Home > Sheet and Plates > Stainless Steel 301 Sheet and Plates

Harshita Stainless, a prominent manufacturer and supplier located in Delhi, India, has made a name for itself by providing top-notch stainless steel products to customers around the globe. We take pride in our expertise in crafting Stainless Steel 301 Sheets and Plates, serving clients in Dubai, UAE, with dedication. Our focus on excellence, precision engineering, and the use of high-quality raw materials guarantees outstanding durability and performance. By employing cutting-edge production methods and keeping our customers at the heart of what we do, we cater to a wide range of industrial needs in international markets. Harshita Stainless is committed to building trust through timely deliveries, competitive pricing, and customized solutions that adapt to the ever-changing demands of the stainless steel industry.

Stainless Steel 301 Sheets and Plates are primarily made up of chromium (16–18%), nickel (6–8%), and a low carbon content, which gives them remarkable corrosion resistance and strength. This type of austenitic stainless steel is known for its excellent formability and ductility. Its mechanical properties boast a tensile strength of up to 750 MPa, a yield strength of around 205 MPa, and increased hardness with cold working. These features make it perfect for applications that require both high strength and moderate corrosion resistance. SS 301 is also recognized for its impressive fatigue strength, making it a dependable choice for both structural and decorative uses.

| Item | Stainless Steel 301 sheet(Hot rolled, cold rolled) | |

| Thickness | 0.3~10.0mm | |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc | |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc | |

| Surface | the surface and finish of stainless steel 301 sheet: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | |

| Brand: | Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan Origin | |

| Package | Shrink-wrapped ,Carton boxes,Wooden pallets,Wooden boxes ,Wooden crates Etc. required. |

|

Element |

Percent by Weight |

|

|

Type 301 ANN |

||

|

Carbon |

0.150 maximum |

|

|

Manganese |

2.000 maximum |

|

|

Phosphorus |

0.045 maximum |

|

|

Sulfur |

0.030 maximum |

|

|

Silicon |

1.00 maximum |

|

|

Chromium |

16.00 – 18.00 |

|

|

Nickel |

6.000 – 8.000 |

|

|

Nitrogen |

0.10 maximum |

Contact us to get a quick quote for your requirement.

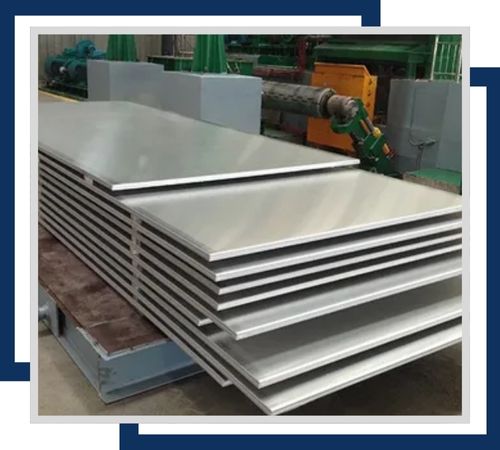

The sheets have moderate corrosion resistance, produced by high temperature rolling. They are typically available from thickness ranging from 3mm to 12mm with widths up to 2000mm and are applicable for structural applications requiring good toughness.

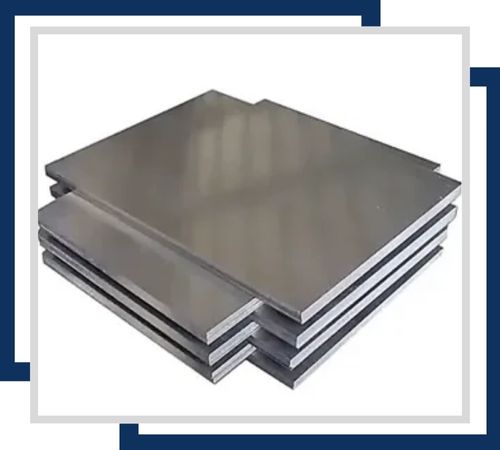

The superior corrosion resistance is provided by cold rolled plates, which are processed at room temperature, thus offering a smooth surface and precise thickness. The common dimensions are from 0.5mm to 6mm in thickness and widths up to 1500mm. They are suitable for high-precision applications.

