A top producer and supplier of stainless steel 316H bars, Harshita Stainless is based in Delhi, India, and provides premium stainless steel solutions for high-temperature and high-pressure settings. SS 316H bars from Harshita Stainless are extensively utilised in demanding industrial sectors and are renowned for their precise manufacturing, reliable quality, and timely delivery. High carbon austenitic stainless steel, which provides exceptional strength and resistance to corrosion, is used to make these bars. The company provides long-lasting, high-performance stainless steel bar products to the petrochemical, power generation, oil and gas, and refinery industries, all while adhering to international standards.

Chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and a higher carbon content (up to 0.10%) are all present in stainless steel 316H bars. This composition improves creep resistance and strength at high temperatures. The bars exhibit excellent mechanical properties, including tensile strength around 515 MPa and yield strength approximately 205 MPa. In environments that are acidic and chloride-rich, SS 316H bars provide strong resistance to oxidation and corrosion while maintaining their structural integrity at high temperatures. These characteristics make them perfect for components exposed to corrosive industrial atmospheres and for fabrication in heat-intensive applications.

Specifications : ASTM A276, ASME SA276 / ASTM A479 ASME SA479

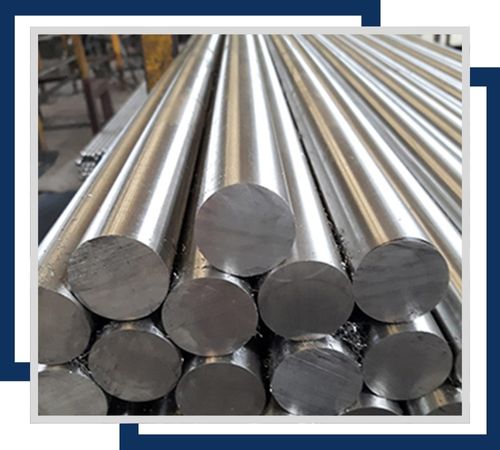

Round Bars : Outside Diameter in the range of 4mm to 500mm

Bright Bars : Outside Diameter in the range of 4mm to 100mm

Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″)

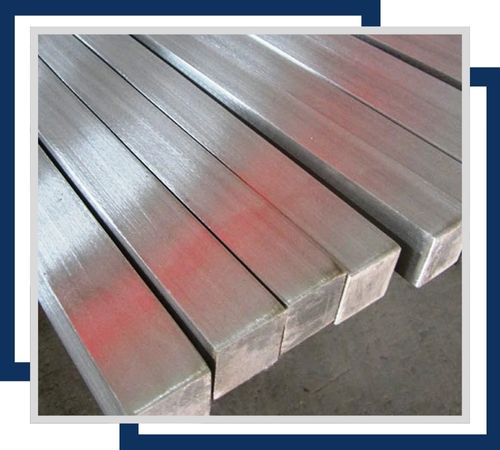

Square Bars : 18mm – 47mm (11/16″ to 1-3/4″)

Length : 1 to 6 Meters, Custom Cut Lengths

Form : Round, Square, Hex (A/F), Rectangle Etc.

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We ensures the highest quality of stainless steel 316H tiles through rigorous testing and certification. Extensive testing is carried out, including chemical composition analysis, mechanical testing and corrosion resistance analysis. Our breweries are certified to meet international standards, providing customers with reliable, robust, and performance-based solutions for a variety of applications.

Stainless Steel 316H Round Bars are engineered for high-temperature environments, offering excellent strength and corrosion resistance. Ideal for use in chemical processing, petrochemical industries, and power generation applications where durability and resistance to heat are crucial.

Stainless Steel 316H Flat Bars are designed for high-temperature applications requiring exceptional strength and corrosion resistance. Suitable for use in manufacturing equipment for chemical processing, high-temperature environments, and marine applications.

Stainless Steel 316H Square Bars provide superior high-temperature strength and corrosion resistance. They are commonly used in the construction of industrial equipment, chemical reactors, and components exposed to severe thermal conditions.

Stainless Steel 316H Rectangular Bars are ideal for applications demanding high strength and resistance to heat. These bars are utilized in chemical processing, marine environments, and high-temperature industrial applications where durability is essential.

Stainless Steel 316H Hexagonal Bars offer high-temperature strength and exceptional corrosion resistance. They are suited for use in marine environments, chemical processing, and applications requiring robust performance under extreme conditions.

Stainless Steel 316H T-Bars are designed for high-stress, high-temperature applications, providing excellent strength and resistance to corrosion. Ideal for use in structural components, chemical processing equipment, and other demanding industrial applications.

Industries that require high mechanical strength, thermal stability, and corrosion resistance frequently use stainless steel 316H bars. They are used in reactors, heat exchangers, and pressure vessels in the petrochemical and chemical processing industries. Because of their superior creep resistance, they are used in boiler components and superheaters in power generation facilities. 316H bars are essential to the oil and gas sector for offshore structures and high-pressure pipelines. They are also utilised in furnace components, welded fabrications subjected to high temperatures, and refinery equipment. Their ability to withstand harsh chemical and thermal environments makes them ideal for demanding industrial applications.

©2024 Harshita Stainless All Rights Reserved.