Located in Delhi, India, Harshita Stainless is a reputable and trustworthy manufacturer and supplier of 17-7 PH stainless steel tubing, providing top-notch tubing solutions for crucial engineering applications. Harshita Stainless uses advanced manufacturing techniques and premium materials to produce 17-7 PH tubing, which is well-known for its high strength, corrosion resistance, and exceptional fatigue performance. The automotive, chemical processing, marine, and aerospace industries all make extensive use of the tubing. Precision-engineered stainless steel tubing that meets the most exacting industry requirements is provided to both domestic and international clients by Harshita Stainless, which is dedicated to quality, on-time delivery, and customer satisfaction.

The precipitation-hardened stainless steel alloy known as Stainless Steel 17-7 PH Tubing is composed of 6.5–7.75% nickel, 0.75–1.5% aluminium, and 17–19% chromium. It offers exceptional mechanical qualities, such as yield strength of approximately 1170 MPa following heat treatment and tensile strength of up to 1310 MPa. In addition to having good formability and outstanding fatigue resistance, the alloy retains its mechanical strength and dimensional stability when heated. It performs exceptionally well in moderately corrosive environments and has corrosion resistance comparable to that of 304 stainless steel, particularly after hardening through ageing or heat treatment.

| Tensile Strength | 1100 MPa (160,000 psi) minimum |

| Yield Strength | 1035 MPa (150,000 psi) minimum |

| Elongation | 20% minimum |

| Hardness | HRC 40-47 (in Condition TH1050) |

| Element | Min | Max |

|---|---|---|

| Cr | 16 | 18 |

| Ni | 6.5 | 7.75 |

| Al | 0.75 | 1.5 |

| Mn | – | 1 |

| Si | – | 1 |

| C | – | 0.09 |

| P | – | 0.04 |

| S | – | 0.03 |

| Fe | Balance | |

Contact us to get a quick quote for your requirement.

We ensures the highest quality stainless steel 17-7 PH tubing through rigorous testing and certification processes. Our products undergo extensive technical, chemical and theoretical testing to meet international standards. We offer an extensive certification report, which guarantees excellent performance, authority and reliability, making us a trusted supplier in the industry.

Stainless Steel 17-7PH Seamless Tubing offers high strength and moderate corrosion resistance. Available in sizes ranging from 0.25″ to 2″ OD, it is ideal for aerospace and chemical processing applications. Its seamless construction ensures uniformity and integrity under pressure.

Stainless Steel 17-7PH Welded Tubing provides excellent formability and corrosion resistance. Sizes range from 0.5″ to 4″ OD, suitable for structural and mechanical uses. The welded seams are treated to enhance durability and prevent corrosion

Stainless Steel 17-7PH Heat Exchanger Tubes are designed for high-temperature environments, offering excellent corrosion resistance. Available in sizes from 0.5″ to 3″ OD, these tubes are crucial for efficient heat transfer in industrial processes. They are often used in power generation and petrochemical industries.

Stainless Steel 17-7PH Instrumentation Tubing ensures precision and high corrosion resistance. Typically available in sizes from 0.125″ to 1″ OD, it is perfect for sensitive instrumentation and control systems. Its stability under varying pressures makes it ideal for critical applications.

Stainless Steel 17-7PH Boiler Tubes are built to withstand high pressures and temperatures, with excellent corrosion resistance. Sizes range from 0.5″ to 5″ OD, making them suitable for power plants and industrial boilers. They ensure long-lasting performance under extreme conditions.

Stainless Steel 17-7PH U-Tubes offer great strength and corrosion resistance, ideal for heat exchangers and condensers. Available in sizes from 0.5″ to 2.5″ OD, these U-shaped tubes facilitate efficient thermal transfer. Their design allows for effective use in compact spaces

Stainless Steel 17-7PH Condenser Tubes are corrosion-resistant and highly durable, ideal for condensing heat in various systems. Sizes range from 0.5″ to 3″ OD, used extensively in HVAC and refrigeration industries. These tubes ensure efficient and reliable performance.

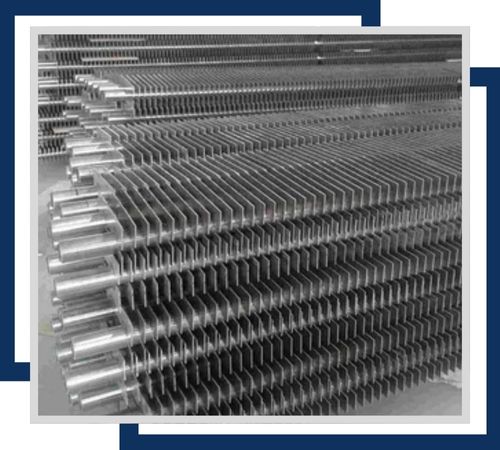

Stainless Steel 17-7PH Fin Tubes enhance heat transfer efficiency while providing excellent corrosion resistance. Available in sizes from 0.5″ to 3″ OD with various fin configurations, they are used in heat exchangers and cooling applications. The fins increase the surface area for better thermal performance.

High-performance applications needing exceptional strength, fatigue resistance, and moderate corrosion resistance frequently use stainless steel 17-7 PH tubing. It is frequently found in marine hardware, chemical processing equipment, springs, actuators, and aerospace components. Additionally, the tubing is perfect for use in precision instruments, nuclear reactors, and automotive systems where corrosion, deformation, and stress resistance are critical. It is appropriate for dynamic applications such as bellows, diaphragms, and structural tubing because it maintains its strength after heat treatment. 17-7 PH tubing provides a reliable solution for industries demanding long-lasting, high-strength, and corrosion-resistant materials.

©2024 Harshita Stainless All Rights Reserved.