Harshita Stainless, a well-respected manufacturer and supplier located in Delhi, India, has made a name for itself in the stainless steel industry. With a strong focus on quality and innovation, this company has positioned itself as a top Stainless Steel 301 Tubing Manufacturer in Dubai, UAE. They cater to a wide range of industrial needs, providing precision-engineered tubing solutions that adhere to global standards. Thanks to their advanced manufacturing processes and rigorous quality checks, their products are known for their durability, corrosion resistance, and high performance. With a reputation for timely deliveries and a customer-first approach, Harshita Stainless is steadily expanding its footprint in international markets, especially in the UAE.

Stainless Steel 301 tubing is made up of chromium (16-18%), nickel (6-8%), along with trace amounts of carbon, manganese, silicon, and nitrogen. This unique blend gives it remarkable strength, good ductility, and impressive corrosion resistance. In terms of mechanical properties, it boasts a tensile strength ranging from about 520 MPa to 930 MPa and a yield strength of up to 275 MPa, depending on the tempering process. The tubing retains good toughness even in colder conditions and is easy to form or weld. These characteristics make SS 301 tubing an excellent choice for structural and dynamic applications, especially in demanding environments like those found in Dubai, UAE.

Tubing Specification : ASTM A312, A358 / ASME SA312, SA358

Dimension Standard : ANSI B36.19M, ANSI B36.10

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type : Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish : 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

| Grade | C | Ma | Si | Ph | Su | Ch | Ni | Nr |

| SS 301LN | 0.03max | 2.00max | 1.00max | 0.045max | 0.015max | 16.5-18.5 | 6.0-8.0 | 0.07-0.20 |

| Element | Tensile strength (Outokumpu typical, cold rolled strip/sheet; EN 10002-1) | Yield strength (@strain 0.200 %) | Elastic modulus | Poisson’s ratio | Elongation at break (in 50 mm) |

| Metric | 765 MPa | 350 MPa | 193 GPa | 0.300 | 47% |

| Imperial | 111000 psi | 50800 psi | 27992 ksi | 0.300 | 47% |

Contact us to get a quick quote for your requirement.

Harshita Stainless ensures the highest stainless steel 301 tubing standards through rigorous testing and certification programs. Extensive analyzes are performed on each formulation, including chemical composition analysis, mechanical property testing and validation theory. Certificates such as Mill Test Reports (MTR) and compliance with international standards have been issued to ensure product reliability and efficiency.

Known for its excellent corrosion resistance, Stainless Steel 301 Seamless Tubing is available in sizes ranging from 1/4 inch to 12 inches in diameter. It is typically used in structural applications due to its strength and durability.

Offering good corrosion resistance, Stainless Steel 301 Welded Tubing comes in sizes from 1/2 inch to 6 inches in diameter. It is produced by welding flat-rolled stainless steel and is commonly used in various industrial applications.

With robust corrosion resistance, Stainless Steel 301 Heat Exchanger Tubes are available in sizes from 1/4 inch to 2 inches in diameter. These tubes are designed for efficient heat transfer in heat exchangers.

This tubing provides high corrosion resistance and is available in diameters ranging from 1/8 inch to 2 inches. It is used in various instrumentation and control applications due to its precision and strength.

Featuring good corrosion resistance, Stainless Steel 301 Boiler Tubes come in sizes from 1 inch to 4 inches in diameter. They are utilized in boilers for steam and water applications due to their high thermal and mechanical properties.

Known for their corrosion resistance, Stainless Steel 301 U-Tubes are typically available in sizes from 1/2 inch to 2 inches in diameter. They are often used in heat exchangers and other applications requiring curved tubing.

Offering strong corrosion resistance, Stainless Steel 301 Condenser Tubes are available in diameters from 1/2 inch to 4 inches. They are designed for use in condenser units where high thermal efficiency and resistance to corrosion are critical.

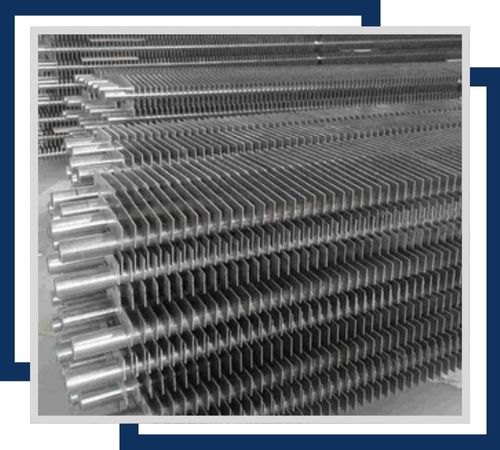

With excellent corrosion resistance, Stainless Steel 301 Fin Tubes are usually available in sizes from 1/2 inch to 2 inches in diameter. They are used in heat exchangers where increased surface area is required for heat transfer.

Due to its high strength, corrosion resistance, and excellent formability, Stainless Steel 301 tubing is widely utilized across various industries. In Dubai, UAE, it finds applications in automotive parts, aircraft components, architectural structures, and industrial equipment. It’s also well-suited for chemical processing, oil and gas pipelines, and food processing systems, where hygiene and durability are paramount. Its ability to endure high-pressure situations and extreme temperatures makes it perfect for construction, marine, and transportation sectors. Additionally, it’s a preferred choice for applications that require precision and longevity.

©2024 Harshita Stainless All Rights Reserved.