along with good elongation and ductility. They maintain their strength and corrosion resistance even in high-heat settings, offering excellent weldability and formability compared to non-stabilized grades.

Specifications: ASTM A240 / ASME SA240

Dimensions: ASTM, ASME, and API.

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness:4mm-100mm

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc

Form: Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

These sheets contain high corrosion resistance and are available up to 1.2-12mm thickness and width up to 2000mm. They are ideal for high temperature application.

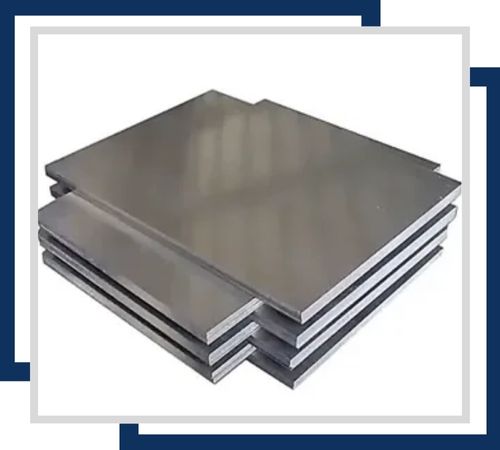

Cold rolled plates of SS 321H possess higher corrosion resistance and are available up to 0.3-6mm in thickness and up to 1500mm in width. They are perfect for applications requiring a smooth finish and high strength.

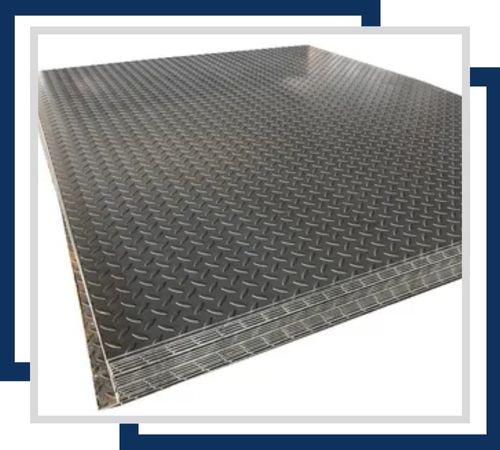

These plates provide outstanding resistance to corrosion, and come in thickness from 3mm up to 12mm and have sizes of up to 1500mm x 3000mm. Raised pattern surface increases the gripping value, thus commonly used for floor and structural work.

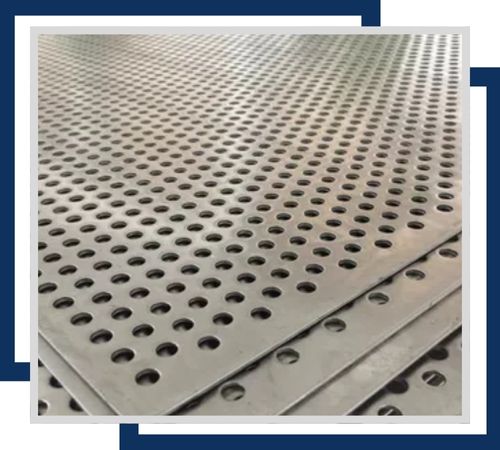

Perforated sheets are extremely resistant to corrosion and can be perforated from 0.5mm up to 20mm in diameter. The sheet thickness is also from 0.3mm up to 3mm. It is used in filtration and ventilation systems.

Shim sheets are resistant to corrosion with a high accuracy level. Thickness is available between 0.05mm up to 3mm, and cut-to-size service is also possible to get precise dimensions for several alignment and spacing applications.

Polished plates have excellent resistance to corrosion, and a reflective finish. These plates are manufactured in thickness range from 3mm to 50mm. The size for these plates up to 2000mm x 6000mm is ideal for aesthetic applications as well as a high-quality surface finish.

Harshita Stainless offers an excellent customer experience along with detailed documentation of its high-quality Stainless Steel 321/321H Sheets and Plates. We deliver key documents such as the commercial invoice, packing list, fumigation certificate, heat treatment chart, quality assurance plan, and NABL-approved lab test report, making it easier to validate the authenticity and superior quality of our products for the value-added customers. Our Stainless Steel 321/321H Sheets and Plates, meanwhile, possess diversified test certificate features, ranging from MTC accordance with EN10204 /3.1B to a PMI test Certificate, radiographic test reports having 100 % and even up to third Party Inspection. Here, too the certificates explain their customer-driven activities and unwearied product quest for superior product quality.

You’ll find Stainless Steel 321/321H Sheets and Plates in a variety of industries, including aerospace, chemical processing, oil and gas, power generation, and thermal processing. They’re commonly used in applications like aircraft exhaust manifolds, furnace components, expansion joints, heat exchanger tubing, and petrochemical piping systems. Their ability to resist oxidation and stress rupture at elevated temperatures makes them a go-to choice for high-temperature service. Plus, their resistance to intergranular corrosion after welding ensures a long service life in challenging thermal environments, minimizing the risk of cracking or premature failure.

©2024 Harshita Stainless All Rights Reserved.