Harshita Stainless, a prominent manufacturer and supplier located in Delhi, India, has made a name for itself by providing top-notch stainless steel products to customers around the globe. They specialize in Stainless Steel 301L Pipes and take pride in offering high-quality, durable piping solutions to clients in Dubai, UAE. With a strong focus on excellence, cutting-edge manufacturing processes, and rigorous quality control, Harshita Stainless guarantees that every product meets international standards. Their Stainless Steel 301L Pipes are perfect for industries that require both corrosion resistance and strength, earning the brand a solid reputation among engineers, contractors, and industrial buyers in the UAE and beyond.

These Stainless Steel 301L Pipes are made up of 16-18% chromium and 6-8% nickel, which gives them outstanding corrosion resistance and strength. The low carbon content improves weldability while ensuring durability. In terms of mechanical properties, these pipes boast a tensile strength of about 485 MPa, a yield strength of 170 MPa, and impressive elongation and toughness, even in harsh conditions. Their non-magnetic quality when annealed, along with high fatigue strength and oxidation resistance, makes them perfect for heavy-duty industrial applications. Harshita Stainless delivers these pipes with precision and consistency, making them suitable for both structural and mechanical uses.

Specifications |

ASTM A240, ASME SA240 |

Dimensions |

ASTM, ASME and API |

Surface |

surface and finish of stainless steel sheets |

Type |

Ferritic Stainless Steel |

Processes |

Hot Rolled,Cold Rolled |

Thickness (mm) |

1.2~200 mm |

Width |

50~4020 mm |

Length |

50~18000 mm |

| Grade | C | Mn | Si | P | S | Cr | N | Ni |

| SS 301L | 0.03 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 16.0 – 18.0 | 0.10 max | 6.00 – 8.00 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 301L | 515 | 205 | 40 % |

Contact us to get a quick quote for your requirement.

We offers the best quality 301L stainless steel pipes. These have undergone rigorous testing in durability, strength, and resistance. Our rigorous testing is done by the chemical composition analysis, mechanical property analysis, and dimensional verification. Appropriate certifications are included with each pipe for compliance with international standards to make it efficient and reliable for use in a variety of industrial applications.

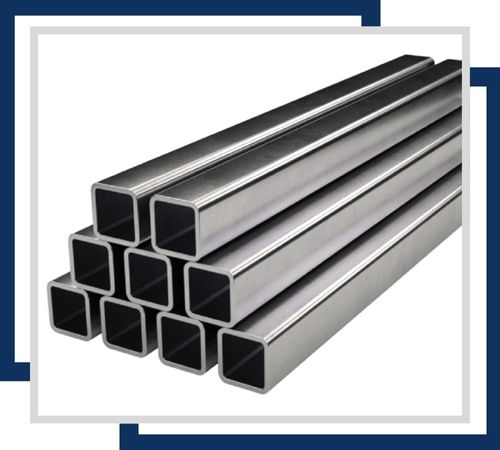

These pipes offer excellent corrosion resistance and are commonly used in structural applications. They come in various sizes, typically 20 mm to 100 mm in side length, with dimensions tailored to specific requirements.

Featuring high corrosion resistance, these pipes are manufactured without weld seams. They are available in diameters ranging from 6 mm to 100 mm and lengths up to 12 meters, making them ideal for high-pressure and high-temperature applications.

Known for their corrosion resistance and cost-effectiveness, Electric Resistance Welded (ERW) pipes are produced in sizes from 15 mm to 300 mm in diameter. They are widely used in various industries due to their strength and precision.

These pipes provide excellent corrosion resistance and are fabricated using the Longitudinal Submerged Arc Welding process. They are available in diameters ranging from 100 mm to 1200 mm and are used for large-scale projects and pipelines.

Offering strong corrosion resistance, round pipes come in 6 mm to 300 mm diameters. They are commonly used in structural, automotive, and industrial applications due to their versatility and durability.

These pipes are known for their corrosion resistance and are produced by welding flat sheets. They are available in various sizes, from 15 mm to 200 mm in diameter, and are ideal for various applications.

The Stainless Steel 301L Pipes from Harshita Stainless are widely utilized across various industries in Dubai, UAE. They are particularly well-suited for applications that demand high strength, corrosion resistance, and excellent formability. Common applications include automotive exhaust systems, chemical processing equipment, marine components, architectural structures, and piping systems in refineries and power plants. Their lightweight yet robust design also makes them ideal for transport and structural engineering projects. The remarkable weldability and resistance to high-temperature oxidation further boost their effectiveness in challenging environments, making them a go-to choice for many industries.

©2024 Harshita Stainless All Rights Reserved.