Harshita Stainless is a well-known Dubai, India-based manufacturer and supplier of high-grade stainless steel products. We aim to deliver dependable, high-performance stainless steel solutions catering to the industrial sector. Our specialty product, Stainless Steel 309H Tubing, is designed for strength, heat endurance, and corrosion resistance. Employed extensively in high-temperature conditions, our 309H tubing is recognized for having an extended service period and structural stability. Our primary concern at Harshita Stainless is customer satisfaction, providing affordable and long-lasting stainless steel tube solutions with international quality standards, catering to the requirements of various industries in India and around the globe.

Stainless Steel 309H Tube consists of about 22% of chromium and 12–15% of nickel along with trace amounts of carbon (0.04–0.10%), manganese, silicon, and iron. The alloy provides great resistance against oxidation and scaling at high temperatures. Mechanical properties are a tensile strength of 515–690 MPa, yield strength of 205 MPa, and elongation of 40% at 50 mm. The high carbon content improves high-temperature strength and creep resistance. These tubes have excellent performance in severe thermal and chemical conditions and find use in heat-intensive uses while maintaining durability, weldability, and long-term reliability.

Tube Specifications: ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Dimensions: ANSI B36.19, ANSI B36.10

Pipe Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Tube Outside Diameter: 1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness Range: 1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Type: Seamless / ERW / Welded / Capillary Tubes

Form: Round Tube, Square Tube, Rectangular Tube

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Finish: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating: 3LPE / 3LPP/ FBE/ DFBE/ PP

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We offers thorough testing and certification of stainless steel 309H tubing, ensuring high performance and reliability. Our products undergo rigorous testing, including mechanical, chemical and theoretical analysis. Each batch is certified by relevant test reports, meets industry standards and customer specifications for durability, strength and corrosion resistance.

Available in sizes ranging from 1/8″ to 12″ in outer diameter, these tubes are highly corrosion-resistant. Seamless construction ensures strength and durability under high temperatures and pressures.

These tubes, with outer diameters from 1/8″ to 24″, offer excellent corrosion resistance. Welded for precise applications, they are suitable for a variety of industrial uses

Typically sized between 1/8″ and 2″ in outer diameter, this tubing is corrosion-resistant and designed to withstand high temperatures. Ideal for efficient heat transfer in industrial systems.

Available in sizes from 1/16″ to 2″ in outer diameter, it boasts high corrosion resistance. Perfect for critical instrumentation applications requiring precision and reliability.

Ranging from 1/2″ to 5″ in outer diameter, these corrosion-resistant tubes can endure extreme temperatures. Essential for maintaining efficiency in boiler operations.

These tubes come in various sizes, typically up to 2″ in outer diameter, and offer excellent corrosion resistance. They are used in heat exchangers and condensers for efficient thermal management.

With sizes usually between 1/4″ and 2″ in outer diameter, this corrosion-resistant tubing is designed for condensing steam or other fluids. It ensures efficient thermal exchange in condensers.

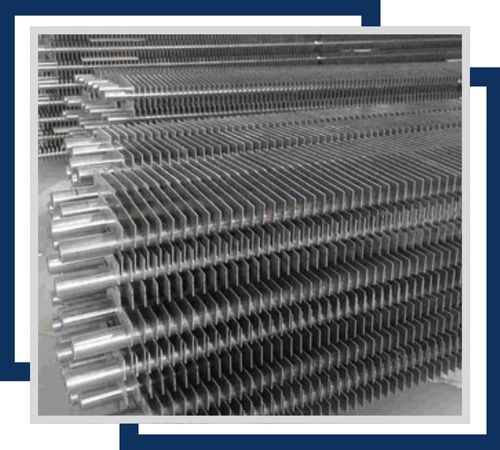

Available in sizes from 1/2″ to 2″ in outer diameter, these corrosion-resistant tubes feature fins for enhanced heat transfer. Used in heat exchangers to improve efficiency and performance.

Stainless Steel 309H Tubing is perfect for employment in high-pressure, high-temperature conditions where the strength of the material and its resistance to oxidation are significant. It is mostly employed in petrochemicals, power generation, heat treating, and furnace fabrication sectors. Some common applications are heat exchangers, combustion chambers, exhaust systems, boilers, and reactor vessels. Its corrosion resistance and thermal stability allow 309H tubing to endure thermal cycling and exposure to harsh chemicals for long service life. Its capacity to retain its mechanical properties at high heat is a major advantage for heavy-duty structural and process-based industrial applications where high performance is desired and continuous in nature.

©2024 Harshita Stainless All Rights Reserved.