Based in Delhi, India, Harshita Stainless is a top producer and supplier of stainless steel 410 pipes, providing premium solutions for industrial and structural applications requiring strength and moderate resistance to corrosion. The martensitic grade of stainless steel 410 is renowned for its superior mechanical qualities, resistance to heat, and ability to withstand wear. In order to satisfy both national and international standards, Harshita Stainless provides precisely engineered pipes in a range of sizes and specifications. The company serves important industries like power generation, petrochemicals, automotive, construction, and process engineering, with a strong emphasis on quality assurance, timely delivery, and customer satisfaction.

The main constituents of stainless steel 410 pipes are carbon (0.08–0.15%) and chromium (11.5–13.5%), with iron serving as the base. Small amounts of silicon, phosphorus, sulphur, and manganese may also be present. High strength, good hardness, and moderate corrosion resistance are all provided by SS 410, a martensitic alloy that can be hardened. Tensile strength typically falls between 480 and 750 MPa, yield strength is approximately 270 MPa, and elongation is 20%. The pipes are appropriate for applications subjected to mechanical wear and mildly corrosive environments because they can be heat-treated to improve their mechanical qualities and hardness.

| Dimensions | : | ASTM, ASME and API |

|---|---|---|

| Standard | : | ASTM A312 / ASTM SA312 |

| Size | : | 1/8” NB to 36” NB, 1/4” OD to 36” OD |

| Specialized in | : | Large Diameter Size |

| Outer Diameter | : | 6.35 mm O.D to 114.3 mm O.D |

| Thickness | : | 0.8 mm to 12.7 mm |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Type | : | Welded |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End |

| Grade | Ni | Mn | P | C | S | Si | Cr | Mo | N | |

| 410 | min. | – | – | – | – | – | – | 11.5 | – | – |

| max. | 0.75 | 1.00 | 0.040 | 0.15 | 0.030 | 1.00 | 13.5 | |||

| Tempering Temperature (0C) | Tensile Strength (MPa) | Impact Charpy V (J) | Elongation (% in 50mm) | Yield Strength 0.2% Proof (MPa) | Hardness Brinell (HB) |

| Annealed * | 480 min | – | 16 min | 275 min | – |

| 204 | 1310 | 30 | 16 | 1000 | 388 |

| 316 | 1240 | 36 | 14 | 960 | 325 |

| 427 | 1405 | # | 16 | 950 | 401 |

| 538 | 985 | # | 16 | 730 | 321 |

| 593 | 870 | 39 | 20 | 675 | 255 |

| 650 | 755 | 80 | 23 | 575 | 225 |

Contact us to get a quick quote for your requirement.

We ensures rigorous testing of all stainless steel 410 pipes, including mechanical, chemical and design analysis. Each batch is certified with mill test certificates (MTC), which confirm compliance with international standards such as ASTM, ASME and ISO, and ensure reliability and quality in all products.

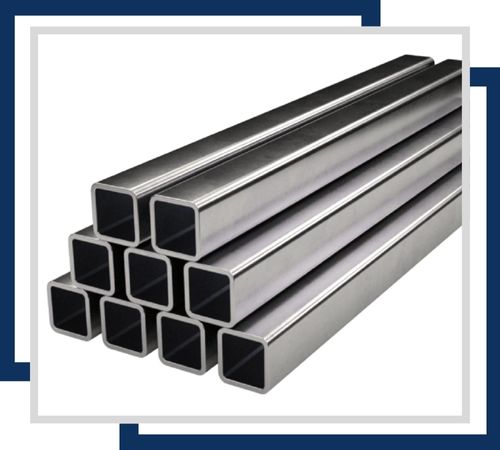

Stainless Steel 410 square pipes offer moderate corrosion resistance and are commonly used in structural applications. They come in various sizes, typically from 20 mm to 100 mm in width and height. They are known for their good machinability and resistance to oxidation.

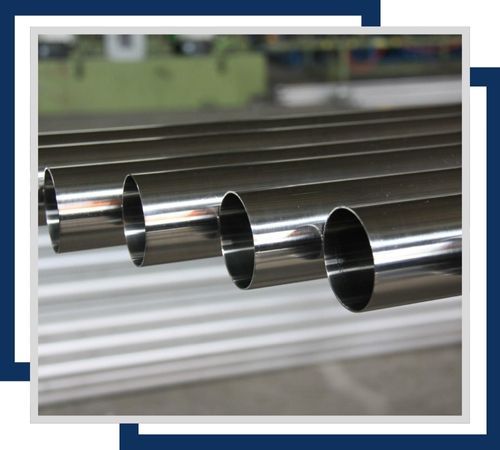

SS 410 Seamless Pipes have moderate corrosion resistance and are ideal for high-stress applications. They are available in sizes ranging from 1/8 inch to 12 inches in diameter. The absence of welded seams provides better strength and reliability in critical environments.

Stainless Steel 410 ERW (Electric Resistance Welded) Pipes feature moderate corrosion resistance and are used in various applications, including construction and industrial. They typically range from 1/2 inch to 24 inches in diameter and offer good weldability and strength.

SS 410 LSAW (Longitudinal Submerged Arc Welded) Pipes exhibit moderate corrosion resistance and are used for high-pressure applications. They are available in sizes ranging from 8 to 60 inches in diameter, offering enhanced strength and durability due to the welding process.

Stainless Steel 410 Round Pipes offer moderate corrosion resistance and are widely used in structural and industrial applications. They are available in diameters ranging from 1/8 inch to 12 inches, providing versatility and strength for various uses.

Stainless Steel 410 Welded Pipes have moderate corrosion resistance and are used in various industries. They are available in sizes from 1/2 inch to 24 inches in diameter. The welding process provides good strength and durability, making them suitable for various applications.

410 stainless steel Because of their strength, hardness, and resistance to mild corrosion and oxidation, pipes are utilised in a variety of industries. They are used in structural elements, manifolds, and exhaust systems in the automotive industry. They are used for heat exchangers and steam lines in refineries and power plants. Their strength in frames, supports, and handrails is advantageous to the construction industry. They are employed in the transportation of mildly corrosive fluids in the chemical industry. They are also appropriate for turbine parts, furnace components, and other high-temperature settings due to their capacity to function in high temperatures and under mechanical stress.

©2024 Harshita Stainless All Rights Reserved.