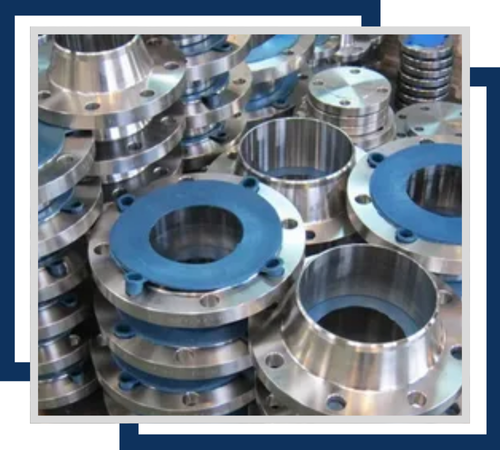

Stainless Steel 304L flanges are produced in Dubai and India to satisfy industries with corrosion-resistant, durable, and weldable piping fittings needs. SS 304L is the low-carbon form of 304 stainless steel with better resistance to intergranular corrosion after welding. The flanges are produced in slip-on, weld neck, blind, socket weld, and threaded types under ASTM A182 specifications. SS 304L flanges are extensively used in water treatment, food, chemical plants, and pharmaceutical systems. Due to their strength and rust resistance, they find application in pressure piping and sanitary installations requiring long term service.

SS 304L contains 18–20% chromium, 8–12% nickel, and ≤0.03% carbon. It has tensile strength of 485–620 MPa, yield strength of about 170–210 MPa, and 35% elongation. Its low carbon avoids carbide precipitation during welding, which ensures corrosion resistance in heat-affected zones. SS 304L flanges can be easily formed, welded, and maintained with good mechanical strength and long service life in oxidizing and mildly corrosive conditions.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class/Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304L | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We provides Stainless Steel 304L Flanges- Harshita Stainless,which has undergone intense testing to produce top quality and performance. The flange is thoroughly tested for meeting international standards and specifications. Products supplied by us are certified by recognized authorities for traceability and reliability in each batch. With modern technology and strict quality control, we ensure durability, corrosion resistance, and good mechanical properties. Harshita Stainless stands by the delivery of flanges with the highest level of industry standards in functionality and safety.

SS 304L slip-on flanges are widely used in piping systems due to their corrosion resistance and durability. Made from stainless steel 304L, these flanges provide reliable connections with ease of installation.

SS 304L weld neck flanges are designed for high-pressure applications, offering excellent strength and durability. Made from stainless steel 304L, they ensure a strong, leak-proof connection in critical piping systems.

SS 304L blind flanges are used to seal the end of a pipe, preventing flow and providing access for maintenance. Crafted from stainless steel 304L, they offer durability and corrosion resistance.

SS 304L socket weld flanges are designed for high-strength, secure connections in piping systems. Made from stainless steel 304L, they provide excellent resistance to corrosion and ease of installation.

SS 304L ring type joint flanges provide a robust seal for high-pressure applications. Made from stainless steel 304, they ensure a tight, leak-proof connection with their precision-engineered ring design.

SS 304L forged flanges are crafted from stainless steel 304L through a forging process, offering exceptional strength and durability. They are ideal for high-pressure applications and resist corrosion effectively.

SS 304L flanges are used extensively for piping system connections in water treatment, petrochemical plants, food and beverage plants, and pharmaceutical processing units. They can withstand corrosion and thermal expansion, so they are applied in steam lines, pressure vessels, and storage tanks. They provide effective sealing in both low-pressure and high-pressure applications. SS 304L flanges are particularly useful in systems that have to be welded and assembled repeatedly since they minimize the likelihood of intergranular attack. Their hygienic nature also makes them particularly suitable for use in CIP (clean-in-place) and SIP (sterilize-in-place) systems.

©2024 Harshita Stainless All Rights Reserved.