Home > Sheet and Plates > SS 415 Sheet and Plates

Based in Delhi, India, Harshita Stainless is a reputable producer and supplier of stainless steel SS 415 sheets and plates. Harshita Stainless produces premium 415 stainless steel products that are perfect for applications requiring exceptional mechanical qualities and moderate corrosion resistance, with an emphasis on accuracy, strength, and quality. The martensitic stainless steel SS 415 is prized for its resilience to heat, hardness, and toughness. To guarantee dimensional accuracy and dependability, the business employs cutting-edge machinery and strict quality control procedures. Harshita Stainless, which serves a variety of industries in India and overseas, is dedicated to prompt delivery and total client satisfaction.

The typical composition of stainless steel SS 415 sheets and plates is 11.5–13.5% chromium and a higher carbon content (up to 0.15%), with trace amounts of silicon, phosphorus, and manganese. After heat treatment, SS 415, a martensitic grade, provides excellent strength and hardness. It offers good impact resistance, a yield strength of roughly 450–650 MPa, and a tensile strength of roughly 750–950 MPa. Though its corrosion resistance is moderate compared to austenitic grades, SS 415 excels in applications requiring wear resistance, strength, and mechanical performance in elevated temperatures and harsh environments.

| Specifications : | ASTM A240 / ASME SA240 |

| Dimensions : | ASTM, ASME and API |

| Standard : | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Surface : | 2B, 2D, BA, NO.4, NO.8, 8K, Mirror,Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Width : | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,etc. |

| Finish : | Black,Bright Polished,Rough Turned,No.4 Finish,Matt Finish,BA Finish |

| Length : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Grade | C | Mn | P | S | Si | Ch | Ni | Mo |

| SS 415 | 0.05 max | 0.50-1.00 | 0.030 max | 0.030 max | 0.60 max | 11.5-14.0 | 3.5-5.5 | 0.50-1.00 |

| Tensile Strength R₃ N/mm² | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 | 700-800 |

| 0.2% Offset Yield Strength Rᵖ ≥N/mm² | 520 | 520 | 520 | 520 | 520 | 520 | 520 |

| Elongation in 2 inches, % | 15 min | 15 min | 15 min | 15 min | 15 min | 15 min | 15 min |

| Grade | Density lbm/in3 | Melting Range(°F) | Thermal Conductivity(BTU-in/hr- ft. °F) | Electrical Resistivity(in x 10-6) | Modulus of Elasticity (psi x 106 | Coefficient of Thermal Expansion (in/in)/°F x 10-6 | Specific Heat(BTU/lb/°F) |

|---|---|---|---|---|---|---|---|

| 415 | -at 68°F: 0.280 | 2700 to 2790 | 187 at 212°F | 23.7 at 68°F | 29 | 6.0 at 32 – 212°F | 0.11 at 68°F to 212°F |

| – | – | – | – | – | 7.5 at 68 – 1200°F | – |

Contact us to get a quick quote for your requirement.

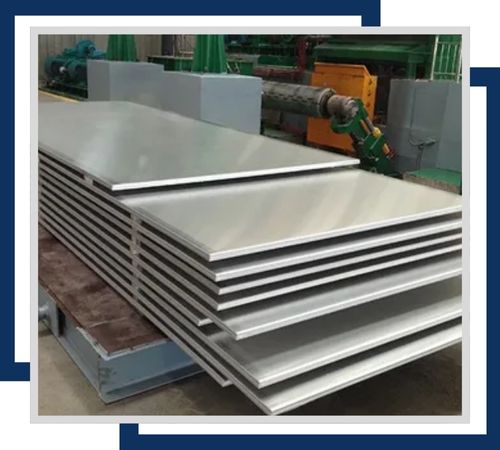

SS 415 Hot Rolled Sheets and Plates, as such, are specifically meant for making glorious strength, durability, and corrosion resistance from stainless steel. These are found in various sizes, with a range of 1.5mm to 80 mm of thickness, up to 2000mm widths to cater for various industrial applications.

