Harshita Stainless is a well-respected manufacturer and supplier based in Delhi, India, specializing in top-notch Stainless Steel 316H Tubing designed for high-temperature and high-pressure applications. This grade stands out due to its higher carbon content compared to standard 316, which enhances its strength and creep resistance, making it perfect for tough industrial settings. Harshita Stainless prides itself on delivering tubing solutions with meticulous craftsmanship, strict adherence to international quality standards, and a strong focus on customer satisfaction. With an extensive distribution network and a dedication to quality, the company has established itself as a trusted partner for industries like petrochemical, power generation, oil & gas, and heat exchanger manufacturing both in India and internationally.

Stainless Steel 316H is a high-carbon version of 316, featuring 0.04–0.10% carbon, 16–18% chromium, 10–14% nickel, and 2–3% molybdenum. The added carbon boosts its strength at high temperatures, making it suitable for elevated service conditions. Typically, SS 316H tubing boasts a tensile strength of 515 MPa and a yield strength of 205 MPa, along with impressive ductility and toughness. It maintains its structural integrity under thermal stress and offers excellent resistance to oxidation and general corrosion, especially in harsh and high-temperature industrial environments.

Specifications : ASTM A213, A312, A269, A358 / ASME SA213, SA312, SA269, SA358

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type : Seamless / ERW / Welded / Fabricated / CDW

Form : Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

Outside Finish : 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Tubes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We ensures high-quality Stainless Steel 316H Tubing through hydrostatic, ultrasonic, PMI (Positive Material Identification), and intergranular corrosion tests. Every batch is inspected in detail to meet the standards of ASTM and ASME. ISO, EN, and NACE certified, all products are delivered with material test reports and compliance certificates.

Stainless Steel 316H Seamless Tubing is available in sizes ranging from 1/8″ to 24″ in diameter. Known for its superior corrosion resistance, it is ideal for high-temperature applications. The absence of welds ensures a smooth finish and higher strength.

Stainless Steel 316H Welded Tubing is available in sizes from 1/8″ to 72″ in diameter. It offers excellent corrosion resistance and is suitable for a variety of applications, including chemical and petrochemical industries. The welding process allows for cost-effective production of longer lengths.

Stainless Steel 316H Heat Exchanger Tubes come in sizes from 1/2″ to 12″ in diameter. They are designed for optimal heat transfer and corrosion resistance, making them ideal for high-temperature environments. These tubes are essential components in heating and cooling systems.

Stainless Steel 316H Instrumentation Tubing is available in sizes from 1/8″ to 1″ in diameter. It offers high corrosion resistance and precise dimensional tolerances, making it perfect for use in critical instrumentation and control systems. These tubes ensure reliable performance under high pressure.

Stainless Steel 316H Boiler Tubes range in size from 1/2″ to 5″ in diameter. They provide excellent corrosion resistance and can withstand high temperatures and pressures. These tubes are essential in the construction of boilers and pressure vessels.

Stainless Steel 316H U-Tubes are available in sizes from 1/2″ to 1-1/2″ in diameter. They are specifically designed for heat exchanger applications where space is limited, offering superior corrosion resistance. The U-shape allows for efficient heat transfer in compact spaces.

Stainless Steel 316H Condenser Tubes come in sizes from 1/4″ to 2″ in diameter. They provide excellent corrosion resistance and are used in condensers and evaporators. These tubes are critical for effective heat exchange in various industrial processes.

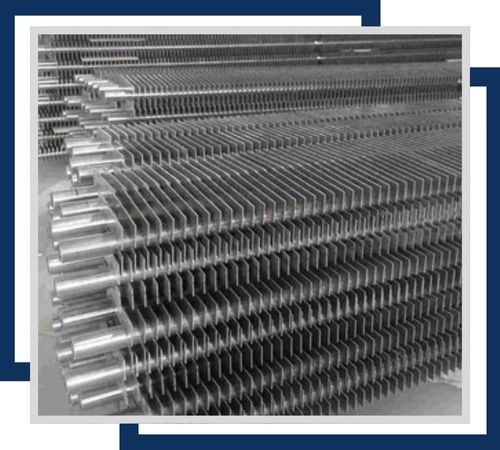

Stainless Steel 316H Fin Tubes are available in sizes from 1/2″ to 2″ in diameter. They are designed with fins to increase the surface area for better heat transfer, offering high corrosion resistance. These tubes are ideal for heat exchangers and air conditioning systems.

Stainless Steel 316H Tubing finds extensive use in high-temperature applications where outstanding mechanical strength and corrosion resistance are essential. It’s commonly utilized in heat exchangers, superheaters, boilers, pressure vessels, and power plants. Industries such as petrochemical, oil and gas refining, pulp and paper, and chemical processing depend on 316H tubing for its performance in elevated temperatures and corrosive conditions. Its exceptional creep resistance and strength retention at high temperatures make it an ideal choice for furnace components and reactor tubes, ensuring reliability in demanding applications.

©2024 Harshita Stainless All Rights Reserved.