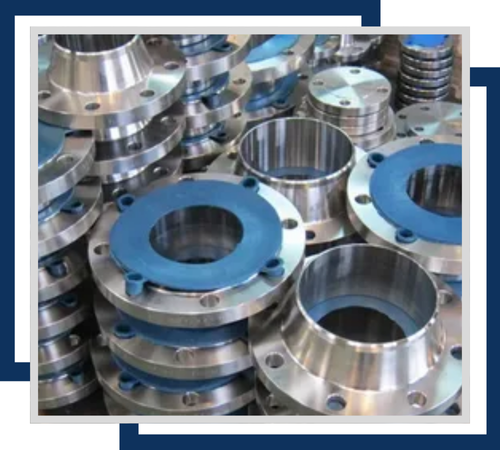

Manufacturers in Dubai and India produce Stainless Steel 321 flanges for high-temperature and corrosive environments. Grade 321 is a titanium-stabilized austenitic stainless steel that prevents intergranular corrosion and maintains its mechanical properties during thermal cycling. These flanges are available in slip-on, weld neck, blind, socket weld, and threaded types, meeting ASTM A182 and ASME B16.5 standards. They are used in pressure vessels, chemical processing, and heat exchangers, providing secure, leak-proof joints. With great weldability, formability, and precise dimensions, manufacturers ensure delivery with test certifications and export-ready packaging for industrial and offshore projects.

SS 321 contains 17–19% chromium, 9–12% nickel, and titanium at a minimum of five times the carbon percentage, which is typically ≤0.08%. It has a tensile strength of 515–620 MPa, a yield strength of around 205 MPa, and about 35% elongation. The addition of titanium stops chromium carbide from forming during welding, which helps maintain corrosion resistance. 321 holds onto its strength and oxidation resistance at temperatures up to 870°C. It also has excellent creep strength and resists stress rupture during prolonged heating. These properties make SS 321 flanges well-suited for high-temperature pressure systems and piping applications.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B 16.47 A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class/Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We offers the best quality Stainless Steel 321 Flanges Harshita Stainless,which has undergone intense testing to produce top quality and performance. The flange is thoroughly tested for meeting international standards and specifications. Products supplied by us are certified by recognized authorities for traceability and reliability in each batch. With modern technology and strict quality control, we ensure durability, corrosion resistance, and good mechanical properties. Harshita Stainless stands by the delivery of flanges with the highest level of industry standards in functionality and safety.

SS 321 slip-on flanges are designed for high-temperature and corrosion-resistant applications. Made from stainless steel, they provide reliable connections in piping systems, offering ease of installation and durability.

SS 321 weld neck flanges are engineered for high-stress applications, providing strong, reliable connections in piping systems. Crafted from stainless steel, they offer excellent resistance to high temperatures and corrosion.

SS 321 socket weld flanges are ideal for high-pressure and high-temperature applications. Made from stainless steel, they offer strong, reliable connections with ease of installation and excellent resistance to corrosion.

SS 321 blind flanges are used to seal the end of a piping system. Crafted from stainless steel, they provide a robust, corrosion-resistant solution for maintaining system integrity and pressure.

SS 321 ring type joint flanges offer a secure, leak-proof seal in high-pressure environments. Made from stainless steel, they feature a ring groove design for reliable, corrosion-resistant performance in demanding applications.

SS 321 forged flanges are crafted from stainless steel for high strength and durability. They are ideal for demanding applications, offering excellent resistance to high temperatures, corrosion, and mechanical stress.

Stainless Steel 321 flanges are commonly found in chemical plants, thermal power stations, refineries, marine exhaust systems, and heat exchangers. Their capability to resist carbide precipitation makes them a good fit for welded piping systems operating above 500°C. You can find them in steam lines, furnace ducts, oil processing lines, and catalytic converters. These flanges provide reliable sealing for high-pressure, high-temperature pipelines and equipment. Due to their strength and weldability, 321 flanges are also used in aerospace engine components and high-temperature refinery tubing. Manufacturers in Dubai and India meet the domestic and international demand for durable flanges with tight dimensional tolerances.

©2024 Harshita Stainless All Rights Reserved.