Harshita Stainless, a prominent stainless steel manufacturer and supplier located in Delhi, India, specializes in high-performance Stainless Steel 348 Bars designed for critical industrial applications. These bars are celebrated for their remarkable resistance to intergranular corrosion, impressive high-temperature stability, and outstanding weldability. Harshita Stainless produces SS 348 bars in a variety of sizes and specifications to align with global standards and cater to specific client requirements. With a strong focus on quality, precision, and timely delivery, the company supports a diverse range of industries, including chemical processing, aerospace, power generation, and petrochemicals. Harshita Stainless guarantees reliable performance and durability in challenging operating conditions, both at home and abroad.

Stainless Steel 348 bars are a stabilized austenitic stainless steel alloy that contains 17–20% chromium, 9–13% nickel, and niobium (columbium) to inhibit carbide precipitation. This unique composition significantly boosts resistance to intergranular corrosion, particularly after welding. SS 348 bars boast a tensile strength of about 515 MPa, a yield strength of roughly 205 MPa, and impressive elongation of around 35%. Their Brinell hardness falls between 150–200 HB. These bars maintain their strength and structural integrity even at elevated temperatures, provide good creep resistance, and are non-magnetic when annealed. They also demonstrate excellent formability and toughness.

Element | Content (%) |

Iron, Fe | 60 |

Chromium, Cr | 23 |

Nickel, Ni | 14 |

Manganese, Mn | 2 |

Silicon, Si | 1 |

Carbon, C | 0.20 |

Phosphorous, P | 0.045 |

Sulfur, S | 0.030 |

Properties | Metric | Imperial |

Tensile strength | 620 MPa | 89900 psi |

Yield strength (@ strain 0.200%) | 310 MPa | 45000 psi |

Izod impact | 120 – 165 J | 88.5 – 122 ft-lb |

Shear modulus (typical for steel) | 77 GPa | 11200 ksi |

Elastic modulus | 200 GPa | 29008 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Elongation at break (in 50 mm) | 45% | 45% |

Hardness, Brinell | 147 | 147 |

Hardness, Rockwell B | 85 | 85 |

Hardness, Vickers (converted from Rockwell B hardness) | 169 | 169 |

Contact us to get a quick quote for your requirement.

We ensures the highest quality of stainless steel 348 tiles through rigorous testing and certification. Each product is subjected to non-destructive testing, technical analysis and chemical composition certification. Accredited to international standards including ASTM and ISO, our timbers provide exceptional reliability, corrosion resistance and performance for a variety of industrial applications.

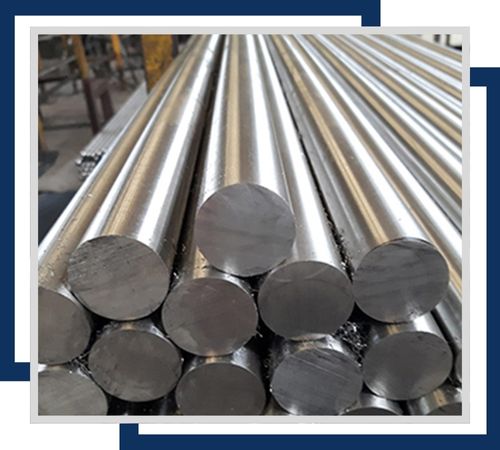

Corrosion-resistant and designed for high-temperature stability, Stainless Steel 348 Round Bars are available in diameters from 0.5″ to 12″. Ideal for use in aerospace components and chemical processing equipment where strength and durability are crucial.

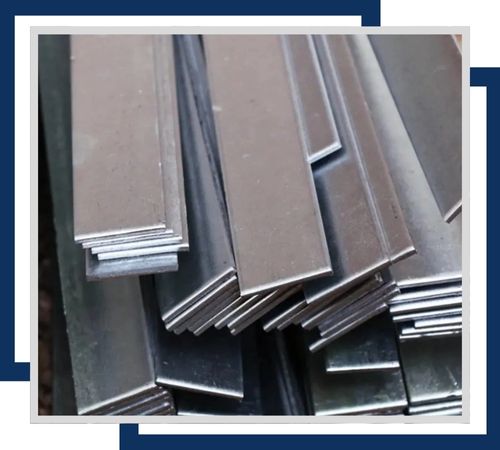

Stainless Steel 348 Flat Bars offer exceptional resistance to high temperatures, available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural and industrial applications requiring durability and resistance to oxidation.

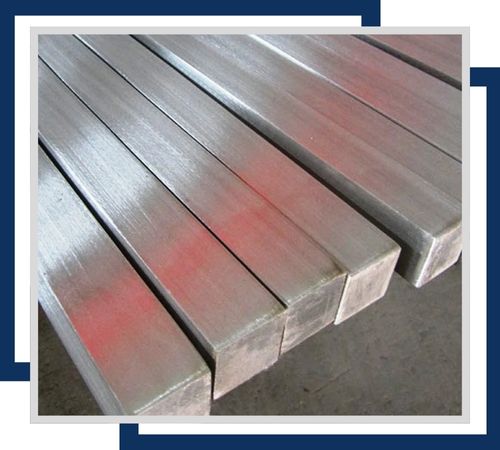

Corrosion-resistant Stainless Steel 348 Square Bars come in sizes from 0.5″ to 6″ on each side. These bars are designed for applications where high strength and resistance to extreme temperatures are necessary.

Offering excellent high-temperature resistance, Stainless Steel 348 Rectangular Bars are available in dimensions from 0.5″ x 1″ to 6″ x 12″. Suitable for heavy-duty applications requiring durability and resistance to oxidation.

Stainless Steel 348 Hexagonal Bars provide superior resistance to high temperatures, available in sizes from 0.5″ to 4″ across flats. Ideal for aerospace and chemical industries where robust performance is required.

Corrosion-resistant Stainless Steel 348 T-Bars come in dimensions from 0.5″ x 0.5″ to 6″ x 6″. Suitable for structural support and high-temperature applications where strength and durability are essential.

Stainless Steel 348 bars find extensive use in high-temperature and corrosive settings due to their exceptional stability, weldability, and resistance to intergranular corrosion. They are frequently employed in heat exchangers, reactor vessels, chemical processing equipment, and piping systems within petrochemical facilities. In the aerospace sector, SS 348 bars are utilized in exhaust systems, jet engine components, and various other parts.

©2024 Harshita Stainless All Rights Reserved.