In Delhi, India, Harshita Stainless is a top producer and supplier of 304I stainless steel tubing, offering premium stainless steel products for commercial and industrial applications. 304I tubing is extensively utilised in chemical processing, food and beverage, and architectural applications due to its exceptional corrosion resistance, weldability, and durability. Harshita Stainless ensures accurate dimensions and long-lasting performance by using premium raw materials and cutting-edge technology in the production of this tubing. The company is a reliable source for stainless steel tubing needs because of its dedication to upholding strict quality standards, offering customised sizes, and providing prompt service both in India and abroad.

In order to improve its weldability and corrosion resistance, stainless steel 304I tubing, a low-carbon version of 304, normally has a reduced carbon content of ≤ 0.03%, 18–20% chromium, and 8–10.5% nickel. With an elongation of up to 40%, this austenitic stainless steel has a yield strength of 205 MPa and a tensile strength of about 515 MPa. It is perfect for fluid transportation and sanitary settings due to its mechanical stability, formability, and resistance to intergranular corrosion following welding. Reliable performance in a range of conditions is ensured by the tubing’s ability to maintain its integrity at both high and low temperatures.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 304L | S30400 | 1.4301 | SUS 304 | Z7CN18‐09 | 304S31 | 08Х18Н10 | X5CrNi18-10 |

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| N | – |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

Contact us to get a quick quote for your requirement.

We ensures the highest standards for our stainless steel 304I tubing through rigorous testing and certification processes. Each product undergoes extensive quality testing, including dimensional accuracy, tensile strength and corrosion resistance testing. We offer all relevant certifications, including material testing certificates (MTC) and compliance with international standards.

Stainless Steel 304I Seamless Tubing offers superior strength and corrosion resistance, ideal for high-pressure applications. Available in sizes ranging from 1/8” to 24” in diameter, it is crafted without any welded seams, ensuring durability and leak-proof performance.

Stainless Steel 304I Welded Tubing provides excellent resistance to corrosion and is cost-effective for less demanding applications. Typically available in sizes from 1/8” to 48” in diameter, it features welded seams and is suitable for a wide range of industrial uses.

Stainless Steel 304I Heat Exchanger Tube is designed for optimal thermal transfer and corrosion resistance in various heat exchanger systems. These tubes are available in sizes from 1/4” to 2” in diameter and are perfect for applications requiring efficient heat conduction.

Stainless Steel 304I Instrumentation Tubing is precision-made for high-pressure, high-purity, and corrosive environments. Available in sizes from 1/16” to 2” in diameter, it is ideal for instrumentation and control systems.

Stainless Steel 304I Boiler Tubes are engineered to withstand high temperatures and pressures in boiler applications. Ranging in sizes from 1/2” to 5” in diameter, they offer excellent resistance to oxidation and scaling.

Stainless Steel 304I U-Tubes are bent into a U-shape, perfect for heat exchangers and boiler applications where space efficiency and corrosion resistance are crucial. Sizes typically range from 1/4” to 2” in diameter, providing reliable performance in compact systems.

Stainless Steel 304I Condenser Tube is designed for high-efficiency heat exchange and corrosion resistance in condenser applications. These tubes come in sizes from 1/4” to 2” in diameter and are essential for maintaining system efficiency.

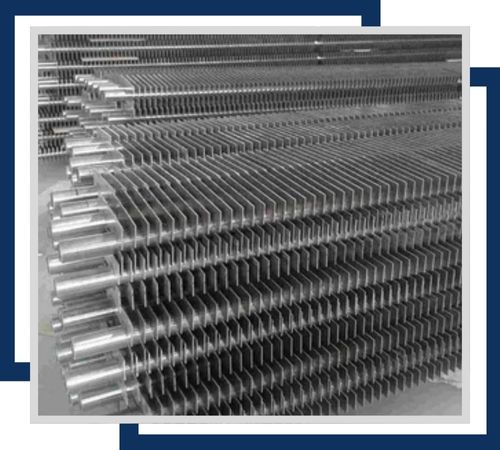

Stainless Steel 304I Fin Tubes feature extended surfaces (fins) to enhance heat transfer and corrosion resistance. Available in various diameters and fin configurations, they are ideal for applications needing increased heat dissipation.

Industries that need to transfer fluids in a sanitary and corrosion-resistant manner frequently use stainless steel 304I tubing. Food and beverage processing, dairy equipment, pharmaceutical manufacturing, chemical piping, and architectural structures are among the common uses. Because of its exceptional resistance to corrosion and ease of fabrication, it is also utilised in heat exchangers, condensers, and marine environments. The tubing is perfect for environments where intergranular corrosion must be kept to a minimum and for welding applications. Its clean finish, mechanical strength, and adaptability make it a preferred choice for industries demanding long-lasting, low-maintenance piping and structural solutions.

©2024 Harshita Stainless All Rights Reserved.