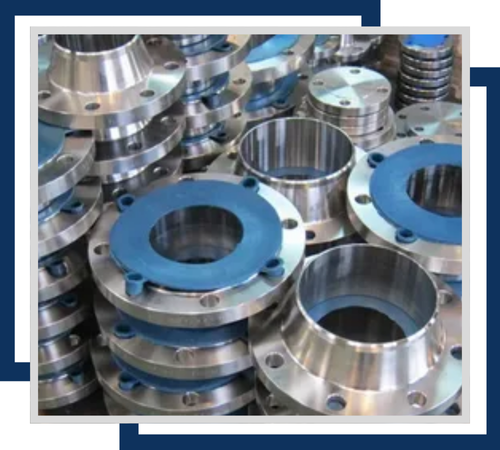

Harshita Stainless, a prominent manufacturer and supplier located in Delhi, India, has built a solid reputation for providing top-notch SMO 254 flanges to clients around the world, including in Dubai, UAE. With years of experience under their belt and a strong dedication to quality, this company focuses on crafting precision-engineered flanges that adhere to international standards. Harshita Stainless guarantees that each product boasts remarkable durability, corrosion resistance, and performance. Trusted by industries globally, they meet a variety of needs with prompt delivery and tailored solutions, making them a go-to choice for SMO 254 flange manufacturing and supply in the UAE and beyond.

SMO 254 flanges are made from high-alloy austenitic stainless steel, featuring a significant amount of molybdenum (6%), nitrogen, and chromium (20%), which boosts their corrosion resistance. On the mechanical side, these flanges deliver a tensile strength of about 650 MPa and a yield strength of 300 MPa, along with impressive elongation and impact toughness. Their superior pitting resistance equivalent number (PREN > 42.5) ensures they perform exceptionally well in chloride-rich environments, making them perfect for marine and chemical applications.

| Specifications | : | ASTM A182 / ASME SA182 |

| Size | : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc |

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 Flanges | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 |

Contact us to get a quick quote for your requirement.

The SMO 254 slip-on flanges are designed for high-performance applications, featuring superior corrosion resistance and strength. Ideal for harsh environments, they ensure reliable, leak-proof connections in demanding systems.

254 SMO weld neck flanges offer exceptional resistance to corrosion and high temperatures, making them ideal for challenging environments. Their robust design ensures strong, reliable connections in critical piping systems.

SMO UNS S31254 weld neck flanges are engineered for superior corrosion and heat resistance. Perfect for extreme conditions, they provide robust, dependable connections in high-stress and high-temperature environments.

254 SMO blind flanges are designed for high-corrosion resistance and strength in harsh environments. They effectively seal the end of a pipe, providing a secure, leak-proof closure in demanding applications.

SMO UNS S31254 blind flanges offer exceptional resistance to corrosion and high temperatures. Ideal for sealing pipe ends in challenging environments, they ensure a durable, leak-proof closure for critical systems.

SMO UNS S31254 orifice flanges are engineered for high durability and resistance to extreme conditions. They facilitate accurate flow measurement and control in corrosive and high-temperature environments, ensuring reliable performance.

We make sure the highest quality of our SMO 254 Flanges by conducting rigorous testing and inspections. Throughout the manufacturing process. These procedures guarantee the flanges durability and performance in challenging environments. Additionally we prioritize on time delivery to meet our customers deadlines. Ensuring seamless and reliable service for all orders.

These SMO 254 flanges are commonly used in situations that require high resistance to corrosion and extreme conditions. They find extensive application in offshore oil and gas platforms, desalination plants, pulp and paper processing, and the chemical manufacturing sector. They excel in seawater handling systems, flue gas cleaning, and heat exchangers, where strength and resistance to chloride stress corrosion cracking are crucial. The robust properties of SMO 254 also make it an excellent choice for pressure vessels and piping systems in demanding industrial settings, ensuring long-lasting performance and safety in critical operations.

©2024 Harshita Stainless All Rights Reserved.