Harshita Stainless is a leading Dubai-based manufacturer and supplier of stainless steel products in India. We are engaged in offering high-quality stainless steel solutions in various forms, including the long-lasting and dependable Stainless Steel 309S Tubing with good oxidation and corrosion properties. Our specialty includes manufacturing precision-engineered products that fulfill the crucial requirements of different industries. With a firm focus on performance, innovation, and on-time delivery, Harshita Stainless has emerged as a reliable business partner for customers across industries, offering stainless steel tubing solutions complying with international standards and performing well in harsh industrial conditions.

Stainless Steel 309S Tubing is an austenitic chromium-nickel alloy that is specifically meant for high-temperature and corrosion-resistant service applications. It has 24–26% chromium, 12–22% nickel, and trace levels of manganese, silicon, and carbon (≤0.08%), which provide weldability and resistance to sensitization. It has good oxidation resistance and can excel in high-heat conditions. Mechanical properties are 515 MPa tensile strength, 205 MPa yield strength, and 40% elongation. These characteristics render 309S tubing suitable for application in structural and welded assemblies operating at high temperatures and corrosive environments.

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Form | Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded. |

| ELEMENT | SS 309S |

| NI | 12.0 – 15.0 |

| C | 0.08 max |

| MN | 2.0 max |

| P | 0.045 max |

| S | 0.030 max |

| SI | 1.0 max |

| CR | 22.0 – 24.0 |

| MO | 0.75 max |

| Condition & Grade | Tensile Strength | Yeild Strength | Elognation | Hardness |

|---|---|---|---|---|

| SS 309S | 75 (515) | 30 (205) | 35 | 90 HRB max |

Contact us to get a quick quote for your requirement.

We ensures the highest quality stainless steel 309S tubing through rigorous testing procedures including mechanical, chemical and theoretical testing. Compliance with international standards is demonstrated by industry-standard documentation, such as material test certificates (MTCs). These certifications attest to the durability, strength and performance of the pipe.

Stainless Steel 309s Seamless Tubing is known for its high resistance to oxidation and excellent mechanical properties. It typically comes in diameters ranging from 1/8 inch to 12 inches, with wall thicknesses of 0.5 mm to 10 mm. It offers superior corrosion resistance in high-temperature applications.

Stainless Steel 309s Welded Tubing is ideal for applications requiring good oxidation resistance and strength. It is available in sizes from 1/4 inch to 10 inches in diameter and wall thicknesses from 0.5 mm to 8 mm. This tubing is well-suited for high-temperature environments due to its excellent corrosion resistance.

Stainless Steel 309s Heat Exchanger Tube is designed to handle extreme temperatures and corrosive environments. Common sizes range from 1/2 inch to 3 inches in diameter, with wall thicknesses of 1 mm to 5 mm. It provides excellent thermal conductivity and resistance to oxidation.

Stainless Steel 309s Instrumentation Tubing is used for precise measurement and control applications. It is available in sizes from 1/8 inch to 2 inches in diameter and wall thicknesses from 0.5 mm to 3 mm. This tubing offers strong resistance to high temperatures and corrosive environments.

Stainless Steel 309s Boiler Tubes are engineered for use in high-pressure and high-temperature environments within boilers. Typical sizes are from 1/2 inch to 4 inches in diameter, with wall thicknesses of 1 mm to 8 mm. They exhibit excellent resistance to thermal cycling and oxidation.

Stainless Steel 309s U-Tubes are used in heat exchangers and other applications requiring bending and high thermal resistance. Sizes generally range from 1/2 inch to 2 inches in diameter. They are highly resistant to thermal stress and corrosion.

Stainless Steel 309s Condenser Tube is designed for use in condenser systems where high heat resistance is critical. It comes in sizes from 1/2 inch to 3 inches in diameter and wall thicknesses from 0.5 mm to 4 mm. It provides excellent durability and resistance to corrosion and heat.

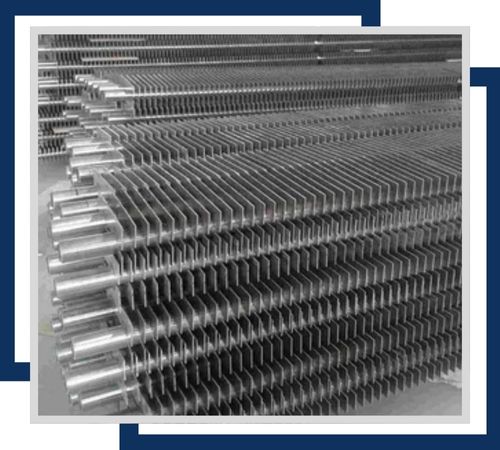

Stainless Steel 309s Fin Tubes are used in applications where enhanced heat transfer is needed, such as in heat exchangers and radiators. Typical sizes are from 1/2 inch to 2 inches in diameter, with various fin lengths and thicknesses. They offer good resistance to oxidation and high temperatures.

Stainless Steel 309S Tubing finds extensive applications in industrial sectors that require superior performance at elevated temperatures and corrosive environments. It is applicable to heat exchangers, furnace parts, welded constructions, and exhaust systems because of the capacity to resist temperatures higher than 1093°C (2000°F). Due to its strength and resistance to oxidation, 309S tubing is specifically suited for application in chemical processing, aerospace, and automotive markets. It also serves in food processing equipment and medical devices where cleanliness and durability are critical. With a long lifespan and high mechanical stability, 309S tubing is relied upon in hostile environments where failure is unacceptable.

©2024 Harshita Stainless All Rights Reserved.