Based in Delhi, India, Harshita Stainless is a reputable brand in the production and distribution of stainless steel 17-4 PH bars. The business offers premium-grade bars made for use in demanding industrial applications, with an emphasis on high-performance stainless steel solutions. Global quality standards are met by the 17-4 PH bars that Harshita Stainless offers, which are renowned for their strength, resistance to corrosion, and exceptional machinability. The business provides services to a variety of industries, such as defence, oil and gas, marine, and aerospace. Through precision manufacturing and timely delivery, Harshita Stainless ensures customer satisfaction with durable, reliable, and cost-effective stainless steel bar solutions.

The martensitic precipitation-hardening stainless steel alloy used to make Stainless Steel 17-4 PH Bars contains trace amounts of niobium, manganese, silicon, and carbon in addition to chromium (15–17.5%), nickel (3–5%), and copper (3–5%). After heat treatment, these bars have exceptional mechanical qualities, such as tensile strength of up to 1100 MPa and hardness of up to 44 HRC. They provide toughness, corrosion resistance, and high yield strength over a broad temperature range. SS 17-4 PH bars are perfect for precision-engineered components because of their minimal distortion, dimensional stability, and ease of heat treatment.

| Grade | C | P | Si | Ni | Cu | Fe | Mn | S | Cr | Cb+Ta |

| SS 17-4 PH | 0.07 | 0.04 | 1.0 max | 3.0 – 5.0 | 3.0 – 5.0 | Bal | 1.0 max | 0.03 | 15.0 – 17.5 | 5 X C / 0.45 |

Contact us to get a quick quote for your requirement.

At Harshita Stainless, all stainless steel 17-4 PH panels have been rigorously tested and quality assured to meet international standards. Our products are certified for durability, tensile strength and corrosion resistance, backed by material test certificates (MTC) and third-party inspections. Trust in our commitment to providing reliable and quality stainless steel solutions.

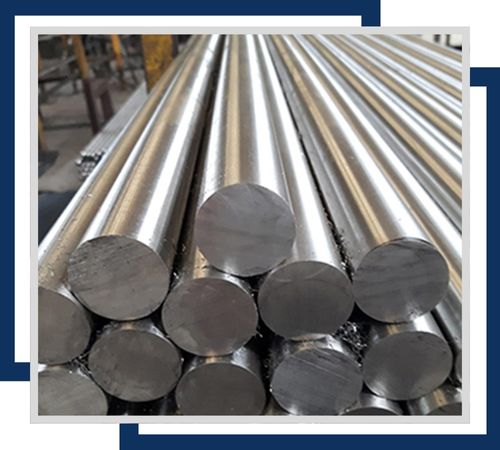

17-4 PH round bars offer high strength and excellent corrosion resistance, ideal for aerospace, marine, and industrial applications, providing durability and reliability in demanding environments.

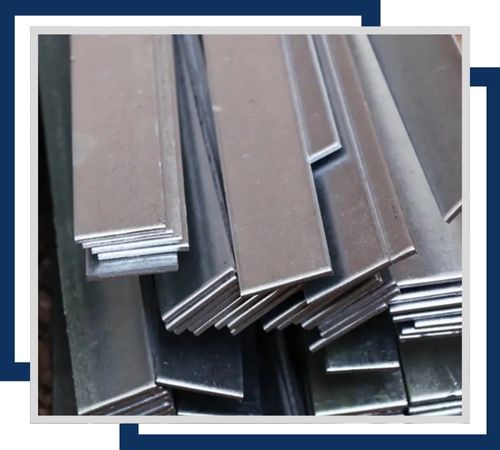

17-4 PH flat bars deliver superior strength and corrosion resistance, suitable for structural components, aerospace parts, and industrial equipment, ensuring long-lasting performance under high stress and corrosive conditions.

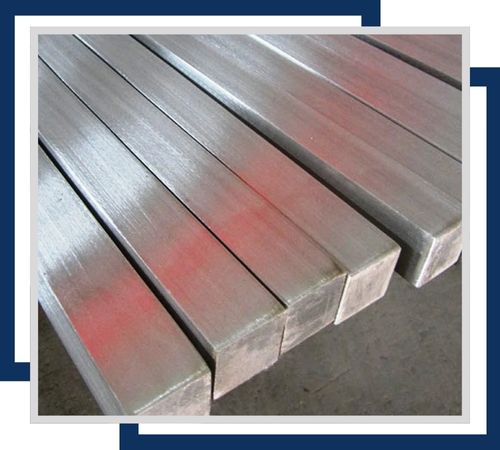

17-4 PH square bars provide exceptional strength and fatigue resistance, perfect for use in aerospace and industrial applications where high performance and durability are required.

17-4 PH rectangular bars are used in high-stress applications, offering excellent strength and corrosion resistance, ideal for aerospace, chemical processing, and industrial components.

17-4 PH hexagonal bars offer high strength and resistance to corrosion, suitable for making aerospace parts, mechanical components, and industrial fittings, ensuring durability in challenging environments.

17-4 PH T-bars provide exceptional performance in aerospace and industrial applications, delivering high strength and corrosion resistance, ideal for structural support and critical components.

Industries that demand high strength, resistance to corrosion, and heat-treated performance make extensive use of stainless steel 17-4 PH bars. They are employed in the aerospace sector to produce landing gear parts, shafts, and turbine components. These bars are utilised for propeller shafts and fasteners in marine applications because they don’t corrode in saltwater conditions. They are also frequently used for valve stems, pump shafts, and pressure-containing components in the nuclear, petrochemical, and power generation industries. They are also utilised in food processing equipment, paper mills, and surgical instruments. They are a favoured option for crucial applications due to their mechanical qualities and adaptability.

©2024 Harshita Stainless All Rights Reserved.