Home > Electrodes > AWS Class ER309/309L SAW and FLUX

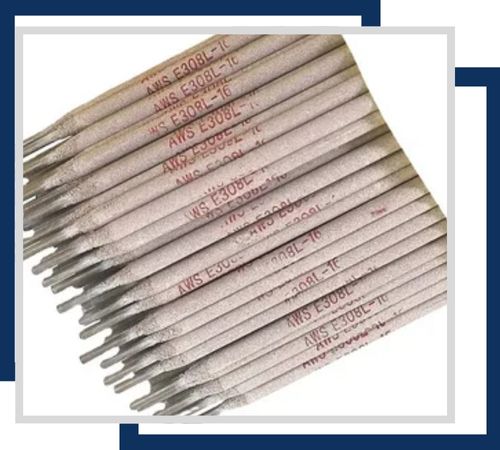

Harshita Stainless is one of the leading suppliers of AWS Class ER309/309L SAW and Flux from Delhi, India. Ideally suited for dissimilar metal welding and buffer layers, ER309/309L offers outstanding oxidation and heat scaling resistance. The low carbon “L“ grade minimizes the precipitation of carbides during welding to enhance intergranular corrosion resistance. Harshita‘s submerged arc welding consumables offer high strength, crack resistance, and cleanliness in bead formation. These products are suitable for the joining of stainless steel to carbon or low-alloy steels, and for overlaying surfaces which are exposed to high temperature and severe chemical conditions.

ER309/309L welding wire has a composition of 23–25% chromium and 12–14% nickel with a maximum of 0.03% carbon in the “L“ grade. This composition gives a strong, ductile weld deposit having good high-temperature strength and resistance to oxidation. Mechanical properties are tensile strength ≥80 ksi, yield strength ≥60 ksi, and elongation ≥30%. SAW flux provides stable arc control, smooth weld bead, and facile slag removal. ER309L has good hot crack resistance and is well suited for joining two dissimilar metals and as a buffer layer in high-temperature applications.

| Classification | AWS A5.9, ER309/309L |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS ER309/309L SAW & Flux Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.03 | 23.0-25.0 | 12.0-14.0 | 0.75 | 1.0-2.5 | 0.30-0.65 | 0.03 | 0.03 | 0.75 |

| Tensile Strength, kpsi: | 86* |

| Yield Strength, kpsi: | 58* |

| Elongation %: | 40* |

Contact us to get a quick quote for your requirement.

Alloy ER309/309L SAW and Flux are used for submerged arc welding of dissimilar metals and stainless steel, providing strong, corrosion-resistant welds with a clean, slag-free finish for various applications.

AWS A5.9 ER309/309L SAW and Flux Welding Wire is designed for submerged arc welding of dissimilar metals and stainless steel, offering strong welds, high corrosion resistance, and a clean, efficient finish.

AWS Class ER309/309L Submerged Arc Welding Flux ensures high-quality welds with excellent arc stability, minimal spatter, and a clean, slag-free finish, ideal for welding dissimilar metals and stainless steel.

We conduct rigorous in-house testing on our AWS Class ER309/309L SAW wire and flux to ensure optimal quality and performance. Our products undergo thorough inspections to meet industry standards, guaranteeing reliability and durability. With a focus on efficiency. We assure prompt delivery. To meet the needs of our clients without compromising on product excellence.

©2024 Harshita Stainless All Rights Reserved.