Harshita Stainless, located in Delhi, India, has built a solid reputation for manufacturing and supplying top-notch stainless steel products. One of our standout offerings is the Stainless Steel 455 Bar, celebrated for its remarkable strength, resistance to corrosion, and outstanding heat treatment capabilities. We produce SS 455 Bars that adhere to rigorous international quality standards, making them perfect for challenging engineering and industrial tasks. With our advanced manufacturing techniques, skilled team, and strict quality checks, we guarantee consistent performance and reliability. At Harshita Stainless, we’re committed to providing high-quality products along with timely delivery and personalized customer support, both in India and internationally.

Stainless Steel 455 Bars are a type of precipitation-hardening martensitic stainless steel that includes chromium (11–12%), nickel (7–9.5%), titanium (0.8–1.4%), and molybdenum (0.5%). This special blend gives the bars impressive strength and hardness after heat treatment. SS 455 boasts a tensile strength of up to 1380 MPa and excellent yield strength, making it a great choice for structural applications. It also offers moderate corrosion resistance, along with superior toughness and fatigue strength. The bar can be easily hardened through a straightforward heat treatment process, providing versatility for manufacturing and engineering sectors that need robust and durable materials.

| Dimension : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Grade : | Custom 455 (UNS No. S45500) Round Bars |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Surface : | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Application : | Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining |

| Condition : | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished. |

| Grade | C | Mn | Si | Ni | Cr | Ti | Mo | Cb+Ta | Cu |

| Custom 455 | 0.05 max | .50 max | .50 max | 7.50 – 9.50 | 11.00 – 12.50 | .80 – 1.40 | .50 | .10 – .50 | 1.50 – 2.50 |

| Material | Condition | 0.2 % Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | Notch Tensile Strength | % Elongation in 4D | % Reduction of Area | Rockwell C Hardness | Charpy V Notch Impact Strength (ft-lbs) |

| Alloy 455 Bar 1″ Section Custom 455® | A | 793 | 1000 | 1585 | 14 | 60 | 31 | 70 |

| Alloy 455 Bar 1″ Section Custom 455® | H900 | 1689 | 1724 | 1792 | 10 | 45 | 49 | 9 |

| Alloy 455 Bar 1″ Section Custom 455® | H950 | 1551 | 1620 | 2068 | 12 | 50 | 48 | 14 |

| Alloy 455 Bar 1″ Section Custom 455® | H1000 | 1379 | 1448 | 2000 | 14 | 55 | 45 | 20 |

| Alloy 455 Bar 1″ Section Custom 455® | H1050 | 1207 | 1310 | 1793 | 15 | 55 | 40 | 35 |

Contact us to get a quick quote for your requirement.

We prioritize quality assurance through a certification program that involves rigorous testing of our Stainless Steel 455 Bars. Each strip is thoroughly inspected for equipment, corrosion resistance and shape accuracy. Our products are certified to international standards, ensuring reliability and performance in a wide range of industrial applications.

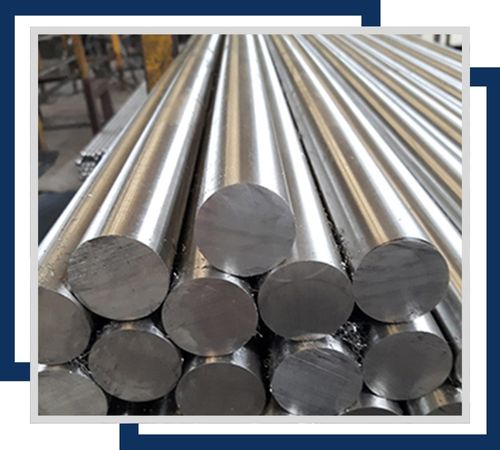

SS 455 Bar Round Bar is a high-performance stainless steel alloy known for its excellent resistance to corrosion and high strength. It offers good weldability and is commonly used in industries like aerospace, chemical, and petrochemical. The round bar form provides versatility for various machining applications, ensuring durability and reliability in harsh environments.

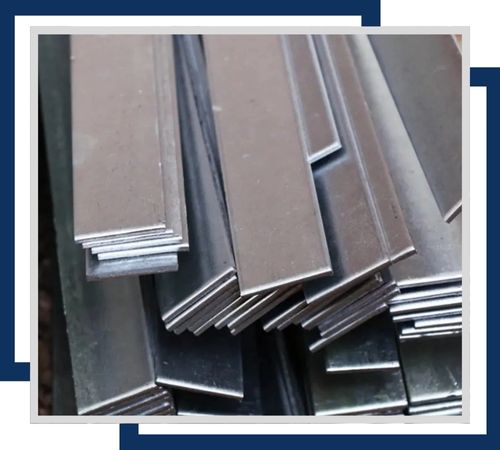

Stainless Steel 455 Flat Bar is a corrosion-resistant alloy with high strength and durability. It offers excellent resistance to pitting, stress, and oxidation, making it suitable for demanding applications in industries such as aerospace, automotive, and chemical processing. The flat bar shape allows for easy machining and fabrication.

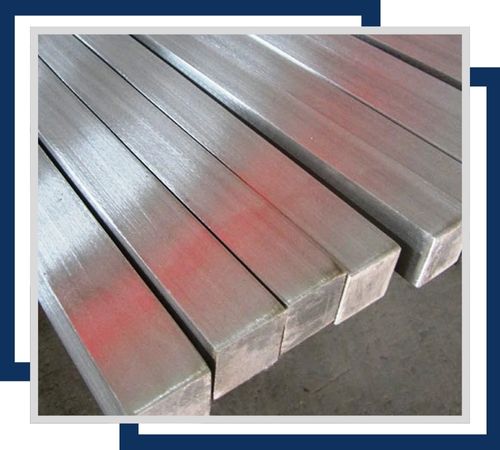

SS 455 Bar Square Bar is a high-strength stainless steel known for its excellent corrosion resistance, particularly in harsh environments. It offers good weldability and durability, making it ideal for applications in industries like aerospace, chemical processing, and manufacturing. Its square shape provides versatility for machining and fabrication.

Stainless Steel 455 Rectangular Bar is a corrosion-resistant alloy known for its high strength, excellent durability, and resistance to oxidation and pitting. It is ideal for demanding environments like aerospace, chemical processing, and marine industries. The rectangular shape allows for easy machining, making it suitable for various fabrication applications.

SS 455 Bar Hexagonal Bar is a high-strength stainless steel with excellent corrosion resistance, making it suitable for harsh environments. Its hexagonal shape provides enhanced grip for various industrial applications, including aerospace, chemical processing, and automotive. It offers good machinability, durability, and reliability for critical manufacturing and fabrication needs.

SS 455 Bar T-Bar is a high-performance stainless steel known for its excellent corrosion resistance and strength. The T-shaped profile provides increased structural support, making it ideal for use in demanding applications like aerospace, chemical processing, and construction. It offers durability, weldability, and ease of machining for various projects.

Stainless Steel 455 Bars find extensive use in industries like aerospace, defense, chemical processing, and high-stress engineering applications. Thanks to their excellent strength-to-weight ratio and good corrosion resistance, they’re perfect for crafting aircraft structural components, turbine parts, and high-performance automotive components. Their ability to withstand heat treatment and resist fatigue also makes them suitable for shafts, fasteners, gears, and other load-bearing elements. Additionally, SS 455 Bars are utilized in surgical instruments and marine hardware, showcasing their versatility across various demanding applications.

©2024 Harshita Stainless All Rights Reserved.