Harshita Stainless stands out as a top-notch manufacturer and supplier of Stainless Steel 316Ti Tubing, specifically designed to meet the unique demands of industries in Dubai and India. Based in Delhi, India, this company has built a reputation for providing high-quality stainless steel tubing that boasts impressive corrosion resistance, high-temperature strength, and remarkable durability. The Stainless Steel 316Ti Tubing is a sophisticated titanium-stabilized variant of 316 stainless steel, making it perfect for applications that require extended exposure to high temperatures and harsh environments. With a commitment to quality, precision, and timely delivery, Harshita Stainless caters to various sectors, including petrochemical, marine, pharmaceutical, and power generation.

This tubing is made up of iron, containing 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and a touch of titanium, which helps stabilize the alloy and prevent sensitization. It boasts a tensile strength of around 515 MPa and a yield strength of about 205 MPa, along with excellent creep resistance and structural integrity even at elevated temperatures. The inclusion of titanium makes it particularly well-suited for welded structures that face temperatures exceeding 400°C.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A269 / ASTM SA269

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 316TI |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316TI |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 75 |

| Brinell (HB) max | 205 |

Contact us to get a quick quote for your requirement.

This steel 316Ti tubing from Harshita Stainless is thoroughly inspected for pitting and intergranular corrosion resistance, tensile strength, and hardness, apart from hydrostatic pressure testing for premium quality, and is accredited and approved to international specifications like ASTM, ASME, and ISO against each material test report.

Stainless Steel 316Ti Seamless Tubing is known for its superior corrosion resistance, especially in high-temperature environments. Typically available in sizes ranging from 1/8” to 12” OD, it offers excellent mechanical properties and smooth surface finishes. Ideal for applications requiring high precision and reliability.

Stainless Steel 316Ti Welded Tubing combines excellent corrosion resistance with durability. Available in sizes from 1/8” to 24” OD, this tubing is cost-effective and versatile for various applications. It is particularly suitable for industries where high resistance to oxidizing acids is essential.

Stainless Steel 316Ti Heat Exchanger Tubes are designed for optimal thermal conductivity and corrosion resistance. These tubes come in sizes ranging from 1/4” to 2” OD, making them perfect for heat exchangers in chemical processing and power generation industries. They ensure efficient heat transfer and long service life.

Stainless Steel 316Ti Instrumentation Tubing offers superior corrosion resistance and precision. Available in sizes from 1/16” to 1” OD, it is ideal for high-pressure and high-temperature applications in instrumentation and control systems. Ensures reliable performance and accuracy in critical applications.

Stainless Steel 316Ti Boiler Tubes are engineered for high temperature and pressure conditions. Sizes range from 1/2” to 5” OD, providing excellent resistance to oxidation and corrosion. These tubes are essential for maintaining efficiency and longevity in boiler systems

Stainless Steel 316Ti U-Tubes are designed for heat exchangers and boiler systems where space-saving is crucial. Available in sizes from 1/4” to 1” OD, they offer exceptional corrosion resistance and flexibility in design. Ideal for applications requiring compact and efficient thermal transfer solutions

Stainless Steel 316Ti Condenser Tubes provide excellent corrosion resistance and thermal conductivity. Sizes range from 1/4” to 2” OD, making them suitable for condensers in power plants and HVAC systems. Ensures efficient condensation and long-term performance

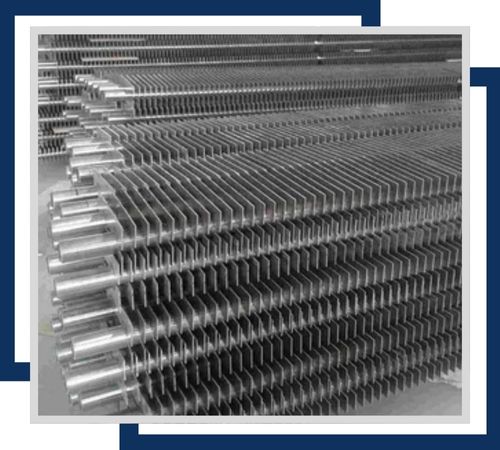

Stainless Steel 316Ti Fin Tubes enhance heat transfer efficiency while maintaining high corrosion resistance. Available in sizes from 1/4” to 1-1/2” OD, these tubes are used in heat exchangers, condensers, and evaporators. The finned design maximizes surface area for optimal thermal performance.

Stainless Steel 316Ti Tubing finds its place in high-performance applications like heat exchangers, marine piping, chemical processing lines, pressure systems, and pharmaceutical equipment. Its resistance to pitting, crevice corrosion, and oxidation makes it a go-to choice for transporting corrosive fluids or gases in challenging environments. Industries in Dubai and India trust 316Ti tubing for its long-lasting stability, mechanical strength, and outstanding resistance to chloride-induced corrosion and high thermal stress.

©2024 Harshita Stainless All Rights Reserved.