Home > Stainless Steel 304/304L Channels

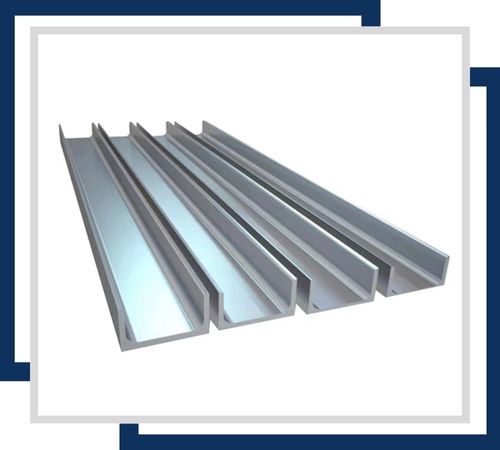

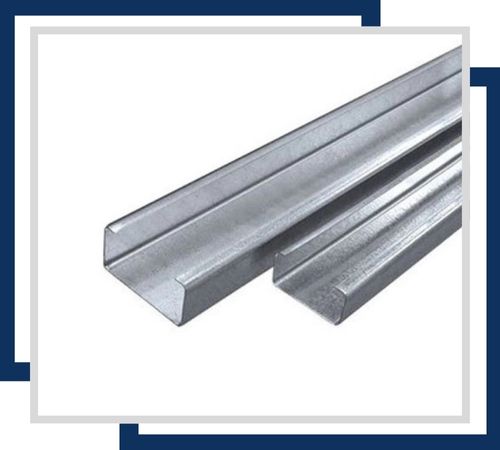

Stainless Steel 304/304L channels are made in Dubai and India to meet the demands of industrial and architectural projects needing corrosion resistance and strength. Available in C and U profiles, these channels provide structural stability and are commonly used in building supports, frames, fabrication works, and infrastructure projects. SS 304 provides high tensile strength and corrosion resistance, while SS 304L, which has lower carbon content, improves weldability and reduces sensitization during fabrication. These channels comply with ASTM A276 and A484 standards and are used extensively in marine, food processing, petrochemical, and structural applications that require durability and reliability.

SS 304/304L contains 18–20% chromium, 8–12% nickel, and carbon levels of ≤0.08% (304) or ≤0.03% (304L). They provide a tensile strength of 485–620 MPa and yield strength of about 170–210 MPa with 35% elongation. The 304L grade enhances weldability and resistance to intergranular corrosion. Both grades are non-magnetic in their annealed state, offer excellent mechanical stability, and can be hot or cold worked easily. These channels maintain their strength and corrosion resistance under different temperatures and atmospheric conditions.

| Standard | ASTM A276, ASTM A479 / ASME SA276, ASME SA479 |

| Condition | HRAP |

| Size Range | Base: 80 to 150 mm Side: 40 to 75 mm |

| Thickness | 5 to 6 mm (depending on size) |

| Grades | 304, 316 |

| Processing | Bar cutting |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 16.00 – 18.00 | 10.00 – 14.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

Stainless Steel 304/304L channels are structural components made from corrosion-resistant stainless steel. They offer high strength and durability, commonly used in construction, industrial support, and architectural applications.

SS 304/304L C channels are stainless steel structural sections with a “C” shape, providing excellent strength, durability, and corrosion resistance. They are used for support and framing in various applications.

Stainless Steel 304/304L U channels are structural sections with a “U” shape, offering high strength and corrosion resistance. They are used for support and reinforcement in construction and industrial applications.

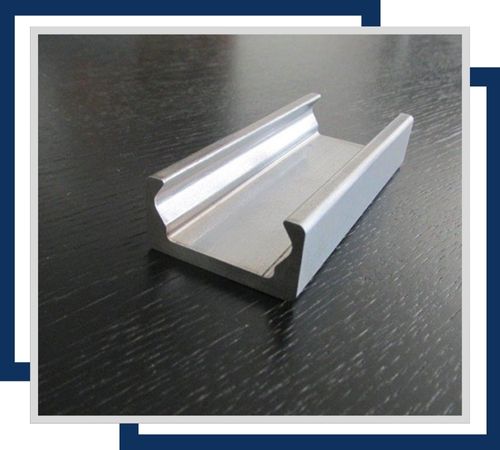

SS 304/304L strut C channels are stainless steel components with a “C” shape, designed for support and framing. They provide excellent strength, durability, and corrosion resistance for various structural applications.

SS 304/304L cold-rolled Unistrut channels are stainless steel channels shaped for versatile support and framing. Produced through cold rolling, they offer high strength, durability, and corrosion resistance for structural applications.

SS 304/304L double C type channels are stainless steel sections with two “C” shapes back-to-back. They provide enhanced strength and stability, ideal for heavy-duty support and framing in construction.

We undertake in-house inspection that is very rigorous to ensure that our stainless steel products meet the highest quality standards. Our team reviews the impact resistance, strength, corrosion resistance, and durability of products to make adherence with industry requirements. We must do all the tests properly. At the buyer’s request, we also provide third party inspection services. It also serps for more visibility by transparency. Moreover, ahead of time delivery is another of our commitments, affecting all orders, for prompt compliance of specified timelines. Hence ensuring efficiency and customer satisfaction.

SS 304/304L channels are used in structural support systems, architectural frameworks, mechanical fabrications, and equipment housings. Their resistance to corrosion makes them suitable for marine structures, wastewater treatment plants, and chemical transport. In construction, they function as beams, brackets, and reinforcement in roofing and wall systems. They’re also found in escalator frames, railway coaches, electrical panels, and general engineering assemblies. Their clean finish and longevity make them well-suited for exposed structural elements in sanitary environments such as commercial kitchens and cleanrooms.

©2024 Harshita Stainless All Rights Reserved.