The stainless steel grades used in the manufacture of slitting coils include 304, 304L, 316, and 201 with chromium (16–20%) and nickel (8–12%) content. The material has tensile strength of 500–750 MPa, yield strength of 200–300 MPa, and good ductility. Our coils have superior surface finish, corrosion resistance, and formability. Mechanical integrity is preserved in the slitting process, and there are tight width tolerances, such that these coils are best suited for automated fabrication processes.

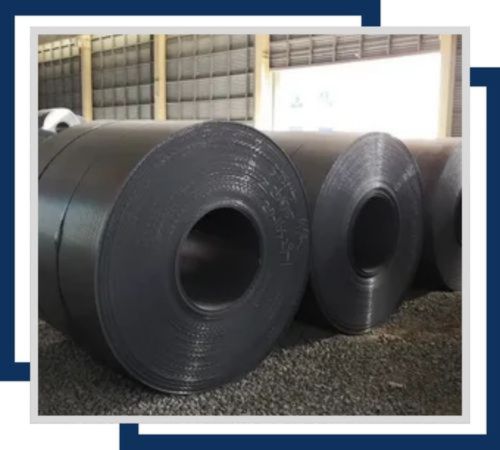

Stainless steel slitting coils offer excellent durability, high tensile strength, and remarkable corrosion resistance, making them ideal for various industrial applications. Their precision cutting ensures minimal material waste and enhanced dimensional accuracy. These coils are highly versatile, suitable for automotive, construction, and appliance manufacturing. They maintain structural integrity under extreme temperatures and resist oxidation and staining, ensuring long-term performance and reliability. Additionally, their aesthetic appeal and ease of maintenance make them a preferred choice for both functional and decorative uses.

Standard : ASTM A240, ASME SA240

Thickness : 0.2 mm – 16 mm

Width : 12 mm – 2000 mm

Length : In coil form

Finishes : No.1 (HR), 2B, 2D, BA, NO.1, NO.4, NO.8

Item : Stainless Steel Slitting Coils (Hot rolled, cold rolled), polish, finish, Bright Annealed

| Grade | Cr | Mn | Si | Ni | C | P | S | Fe |

| SS 410 | 11.50 – 13.50 | 0.0 – 1.50 | 0.0 – 1.00 | 0.0 – 0.75 | 0.08 – 0.15 | 0.0 – 0.04 | 0.0 – 0.02 | Balance |

| Tensile Strength Ksi (Mpa) | 0.2% Offset Yield Strength Ksi (Mpa) | Elongation, % in 2″ (51 mm) | Hardening Response HRC | HRB |

| 65 (450) – 74 (510) | 30 (205) – 42 (290) | 20 – 34 | 38-45 | 82-96 |

Contact us to get a quick quote for your requirement.

Stainless steel slitted coils are precision-cut strips of stainless steel used in manufacturing. They offer high corrosion resistance, durability, and are commonly used in automotive, construction, and appliance industries.

Cold rolled slitted coils are steel strips processed at room temperature, offering improved surface finish, tight tolerances, and increased strength, widely used in automotive, electronics, and appliance manufacturing.

No.1 finished slitted coils are stainless steel strips with a rough, dull finish achieved through hot rolling and annealing, typically used in industrial applications where surface smoothness is not critical.

2B finished slitted coils are stainless steel strips with a smooth, reflective surface achieved through cold rolling, annealing, and descaling, ideal for applications requiring aesthetic appeal and corrosion resistance.

Yes, stainless steel slitting coils can be welded using techniques like TIG, MIG, or spot welding. Proper preparation, filler material selection, and heat control are essential for optimal results.

Yes, stainless steel slitting coils are suitable for natural gas applications due to their excellent corrosion resistance, durability, and ability to withstand high pressures and varying temperatures.

Yes, stainless steel slitting coils are ideal for hygienic and sanitary applications due to their non-reactive surface, corrosion resistance, and ease of cleaning, ensuring compliance with strict hygiene standards.

Yes, stainless steel slitting coils can be used for underground applications, offering excellent corrosion resistance, durability, and strength. Proper coating or protection may be required for long-term performance in harsh environments.

Stainless steel slitting coils find applications in the automotive, electrical, HVAC, and consumer goods industries. They are apt for producing brackets, clamps, flexible hoses, cable trays, and architectural trims. They are applied in the refrigerators, dishwashers, and microwave liners of the appliance sector. Slitting coils facilitate efficient roll forming and stamping operations. Harshita Stainless provides slitting coils to Delhi and India, catering to customers requiring accuracy, durability, and visual appeal in high-volume production settings.

©2024 Harshita Stainless All Rights Reserved.