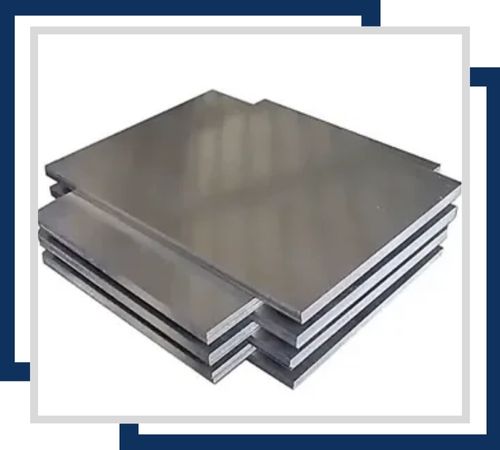

SS 415 Cold Rolled Sheets are stainless steel sheet with a bright surface finish, high strength, and excellent durability. Sheets available in various sizes between 0.3 mm to 3.0 mm thickness range and from 1000 mm to 2000 mm width with suitable applications.

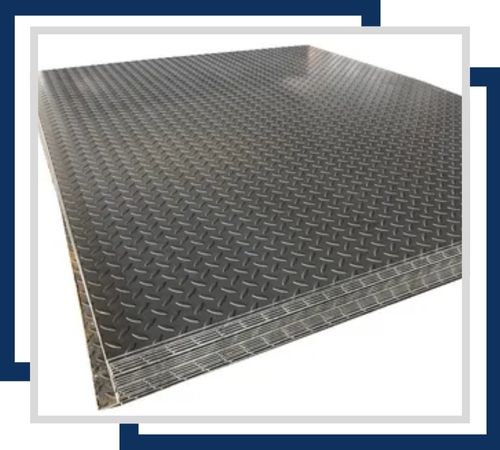

SS 415 chequered plates are stainless steel sheets with raised, textured patterns on them for maximum slip resistance and strength. It is available in various thicknesses and sizes, and it finds its application as a flooring or ramp material as well as an industrial application in the form of excellent corrosion resistance and aesthetic value.

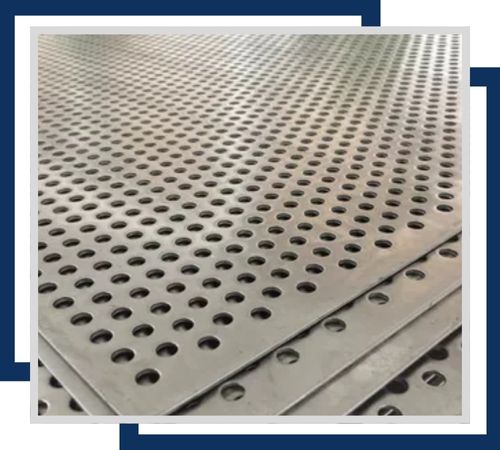

SS 415 perforated plates are of high-quality stainless steel sheets designed with precise holes to provide better ventilation, filtration, and strength. The plates can be available in a variety of sizes, with the standard being 4′ x 8′, or as custom sizes depending on the particular application in industries.

SS 415 Shim Sheets are precision engineered stainless steel sheets for industrial purposes. These have excellent corrosion resistance and strength with sizes ranging from 0.05mm to 5mm thickness and various lengths and widths, which can be customized according to the specific need.

SS 415 Polished Plates are stainless steel sheets of great quality, highly recognized for corrosion resistance, strength, and shine. The SS 415 plates vary in different sizes, normally in the thickness between 0.5mm and 50mm. The product is available in any length and width as per the needs of various industrial applications.

Harshita Stainless maintains a commitment for hassle-free experiences for our esteemed customers. Here, at this company, our high-quality SS 415 Sheet and Plates shall be offered completely documented to create a better buyer-seller market. Documents as commercial invoices, Packing lists, fumigation certificates, Heat Treatment Charts, QA plans, along with the Test Reports done with NABL approvals, these add value in maintaining the genuity and outstanding quality of products produced by this unit. In addition, we provide Stainless Steel 415 Sheets and Plates with various test certificates, such as MTC according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third Party Inspection Certificates, in order to prove our commitment to product excellence and customer satisfaction.

In the engineering and industrial sectors, stainless steel SS 415 sheets and plates are widely used because they are strong and resistant to wear. Applications include heavy-duty machine parts, bolts, turbine blades, fasteners, pump shafts, and valve components. These plates and sheets are perfect for uses where structural integrity and hardness are crucial, such as in mechanical manufacturing, petrochemical processing, and power generation. SS 415 plates are also utilised in defence and automotive components because of their excellent heat treatability and machinability. Although not ideal for highly corrosive environments, they perform well in dry or mildly corrosive industrial atmospheres.

©2024 Harshita Stainless All Rights Reserved.