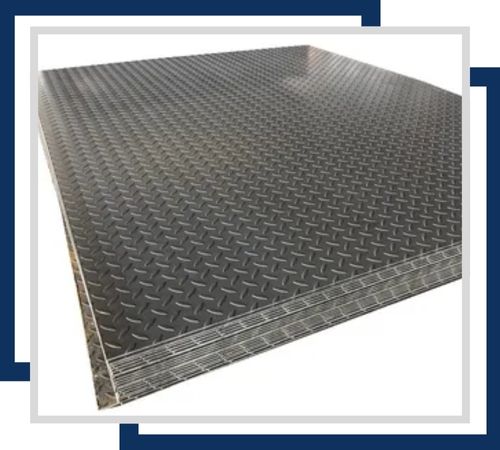

These plates come with a textured surface to have grip and last longer. They come in a thickness range that is between 1.5mm and 5mm and sizes that are standard are 1000mm x 2000mm. It is suitable for flooring and anti-slip application.

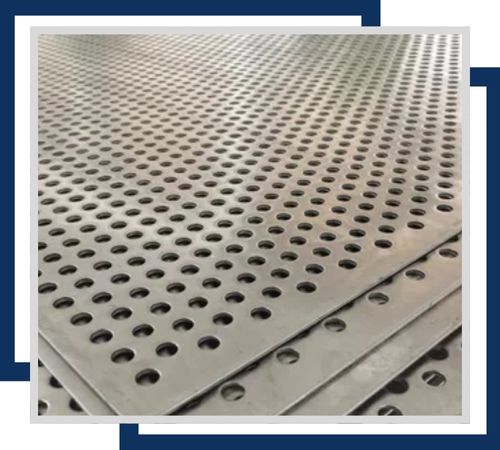

With good corrosion resistance, perforated sheets feature holes punched in various patterns, enhancing aesthetics and ventilation. Sizes usually range from 0.8mm to 3mm in thickness and can be customized up to 1500mm widths and used for filtration and decorative purposes.

Thin sheets with excellent corrosion resistance, often used to fill gaps or adjust clearances in machinery. These are available from 0.1mm up to 1mm in thickness and in standard sizes of 1000mm x 2000mm. Useful for precision alignment.

Polished plates are excellent for aesthetic applications and offer high corrosion resistance with a high gloss finish. Common thicknesses range from 1mm to 10mm, and sizes typically run to 1500mm x 3000mm. They are also used in architectural and decorative projects.

Harshita Stainless is devoted to providing excellent customer experience accompanied with complete documentation of our excellent-quality Stainless Steel 301 Sheets and Plates. We provide such critical documents such as a commercial invoice, a packing list, fumigation certificate, heat treatment chart, quality assurance plan, and NABL-approved lab test report. This set of documentation works to further endorse the legitimacy and high-grade of our product in the hands of our esteemed clients. On top of this, we provide the different test certificates – MTC according to EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third Party Inspection Certificate – for Stainless Steel 301 Sheets and Plates. All these test certificates would reflect our whole focus on customer-focused practices and will go on striving for excellence in product quality.

Stainless Steel 301 Sheets and Plates find their way into a variety of industries thanks to their exceptional strength, corrosion resistance, and formability. In Dubai, UAE, they are frequently used in construction, automotive, aerospace, and architectural fields. These sheets are perfect for creating structural components, panels, brackets, and trims. Moreover, they are utilized in railway cars, appliances, and industrial equipment where high strength and flexibility are crucial. Their ability to endure harsh environments and mechanical stress makes them a favored option for marine and coastal applications, ensuring durability and optimal performance even in challenging conditions.

©2024 Harshita Stainless All Rights Reserved.