Home > Sheet and Plates > Stainless Steel 304H Sheet and Plates

Dubai and India produce Stainless Steel 304H sheet and plates for applications under high temperature and pressure. Grade 304H is a high-carbon variant of 304 stainless steel, which possesses enhanced strength and creep properties at high temperatures. These sheets and plates are produced according to ASTM A240 standards and are best suited to be used in power generation equipment, heat exchanger units, pressure vessel, and refinery equipment. With superior oxidation resistance and formability, SS 304H plates are suitable for welded constructions under higher service temperatures. They exhibit mechanical stability in terms of fluctuating thermal conditions.

18–20% chromium, 8–11% nickel and higher carbon content (0.04–0.10%) are present in SS 304H. This higher carbon content enhances high-temperature strength and creep resistance. It provides 520–720 MPa tensile strength, yield strength of about 210 MPa, and elongation of approximately 35%. SS 304H enjoys excellent corrosion resistance and oxidation stability in high-temperature use. It can be welded by applying normal methods and is immune to carbide precipitation due to long exposure to heat. Thus, it is for use in high-pressure and high-temperature environments needing long-term mechanical strength.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Sheet and Plate Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 10.5 | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

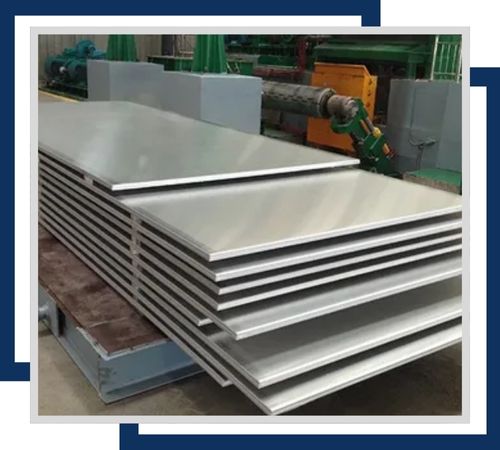

They come in dimensions ranging from 3mm up to 150mm thick, and up to 2000mm wide. Hot-rolled sheets are excellent in strength, ideal for structural applications.

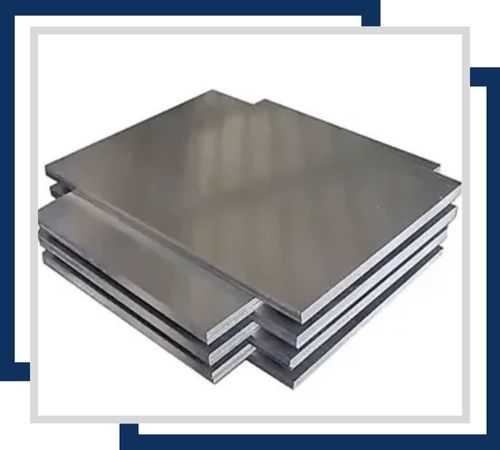

Cold-rolled sheets have a thickness of between 0.3mm to 6mm, and their widths can reach up to 1500mm. They can give a fine surface finish, as well as very accurate dimensioning, perfect for precision applications and fabrication.

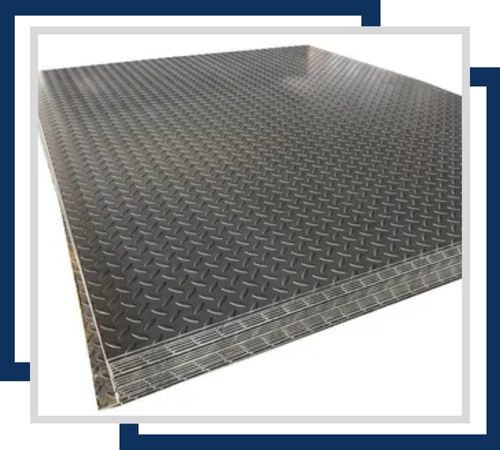

These sheets range from 1mm to 12mm in thickness. The texture on them is what gives them their anti-slip surface. They are mainly used in flooring and industrial platforms.

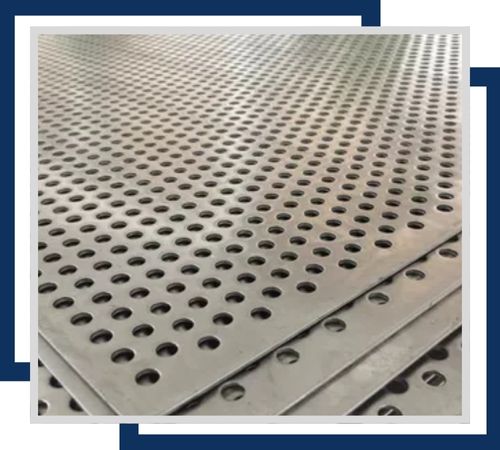

These sheets mainly range between 0.3mm and 12mm in thickness. Due to the uniform perforations, they are widely applied in applications such as filtration, ventilation, and decorative purposes.

The range in thicknesses for these thin sheets varies from 0.05mm to 3mm and finds applications in precise adjustments and alignment during a machinery component or structural component.

Polished sheets are available from a thickness of 0.3mm to 6mm, providing a reflective finish, and find applications in aesthetic applications and architectural designs.

Harshita Stainless offers an excellent customer experience with strong documentation for our premium Stainless Steel 304H Sheets and Plates. The necessary documents that accompany our product are commercial invoices, packing lists, fumigation certificates, heat treatment charts, quality assurance plans, and NABL-accredited lab test reports. These documents prove the authenticity and exceptional quality of our products, thereby building trust and confidence among our esteemed customers. In addition, we offer a variety of test certificates with our Stainless Steel 304H Sheets and Plates, including MTC according to EN 10204/3.1b, PMI Test Certificates, 100% radiography test reports, and Third Party Inspection Certificates. These accreditations emphasize our commitment to customer satisfaction and our relentless drive for excellence in product quality.

304H plates and sheets find extensive applications in boilers, heat exchangers, pressure piping, and superheater systems. Their increased carbon content enhances performance in thermal cycling applications and prolonged exposure to heat, including nuclear power plants, refinery heaters, and high-pressure steam piping. SS 304H finds application in structural supports, furnace parts, and exhaust systems. These plates are best welded into intricate assemblies that involve corrosion resistance as well as high-temperature mechanical strength. Their high temperature resistance and durability make for safe and efficient operation in energy-consuming, process-critical applications.

©2024 Harshita Stainless All Rights Reserved.