Harshita Stainless, located in Delhi, India, stands out as a top manufacturer and supplier of high-quality Stainless Steel 317 Tubing, specifically crafted for the toughest industrial settings where corrosion is a major concern. Renowned for its commitment to quality, precision, and reliability, Harshita Stainless delivers tubing solutions that align with international performance and durability standards. The Stainless Steel 317 Tubing is particularly known for its impressive resistance to chemical attacks, especially in acidic and chloride-heavy environments. With a strong focus on customer satisfaction and prompt delivery, Harshita Stainless serves various industries, including chemical processing, marine, pulp and paper, and power generation, offering durable and high-performance tubing options.

Stainless Steel 317 is a high-alloy austenitic stainless steel that contains 18–20% chromium, 11–15% nickel, 3–4% molybdenum, and a maximum of 0.08% carbon. This unique composition provides exceptional resistance to pitting, crevice corrosion, and acidic solutions. The tubing boasts a tensile strength of 515–620 MPa, a yield strength of 205 MPa, an elongation of 35–50%, and a hardness rating of around 85–95 HRB. These characteristics ensure that the tubing retains its structural integrity and corrosion resistance even in aggressive environments, making it particularly suitable for chemical and marine applications.

| ASTM A213 / ASME SA 213 | Standard Specification for SS TP 317L Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

| Shapes | ASME SA213 TP317L Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Surface Finish | BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished, 180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror finish DIN 1.4438 Stainless Steel 317L Tubing or Custom Finish as per customer’s specification |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Relevant Standard | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A554, ASTM A249, ASTM A269, ASTM A270, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 |

| SS 317L | Maximum |

|---|---|

| Ni | 11 – 15 |

| C | 0.035 Maximum |

| Mn | 2 Maximum |

| P | 0.040 Maximum |

| S | 0.03 Maximum |

| Si | 1 Maximum |

| Cr | 18 – 20 |

| Mo | 3 – 4 |

| N | – |

| Element | AISI 317L |

|---|---|

| Density | 8.0 g/cm3 |

| Melting Range | 1454 °C (2650 °F) |

| Tensile Stress | Psi – 75000 , MPa – 515 |

| Yield Stress (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Hardness (Brinell) |

Contact us to get a quick quote for your requirement.

We offers rigorous testing and certification of stainless steel 317 tubing to ensure quality and reliability. Each batch undergoes extensive testing, including chemical composition analysis, mechanical property testing and dimensional verification. Certificates of Compliance (CoC), Mill Test Reports (MTR), and other quality documents have been provided to also ensure transparency.

This tubing is produced without welds, offering superior strength and uniformity. It typically ranges from 1/8″ to 12″ in diameter. It is highly resistant to corrosion, particularly in chloride environments.

Manufactured by welding a strip of stainless steel, this tubing is suitable for applications requiring moderate strength and corrosion resistance. Sizes generally range from 1/4″ to 6″ in diameter. It provides good resistance to corrosive environments, especially those with chlorides.

Designed for use in heat exchangers, this tubing is available in diameters from 1/2″ to 2″ and offers excellent heat transfer properties. It is highly resistant to corrosion, making it ideal for aggressive chemical environments.

This tubing is used for precise measurement and control applications, with sizes typically ranging from 1/16″ to 2″ in diameter. It offers excellent resistance to corrosion and maintains integrity under high pressure.

Engineered for high-temperature applications, these tubes usually come in diameters from 1/2″ to 4″. They provide robust resistance to oxidation and scaling, making them suitable for boiler systems.

U-Tubes are used in various heat exchanger and condenser applications, with sizes commonly from 1″ to 3″ in diameter. They are highly resistant to corrosion and can withstand the thermal stresses of heat exchange processes.

These tubes are specifically designed for condenser systems, with dimensions typically ranging from 1/2″ to 2″ in diameter. They offer excellent resistance to corrosion from steam and other condensate environments.

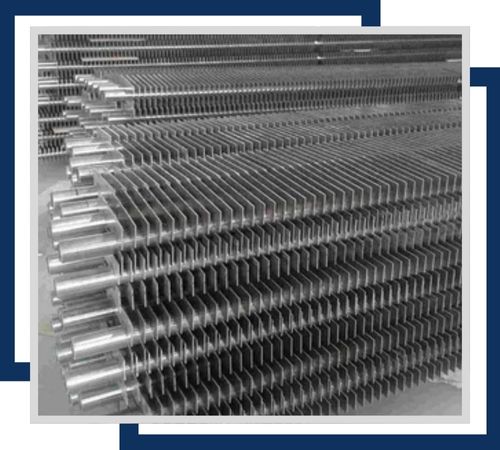

Used for heat transfer applications, these tubes are available in various diameters, often from 1/2″ to 2″. They feature enhanced surface area for improved heat exchange efficiency and are highly resistant to corrosion.

Stainless Steel 317 Tubing finds extensive use across various sectors, including chemical processing, petrochemical, marine, pulp and paper, food and beverage, and wastewater treatment. Its outstanding resistance to chloride-induced corrosion and acidic conditions makes it perfect for applications in heat exchangers, evaporators, condensers, process piping, and storage tanks. Additionally, this tubing is well-suited for marine applications and offshore structures, where it often faces saltwater and harsh environmental conditions. Its robust performance under pressure, heat, and chemical exposure guarantees long-lasting reliability and minimal maintenance, making it a go-to choice for critical and high-stress industrial systems.

©2024 Harshita Stainless All Rights Reserved.