Harshita Stainless, a prominent manufacturer and supplier located in Delhi, India, has made a name for itself by providing top-notch stainless steel products around the globe. With a focus on Stainless Steel 309 Bars, the company has carved out a significant presence in Dubai, UAE, by delivering high-quality bars that adhere to international standards. Committed to precision, durability, and customer satisfaction, Harshita Stainless ensures that every product goes through thorough quality checks. Their state-of-the-art manufacturing facilities and skilled team allow them to meet the rising demand in the Middle East, establishing them as a reliable player in the stainless steel sector.

Stainless Steel 309 Bars are primarily composed of chromium (22–24%) and nickel (12–15%), along with trace amounts of manganese, silicon, and carbon. These components provide outstanding resistance to oxidation and corrosion, even at elevated temperatures. The bars boast impressive mechanical properties, featuring a tensile strength of around 620 MPa, yield strength of 310 MPa, and a good elongation of about 45%. Their remarkable strength and heat resistance make them perfect for industrial applications that require durability and performance in extreme conditions, particularly in the oil, gas, and petrochemical industries.

| EFW 309 Pipes | 6″ NB – 100″ NB |

| Schedule | SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS |

| Wall Thickness | Schedule 5S – Schedule XXS. |

| Length | Single Random, Double Random & Cut Length. |

| Specifications | ASTM A/ASME SA213/A249/A269/A312/A358 CL |

| Dimensions | ASTM, ASME and API |

| Size – Seamless 309 Pipes & Tubes | 1/2″ NB – 16″ NB |

| ERW 309 Pipes & Tubes | 1/2″ NB – 24″ NB |

| Types | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| End | Plain End, Beveled End, Treaded |

| Grade | Fe | Cr | Ni | Mn | Si | C | P | S |

| SS 309 | 60% | 23% | 14% | 2% | 1% | 0.20% | 0.045% | 0.030% |

| Yield Strength 0.2% Offset0 | Ultimate Tensile Strength | Elongation in 2 in. | Hardness | ||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 45,000 | 310 | 85,000 | 586 | 50 | 202 (HBN) |

Contact us to get a quick quote for your requirement.

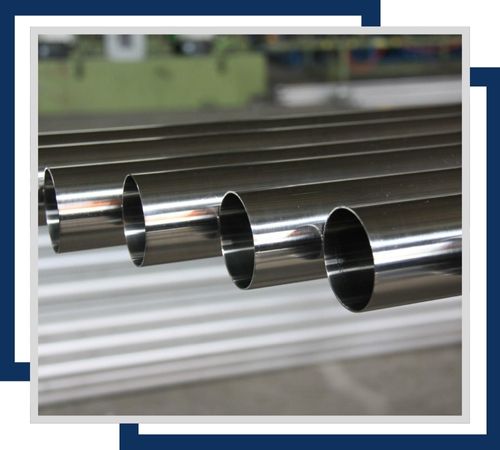

We offers high quality stainless steel 309 pipe, rigorously tested for durability and performance. Our products undergo extensive testing, including chemical composition, mechanical properties and corrosion resistance. Certified to industry standards, we ensure every pipe meets stringent quality standards, and provides reliable performance for a wide range of applications.

Stainless Steel 309 Seamless Pipe is a high-temperature alloy with excellent oxidation resistance, offering superior strength and durability in harsh environments. Ideal for aerospace and industrial applications

Stainless Steel 309 Welded Pipe provides excellent oxidation and corrosion resistance, suitable for high-temperature applications. Its welded construction offers cost efficiency and structural integrity in various industrial and aerospace uses.

Stainless Steel 309 ERW Pipe combines high-temperature resistance with exceptional durability. Its Electric Resistance Welded (ERW) construction ensures reliable performance in demanding environments, ideal for industrial and high-heat applications.

Stainless Steel TP 309 Seamless Pipes offer superior heat resistance and corrosion protection, ideal for high-temperature applications. Their seamless design ensures durability and reliability in industrial and aerospace environments.

Stainless Steel 309 Round Pipe features excellent heat resistance and corrosion resistance. Its round shape ensures versatility and strength, making it suitable for high-temperature industrial applications and structural uses.

Stainless Steel 309 EFW Pipe provides robust heat and corrosion resistance with Electric Fusion Welded construction. Ideal for high-temperature and industrial applications, it ensures durability and structural integrity.

These Stainless Steel 309 Bars find extensive use across various sectors due to their exceptional heat and corrosion resistance. In Dubai, UAE, they are mainly used in furnace components, heat exchangers, boilers, and chemical processing equipment. Their ability to endure high temperatures makes them ideal for refineries, power generation facilities, and thermal processing plants. Moreover, they are also utilized in food processing units and marine environments where hygiene and corrosion resistance are paramount. Their versatility, reliability, and long lifespan make them a top choice for demanding engineering applications.

©2024 Harshita Stainless All Rights Reserved.