Home > Electrodes > AWS Class E410NiMo-16 Electrodes

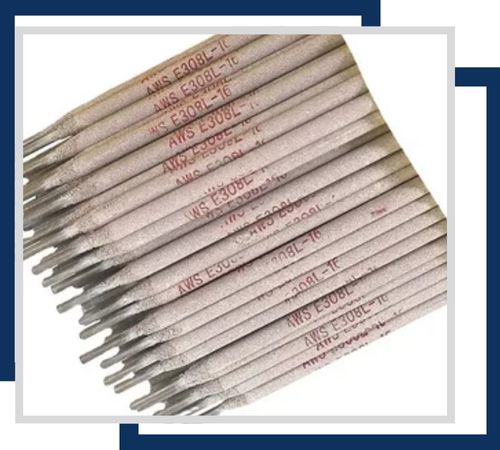

Harshita Stainless, a trusted manufacturer and supplier located in Delhi, India, specializes in top-quality AWS Class E410NiMo-16 Electrodes. These electrodes are specifically designed for welding martensitic stainless steels that demand high strength, toughness, and resistance to corrosion. With added nickel and molybdenum, they excel in challenging environments like seawater, chemicals, and high pressure. E410NiMo-16 electrodes provide excellent arc stability, a smooth weld bead finish, and minimal spatter, all while resisting cracking. Harshita Stainless guarantees that every batch meets international quality standards, making them perfect for power plants, marine structures, turbine components, pressure vessels, and chemical processing applications.

When it comes to composition and mechanical properties, AWS Class E410NiMo-16 Electrodes typically consist of 11.5–13.5% Chromium, 3.5–5.0% Nickel, 0.4–0.8% Molybdenum, and controlled carbon levels of about 0.03–0.06%. This combination enhances both corrosion resistance and mechanical strength. After air cooling or tempering, these electrodes develop a martensitic microstructure. They boast impressive mechanical properties, including a tensile strength of around 700–750 MPa, a yield strength of 500 MPa, and an elongation of 20–25%. Designed for DC+ polarity, they are particularly resistant to cracking, especially in weldments exposed to high stresses and corrosive conditions. To achieve the best hardness and toughness, post-weld heat treatment is generally recommended.

| Classification | AWS A5.4, E410NiMo-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E410NiMo-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.06 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 1.0 | 0.90 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance and are designed for applications requiring moderate to high tensile strength. They come in diameters ranging from 2.5 mm to 4.0 mm and lengths typically between 300 mm and 350 mm, making them ideal for thin-walled sections and precision welding.

Known for superior corrosion resistance, these electrodes are suitable for welding thicker sections and high-strength joints. Available in diameters from 3.2 mm to 5.0 mm and lengths of 300 mm to 400 mm, they are optimized for more demanding welding tasks requiring robust performance.

These electrodes have exceptional corrosion resistance and are ideal for shielded arc welding applications. They come in various diameters, including 2.5 mm, 3.2 mm, and 4.0 mm, with lengths of 300 mm to 400 mm, providing flexibility for various welding positions and joint configurations.

We provide the most extensive range of certifications with our AWS Class E410NiMo-16 Electrodes. In the package, we include commercial invoices, packaging lists, fumigation certificates, heat treatment charts, quality assurance plans and approved laboratory test reports. Further, we have several test certificates exclusively for the AWS Class E410NiMo-16 Electrodes. These certificates include MTC as per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. We intend to ensure 100% client satisfaction and confidence in our products by providing these comprehensive certifications.

AWS Class E410NiMo-16 Electrodes find extensive use in welding high-strength martensitic stainless steels like 410, 410NiMo, and similar alloys. Their superior corrosion resistance and mechanical strength make them ideal for applications such as hydroelectric turbines, valves, pump shafts, pressure vessels, heat exchangers, and equipment in chemical plants. Additionally, these electrodes are commonly employed in marine and offshore structures, ensuring durability and reliability in demanding environments.

©2024 Harshita Stainless All Rights Reserved.