Home > Sheet and Plates > SMO 254 Sheet and Plates

Harshita Stainless is a well-respected name in the stainless steel manufacturing and supply industry, based in Delhi, India. They take pride in being a top manufacturer of SMO 254 sheets and plates for clients in Dubai, UAE. With a strong focus on quality and innovation, the company provides high-performance products designed for critical industrial applications. Each sheet and plate from Harshita Stainless is crafted to meet international standards, ensuring durability, corrosion resistance, and outstanding strength. Thanks to their advanced manufacturing technology and a skilled team, they’ve earned a solid reputation for timely deliveries and customer satisfaction throughout the Middle East.

SMO 254 sheets and plates are made from a high-alloy austenitic stainless steel, featuring a chemical makeup of about 20% chromium, 18% nickel, 6% molybdenum, and nitrogen. This unique blend offers remarkable resistance to pitting and crevice corrosion. On the mechanical side, SMO 254 boasts a minimum tensile strength of 650 MPa and a yield strength of 300 MPa, along with impressive ductility and impact strength. These characteristics make it perfect for challenging environments like seawater or acidic conditions, ensuring reliable long-term performance in demanding industrial sectors.

| STANDARD | Stainless Steel 348H Sheet and Plate |

| EN | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| JIS | SUS 316L |

| BS | 316S11 / 316S13 |

| UNS | S31603 |

| WERKSTOFF NO. | 1.4404 / 1.4435 |

| AFNOR | Z7CND17‐11‐02 |

| GOST | 03Ch17N14M3 / 03Ch17N14M2 |

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

Contact us to get a quick quote for your requirement.

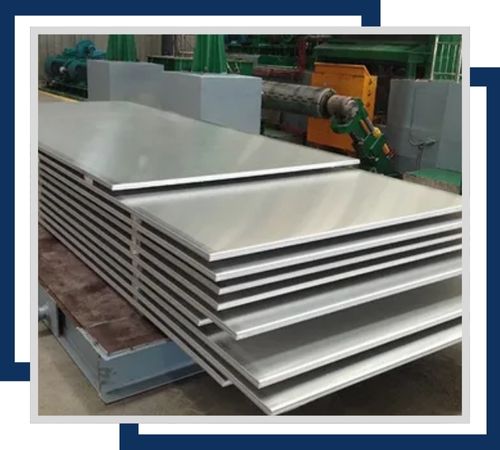

SMO 254 hot rolled plates have high strength and resistance to corrosion, and therefore, can be used for heavy-duty applications. The material is usually in a thickness range of 3mm to 50mm with width up to 2000 mm. It also comes in hot-rolled finish for strength and durability with the capability of sustaining high temperature and aggressive environment.

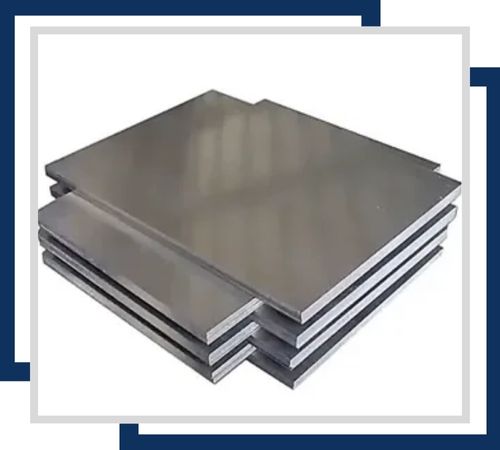

SMO 254 Cold Rolled Sheets provide a bright surface finish and excellent dimensional accuracy, with good corrosion resistance. These sheets are available in thickness from 0.5 mm up to 3 mm and widths up to 1250 mm. The strength of these sheets is improved by cold rolling, making them ideal for precision applications.

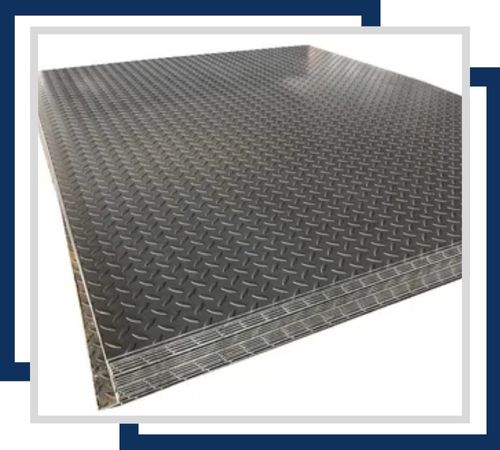

SMO 254 Chequered Plates offer an embossed pattern for increased slip resistance and longevity. Thickness options range from 3 mm to 12 mm, with a maximum width of 1500 mm. They are used as flooring in most industrial applications, offering great corrosion resistance.

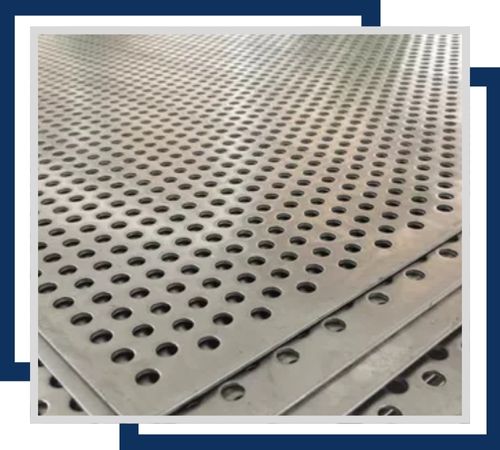

SMO 254 Perforated Sheets come in different perforation patterns depending on the design and functional requirements of the application. They are offered in thickness ranges from 1mm to 6mm and width up to 1200 mm. Due to their high resistance to corrosion, they are used both for decorative as well as industrial applications.

SMO 254 Shim sheets are used with a spacing or aligned application for variety of usages. Generally made available with widths up to 1000mm and a standard thickness between 0.1 mm and 1mm these shim sheets promise excellent corrosion resistivity under stringent conditions, performing well even during long exposure.

SMO 254 Polished Plates have high-quality reflective surfaces and are aesthetically pleasing along with corrosion resistant. They have a thickness from 2mm to 25mm and can be up to 1500mm in width. The architectural and decorative usage is possible by the polished surface.

Harshita Stainless commits to delivering the best seamless experience to our valued customers with extensive documentation on top-quality SMO 254 Sheets and Plates. We deliver to our clients, all necessary documents such as the commercial invoice, packing list, fumigation certificate, heat treatment chart, quality assurance plan, and NABL-approved lab test reports, all of which would ensure authenticity as well as superiority in our product offerings. In addition, test certificates, MTC according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third Party Inspection Certificate are supplied with our SMO 254 Sheets and Plates, which reveal our customer-oriented approach and a commitment to producing high-quality products.

Across various industries, SMO 254 sheets and plates are highly valued for their exceptional corrosion resistance and mechanical strength. In Dubai and throughout the UAE, they find extensive use in chemical processing, marine engineering, desalination plants, and offshore oil and gas platforms. Their ability to endure high temperatures and harsh chemical conditions makes them ideal for applications like heat exchangers, pressure vessels, and piping systems. Moreover, the food processing and pharmaceutical sectors utilize SMO 254 for equipment that requires hygienic and corrosion-resistant surfaces, ensuring safety and durability in critical applications.

©2024 Harshita Stainless All Rights Reserved.