Harshita Stainless, a prominent manufacturer and supplier located in Delhi, India, specializes in high-quality Stainless Steel 316 Tubing, renowned for its outstanding corrosion resistance, strength, and versatility. This tubing is crafted to meet the rigorous demands of various industries, making it perfect for marine, chemical, pharmaceutical, and food processing applications. At Harshita Stainless, each tube is meticulously produced to meet international quality standards and the specific needs of clients. With a strong focus on consistent quality, timely delivery, and customer satisfaction, the company has established a solid reputation in both domestic and international markets, providing reliable and high-performance stainless steel tubing solutions.

Stainless Steel 316 tubing is composed of 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, which significantly boosts its resistance to pitting and crevice corrosion, especially in chloride-rich environments. It boasts a tensile strength of about 515 MPa and a yield strength of around 205 MPa, along with impressive elongation and ductility. SS 316 tubing retains its strength and toughness even at cryogenic temperatures and shows good resistance to high-temperature oxidation. The alloy’s well-balanced composition guarantees exceptional mechanical performance, corrosion resistance, and formability, making it ideal for both structural and fluid transfer applications in challenging operating conditions.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubing

| SS | 316 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

Contact us to get a quick quote for your requirement.

We offers high quality stainless steel 316 tubing, rigorously tested for durability, corrosion resistance and accuracy. Each tube undergoes extensive testing, including mechanical and chemical analysis, to ensure it meets industry standards. Certificates of conformity (CoC) are issued, confirming that products meet all specified requirements for performance and safety.

This tubing is available in sizes ranging from 1/8″ to 12″ in diameter and is known for its excellent corrosion resistance, particularly in marine and chemical environments. The seamless construction ensures high strength and reliability.

Typically offered in sizes from 1/4″ to 8″ in diameter, this tubing is fabricated by welding stainless steel sheets. It provides good corrosion resistance, making it suitable for structural applications and chemical processing.

Designed for heat exchange applications, this tubing generally comes in sizes from 1/2″ to 2″ in diameter. It boasts superior corrosion resistance and thermal conductivity, ideal for use in heat exchangers and condensers.

Available in sizes from 1/16″ to 1″ in diameter, this tubing is used in high-pressure and precision applications. It offers excellent resistance to corrosion and is ideal for instrumentation and process control systems.

Typically found in sizes from 1″ to 5″ in diameter, these tubes are designed for high-temperature and high-pressure environments. They provide strong corrosion resistance and durability for boiler systems.

Used in heat exchangers and other applications requiring a U-shaped tube, sizes range from 1/2″ to 4″ in diameter. They offer high resistance to corrosion and are designed for effective thermal performance.

This type comes in sizes from 1/2″ to 2″ in diameter and is used in condensers for its excellent corrosion resistance and durability in cooling applications. Ideal for heat transfer and cooling systems.

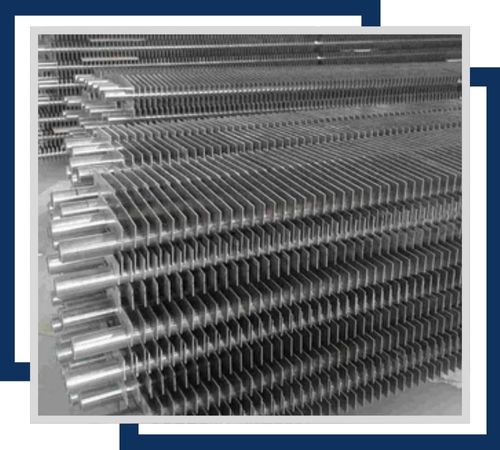

Typically available in diameters from 1/2″ to 2″, these tubes have fins attached to enhance heat transfer efficiency. They are highly resistant to corrosion and are used in heat exchangers and other cooling systems.

Stainless Steel 316 Tubing is extensively utilized across a range of industries due to its excellent corrosion resistance and mechanical reliability. You can commonly find it in chemical processing plants, marine settings, pharmaceutical equipment, and food and beverage production systems where sanitary and corrosion-resistant materials are crucial. Additionally, SS 316 tubing is employed in heat exchangers, condensers, hydraulic lines, medical devices, and offshore oil and gas installations. Its remarkable ability to withstand chlorides makes it a preferred choice in these demanding environments.

©2024 Harshita Stainless All Rights Reserved.